Protective tube with anti-explosion structure

A fuse and anti-burst technology, applied in the field of fuses, can solve the problems of trouble for staff to clean up, glass pipe burst, uneconomical and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

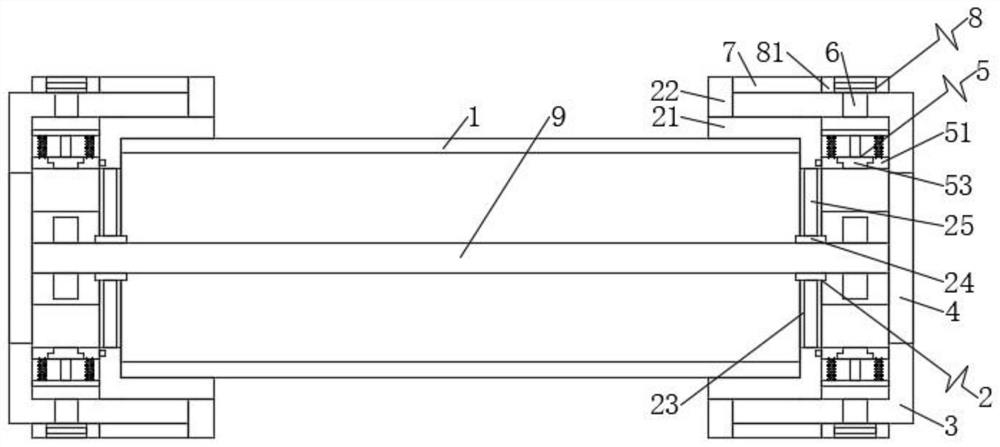

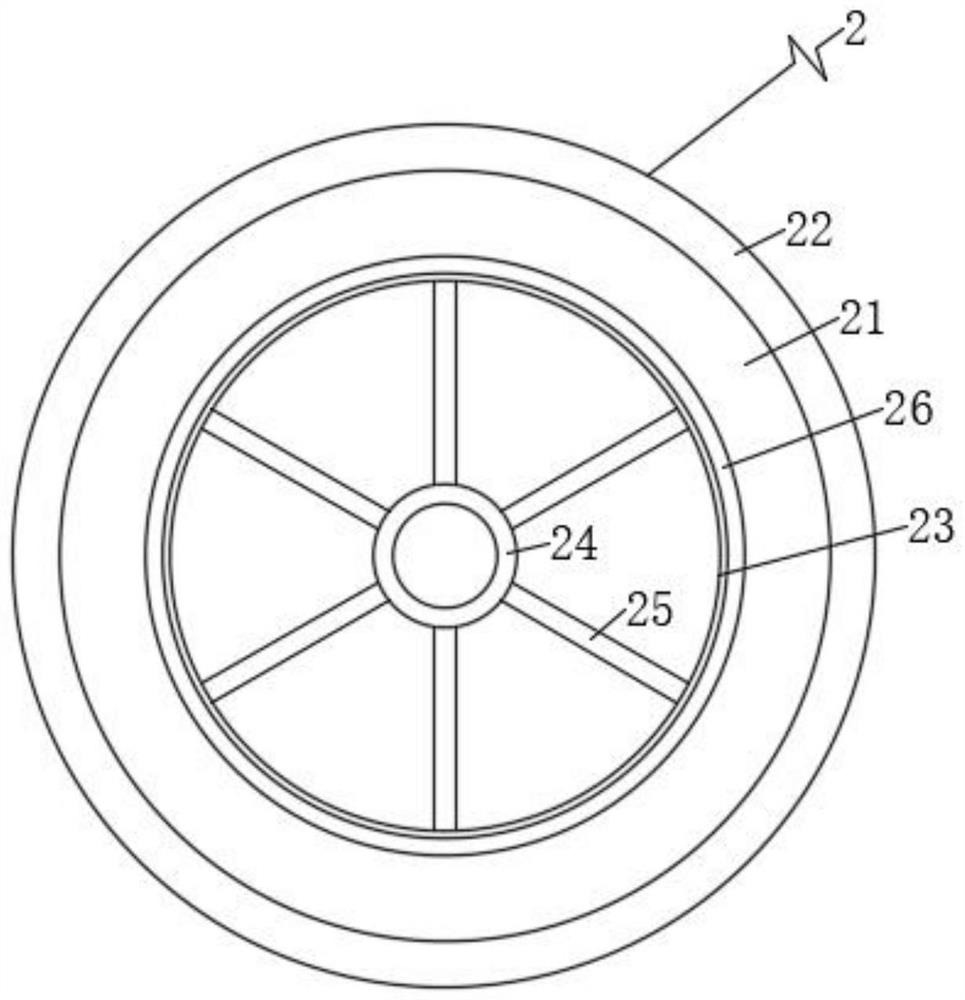

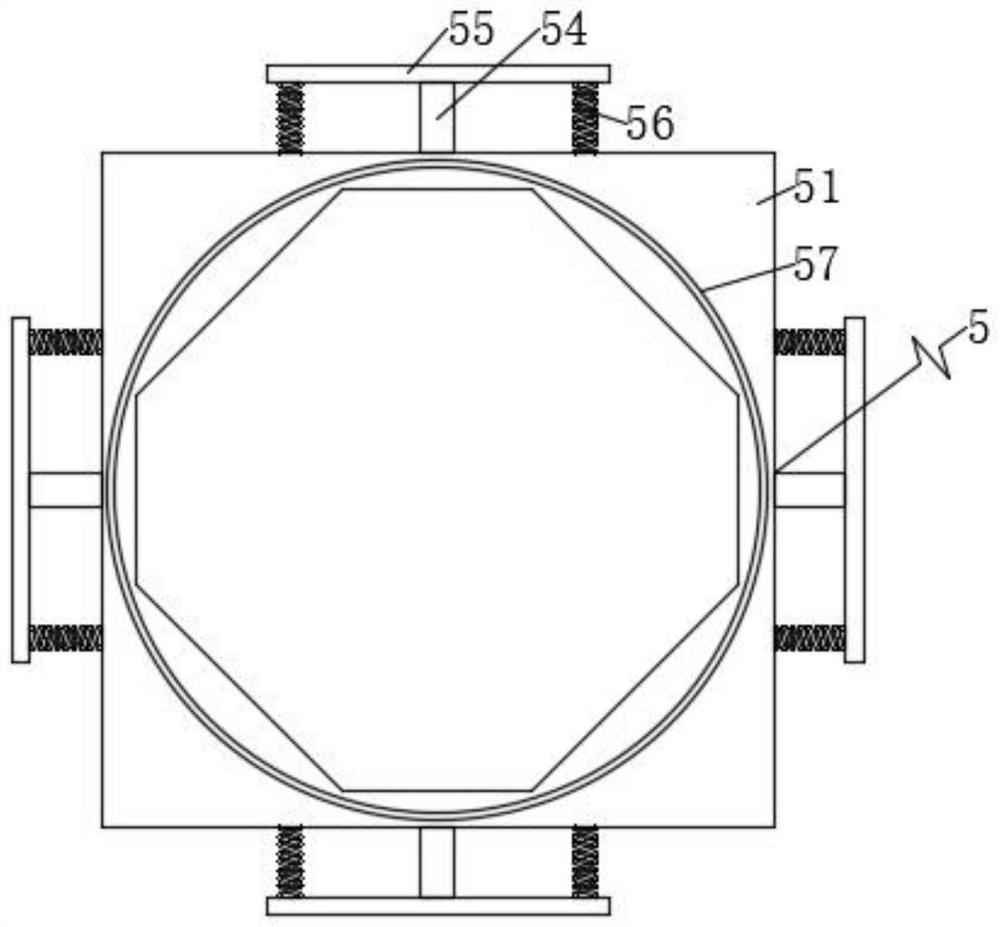

[0026] Example: such as Figure 1-6 As shown, a safety tube with an explosion-proof structure of the present invention includes a glass tube 1, and both ends of the glass tube 1 are connected with a disassembly sleeve 3 through a mounting mechanism 2, and the disassembly sleeve 3 is far away from the glass tube. A conductive plate 4 is fixedly connected to the side wall of one side of the middle part of 1, and a pressure relief mechanism 5 is installed inside the dismounting sleeve 3, and the pressure relief mechanism 5 is connected to the installation mechanism 2 on the same side. The upper and lower ends of the disassembly sleeve 3 and the side wall of the front and back side away from the glass tube 1 are provided with through holes 6, and the outer sides of the plurality of through holes 6 on a single disassembly sleeve 3 are jointly equipped with a dust-proof mechanism 8. A fuse 9 is arranged laterally in the middle of the inner side of the glass tube 1 , and both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com