Flow shop scheduling method based on combination of genetic algorithm and particle swarm optimization

A particle swarm algorithm and workshop scheduling technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low search accuracy and local minimum, and achieve increased evolution quality, increased convergence speed, shortened The effect of convergence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

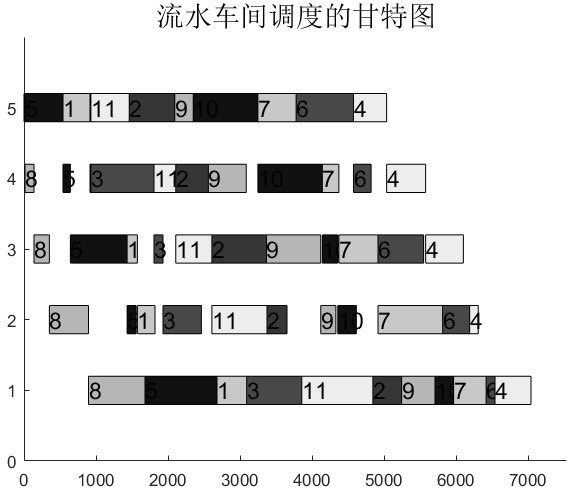

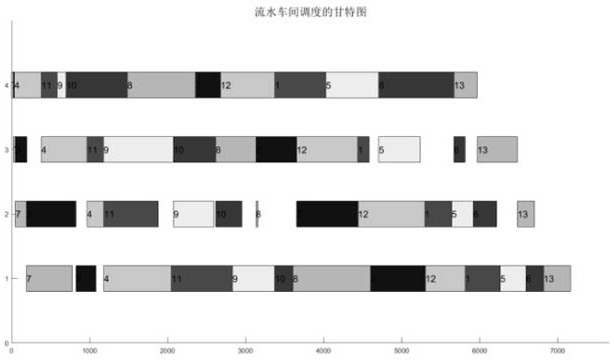

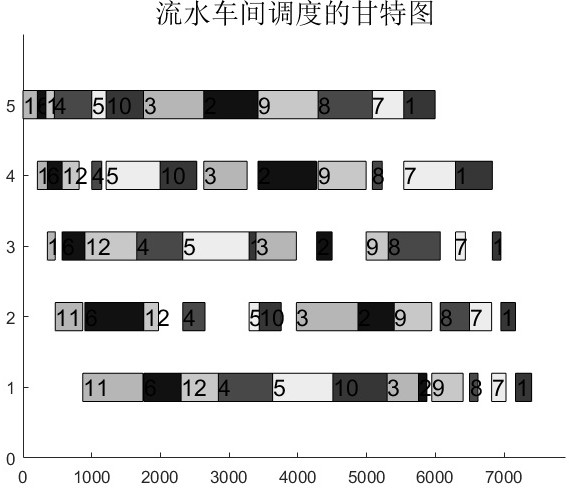

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0037] A kind of flow shop scheduling method based on the combination of genetic algorithm and particle swarm algorithm of the present invention comprises the following steps:

[0038] Step 1: Introduce the weight coefficient in the particle swarm optimization algorithm;

[0039] Step 2: Model the flow workshop, that is, in the flow processing process of n workpieces on m machines, each part is processed in the same order on each machine, and it is agreed that each workpiece is only processed once on each machine. Each machine can only process one workpiece at a time, the processing time and preparation time required for each workpiece on each machine are known, and the processing completion time is the shortest when the corresponding scheduling plan is required;

[0040] Step 3: Apply the particle swarm optimization algorithm to the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com