Method for analyzing particles deposited on filter disc and sample preparation and analysis equipment thereof

A technology for sample preparation and particle deposition, which is used in the analysis of materials, material analysis by optical means, measurement devices, etc., and can solve problems such as inability to ensure particles, inability to detect transparent particles and particles of the same color of the filter, and inability to detect particles. , to achieve the effect of reducing refraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

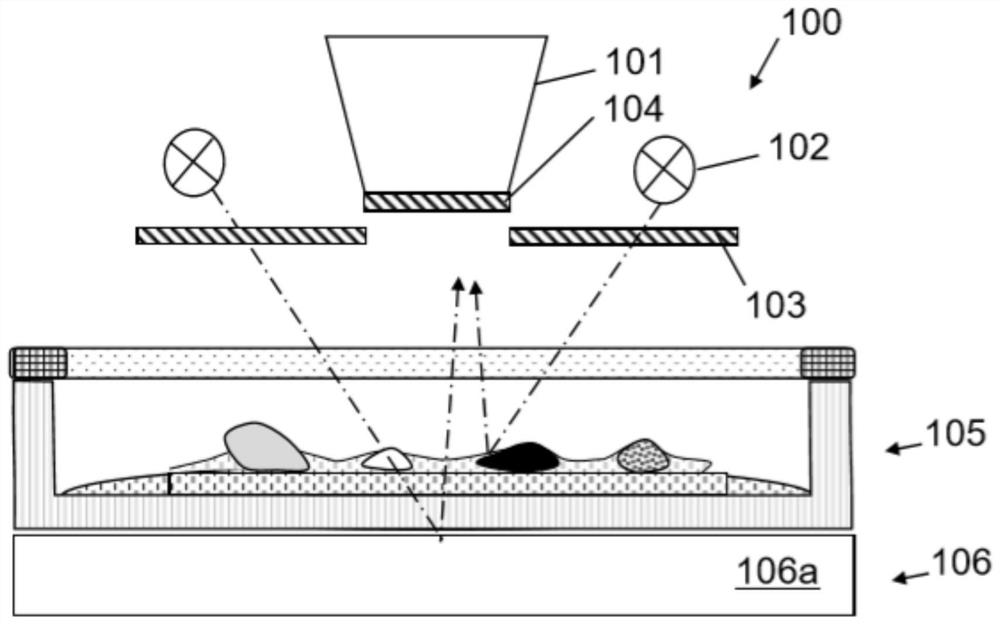

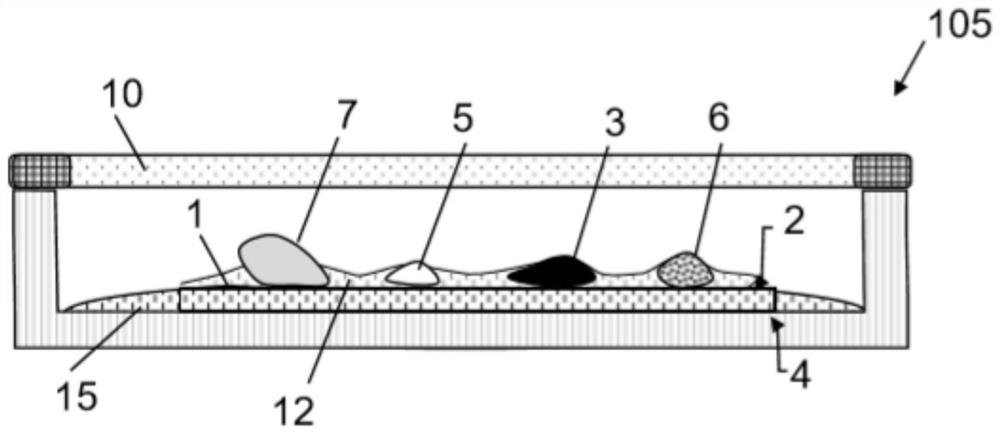

[0046] Example 1: Based on the schematic figure 1 The analysis of filter 1 is described. signal figure 1 , 2 , 3, and 5 demonstrate the first method, using incident optical microscopy to analyze the deposited particles.

[0047] In order to place the filter 1 containing the particles 3, 5, 6, and 7 in an optical microscope for analysis, the particles 3, 5, 6, and 7 need to be fixed on the filter 1 first, and the light transmittance of the filter 1 should be increased.

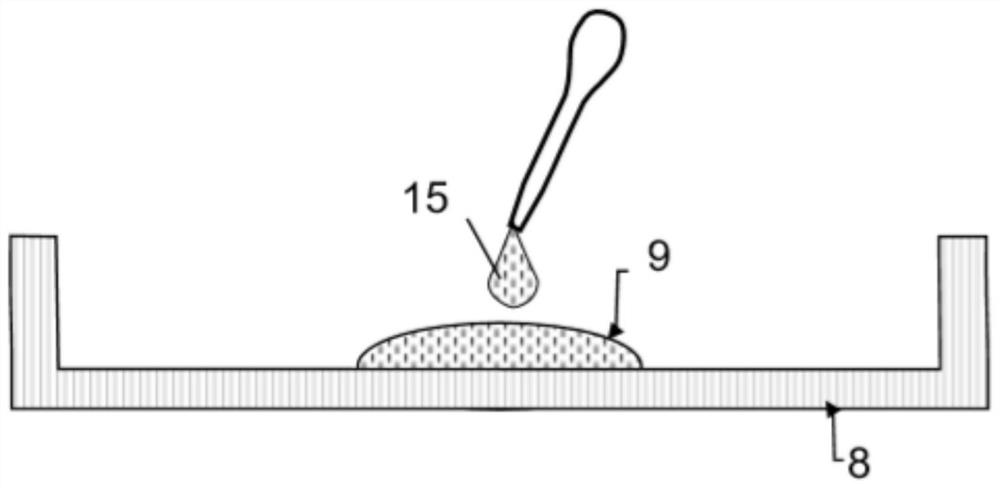

[0048] signal figure 2 0.3 ml of ethylamine nitrate solution 15 is applied on a glass carrier provided in the form of a double-sided slide 8 to form droplets 9 . Ethylamine nitrate can also be applied undiluted to the glass support by mixing ethylamine nitrate and water in a ratio of 2:1 to obtain a water-diluted ethylamine nitrate solution 15. The water-diluted ethylamine nitrate solution 15 has the following advantages over the undiluted ethylamine nitrate solution: its particularly lower viscosity, whi...

Example Embodiment

[0057] Example 2: Schematic Figure 6 to Figure 8 Another method is shown in which the filter 1 is placed on a glass slide 210 instead of the double-sided slide 8 and a water-diluted ethylamine nitrate solution 205 is applied to the top 2 of the filter 1 . The filter 1 was then covered with a cover glass 11 and analyzed with a transmission optical microscope 200 .

[0058] signal Image 6 To demonstrate the procedure for applying a water-diluted ethylamine nitrate solution to filter 1. In order to avoid covering the particles 3, 5, 6, 7 with the ionic liquid, the application should be done at the edge of the filter or at another point. The ionic liquid is preferably applied at the edge of the top 2 of the filter or where it is not covered by the particles 3,5,6,7. Apply until the water-diluted ethylamine nitrate solution 205 diffuses to wet the entire filter.

[0059] signal Figure 7 , cover the filter 1 with a cover glass 11 and bake for 0.5 to 5 hours in the temperatur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap