Battery device and battery device assembly method

A battery device and assembly method technology, which is applied to battery pack components, secondary battery manufacturing, circuits, etc., can solve problems that affect the battery device assembly yield, battery device installation is not in place, scratches to other positions, etc., to achieve Improve the overall reliability and safety, the adhesive layer is uniform and dense, and the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

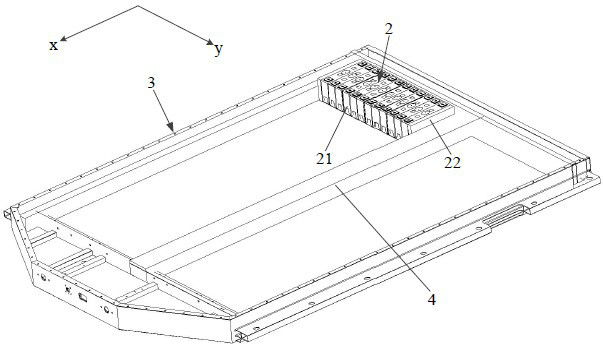

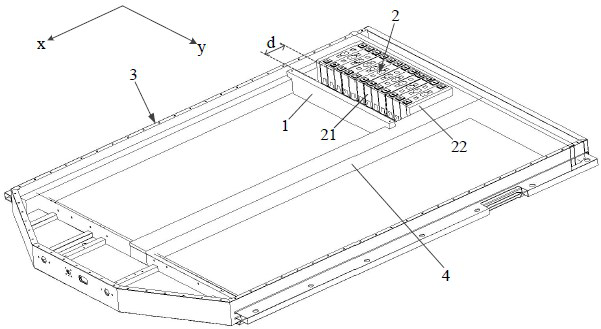

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the exemplary embodiments of the present disclosure with reference to the accompanying drawings in the exemplary embodiments of the present disclosure. The exemplary embodiments described herein are for illustrative purposes only, and are not intended to limit the protection scope of the present disclosure, so it should be understood that various modifications can be made to the exemplary embodiments without departing from the protection scope of the present disclosure. modifications and changes.

[0025] In the related art, the box body of the battery pack is surrounded by beams to form a chamber, and the battery pack is directly inserted into the chamber surrounded by the beams. In this way, if the battery pack and the beam are not bonded by glue, the battery pack will easily displace due to vibration and other reasons during use, and even break away from the chamber, causing danger; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com