A kind of quartz tube structure and processing method thereof

A processing method and technology for quartz tubes, applied in the direction of tubes, manufacturing tools, branch pipelines, etc., can solve the problems of high sealing performance requirements at joints, difficult processing, hard and fragile quartz glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is attached Figure 1-10 The application is described in further detail.

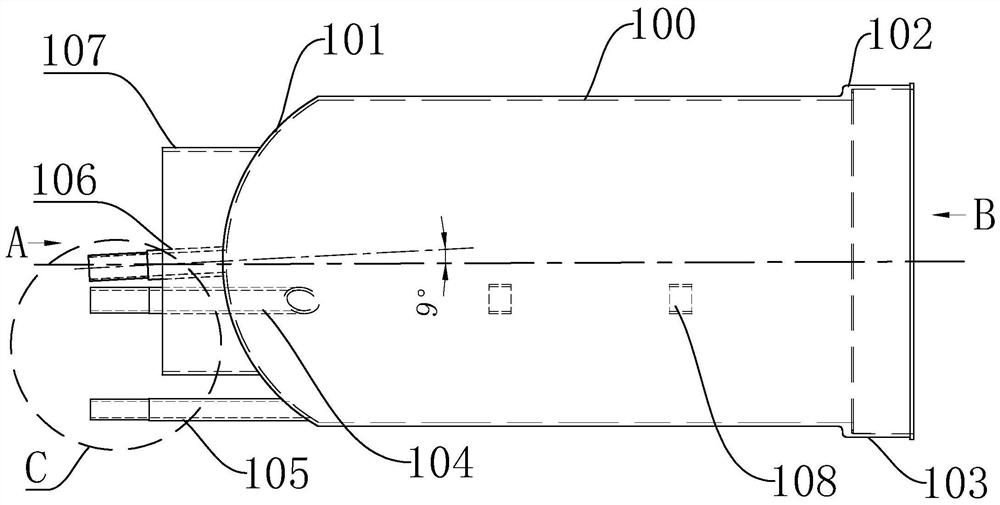

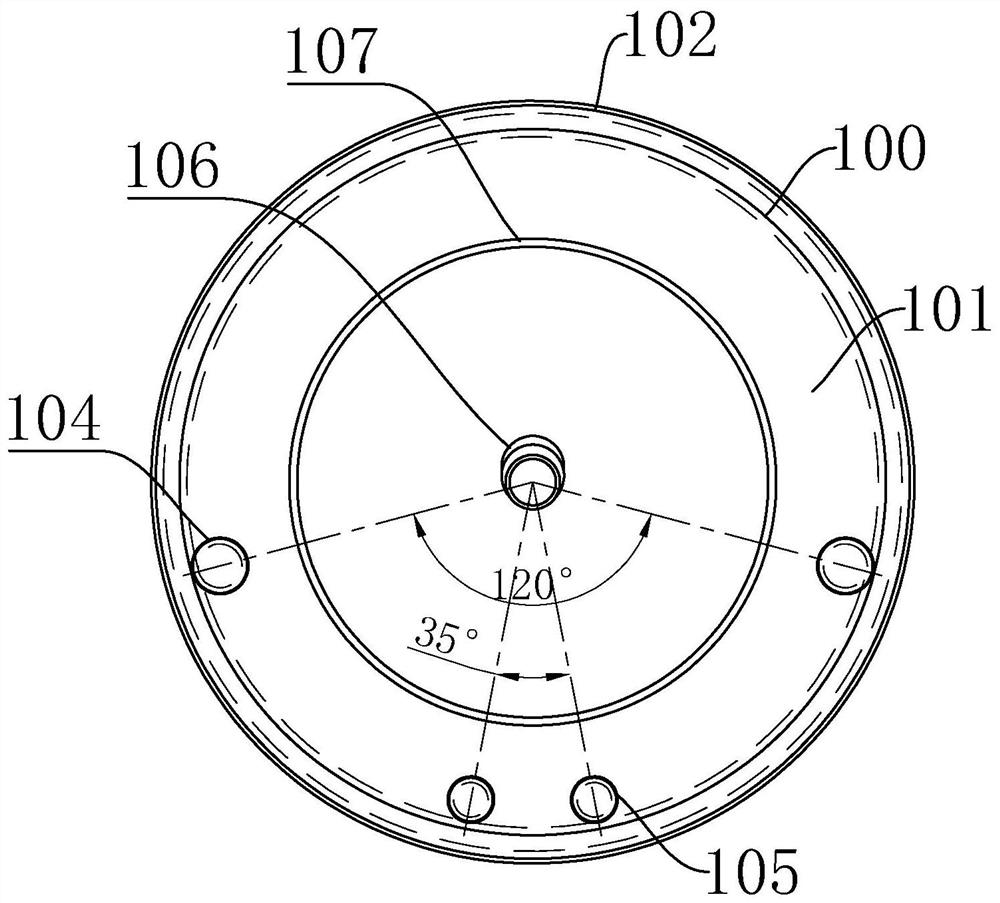

[0054] like figure 1 , 2As shown, a structure of a quartz tube 100 in the embodiment of the present application includes a quartz tube 100, a top sheet 101, an opalescent flange 102, a main flange 103, a first exhaust pipe 104, a second exhaust pipe 105, an air intake pipe 106, The quartz ring 107, the top piece 101 and the suspension ring 108, the quartz tube 100 is tubular with both ends open, the head end of the quartz tube 100 is connected to the coaxial circular top piece 101, and the top piece 101 is formed into an outwardly convex arc by lathe firing.

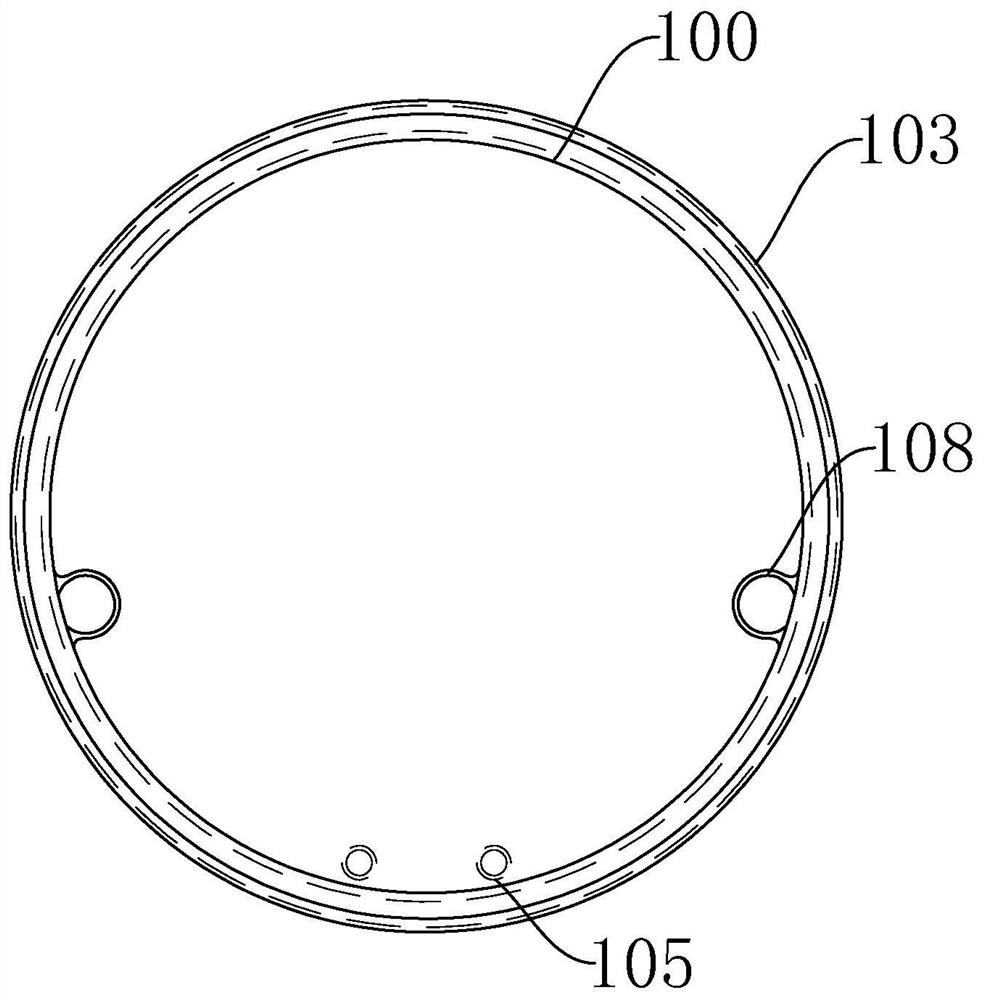

[0055] like Figure 5 , 6 As shown, the main flange 103 is an annular flange. like Figure 7 , 8 As shown, the milky white flange 102 is annular, and the outer end of the milky white flange 102 is provided with an annular sealing groove 1021 . The tail end of the quartz tube 100 is connected to the coaxial opalescent f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com