Intelligent fuse

A fuse, intelligent technology, applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of difficult to adapt to the design, the design cannot fully meet the application requirements, and it is difficult to control the secondary arcing, etc., to achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

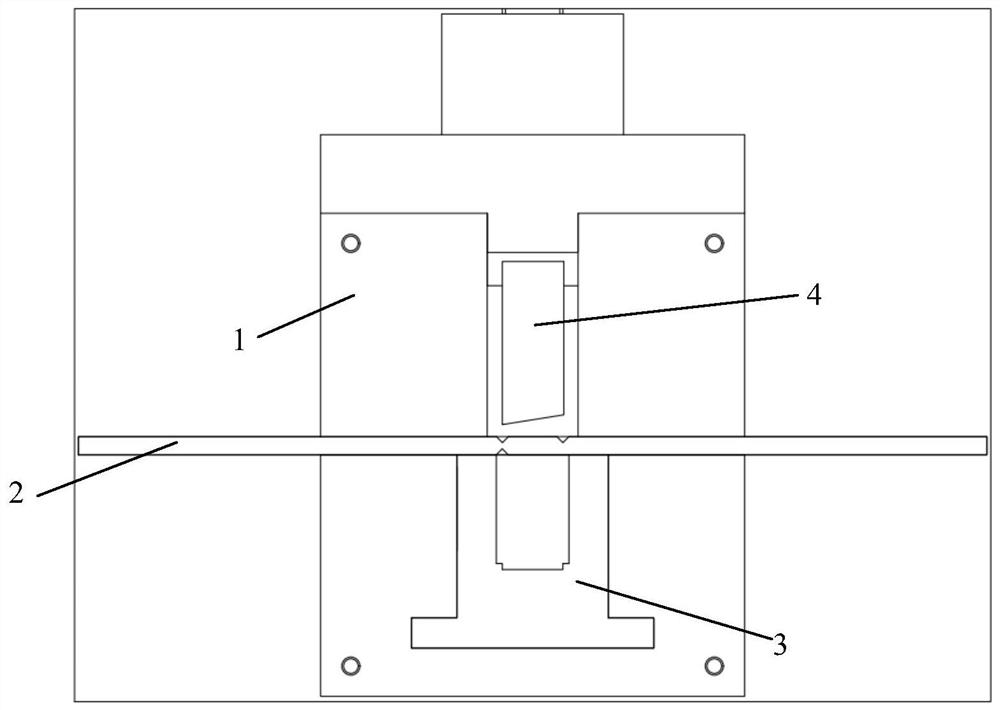

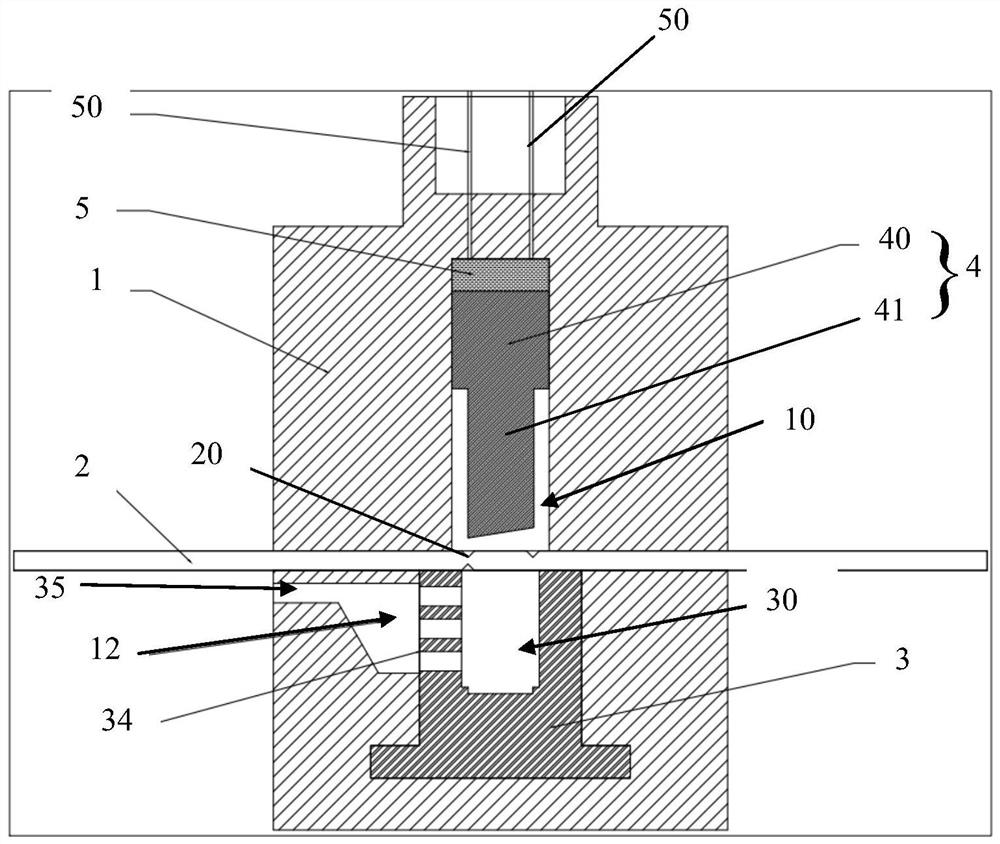

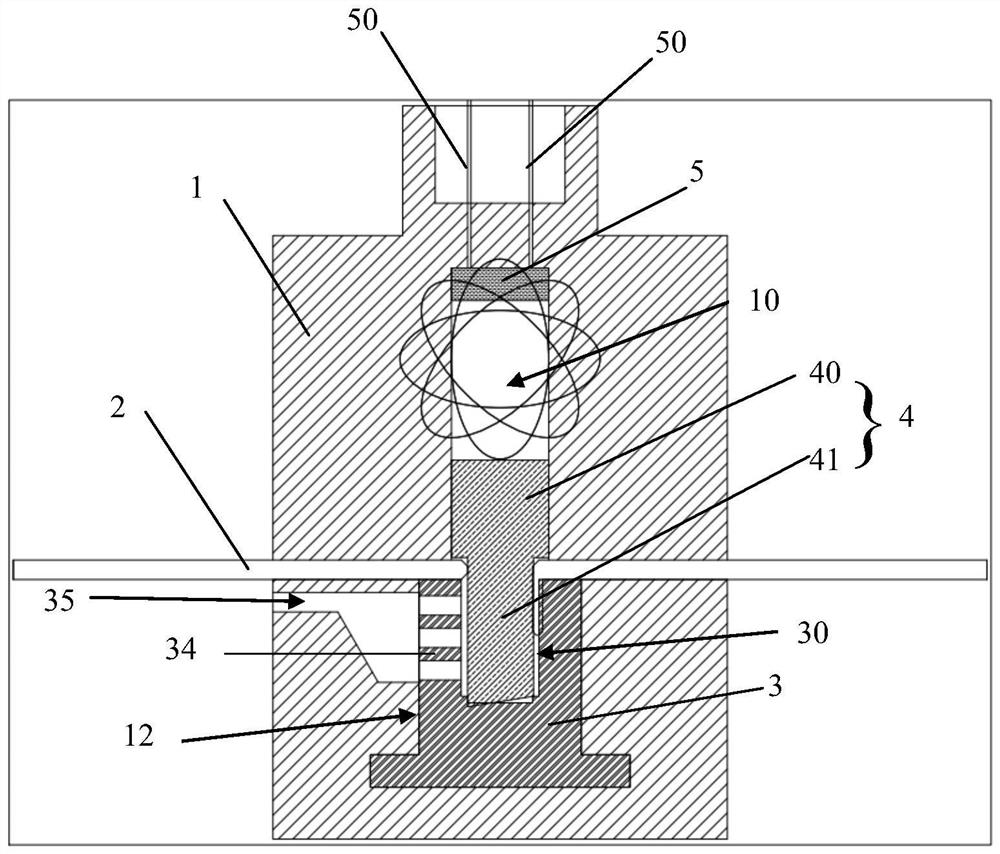

[0028] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention discloses an intelligent fuse, including a housing 1, a conductive plate 2, an arc extinguishing structure 3, a cutting device 4 and a driving device 5, and the housing 1 is provided with a cavity 10 and an arc extinguishing chamber Chamber 12, the cavity 10 communicates with the arc extinguishing chamber 12; the conductive plate 2 is penetrated through the housing 1 and partly located between the cavity 10 and the arc extinguishing chamber 12, and the two ends of the conductive plate 2 can be connected to an external circuit; The arc structure 3 is installed in the arc extinguishing chamber 12 and abuts against the conductive plate 2. The arc extinguishing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com