Gas burner

A gas burner, gas technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems of increasing the final cost of the burner, expensive cooling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

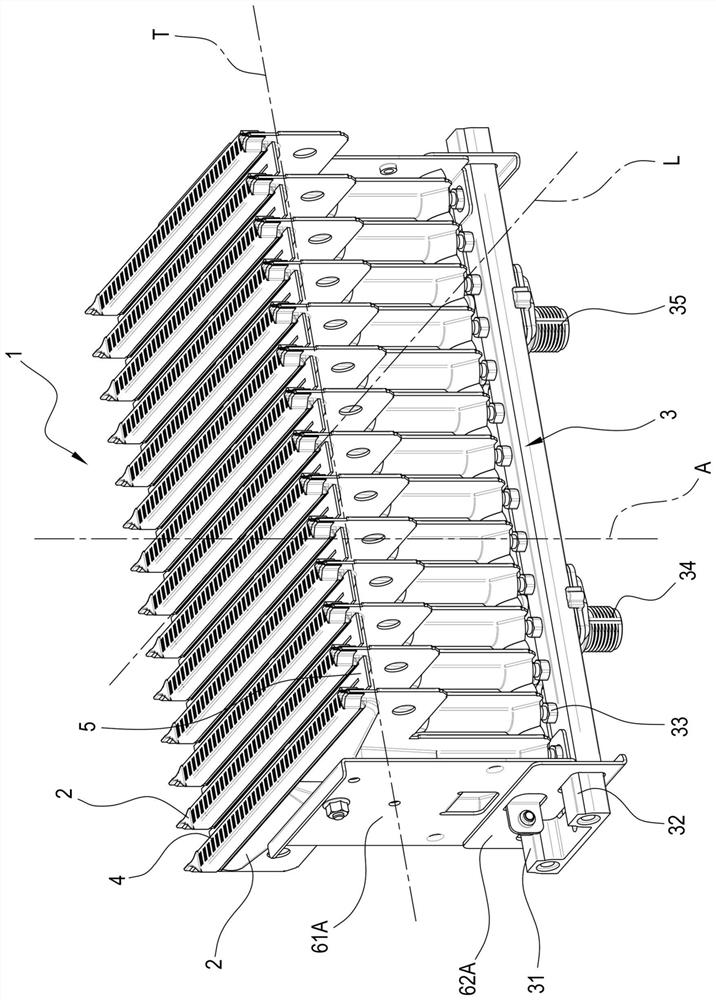

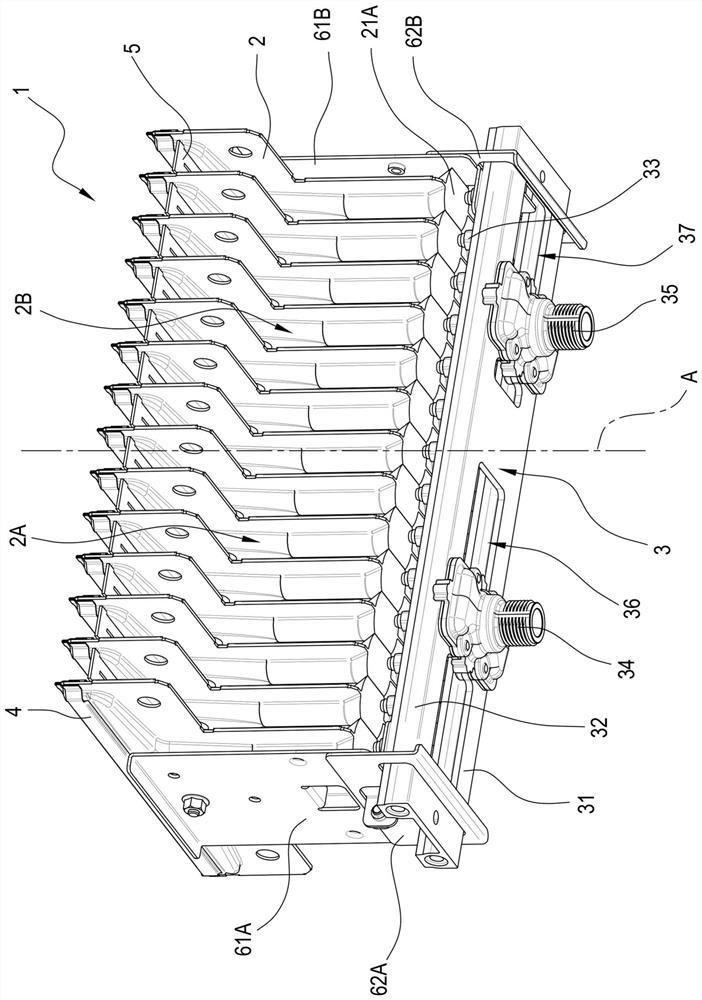

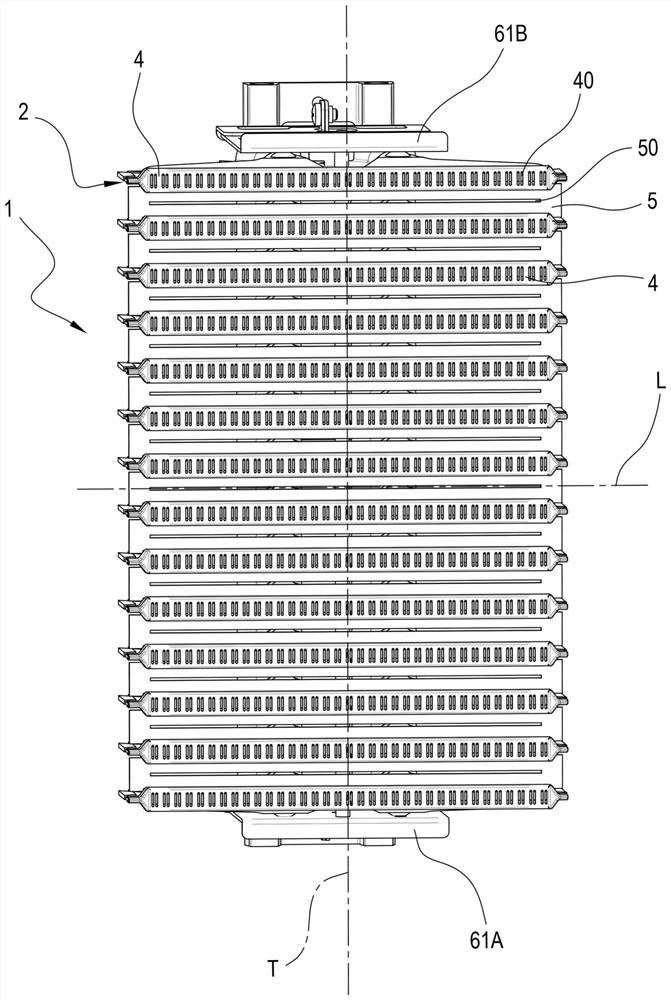

[0041] For the purposes of this disclosure, reference numeral 1 denotes a burner. The burner 1 comprises a plurality of ramp-shaped elements 2 . The ramp-like elements 2 are oriented along respective planes of extension parallel to the longitudinal direction L and the air intake direction A. As shown in FIG. The air intake direction A is at right angles to the longitudinal direction L. The ramp-like elements 2 are arranged side by side along the transverse direction T. As shown in FIG. The transverse direction T is at right angles to the longitudinal direction L and the direction A of the air intake.

[0042]Each ramp-like element 2 comprises a first intake duct 21 and a second intake duct 22 . The first intake duct 21 and the second intake duct 22 are shaped as Venturi tubes, that is to say they comprise a converging part and a diverging part downstream of the converging part. The first intake duct 21 and the second intake duct 22 have respective inlets 21A, 22A and respe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap