Self-adaptive correction method and device for filament current of X-ray equipment

A technology of filament current and correction method, applied in the field of correction, to achieve the effect of self-adaptive correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

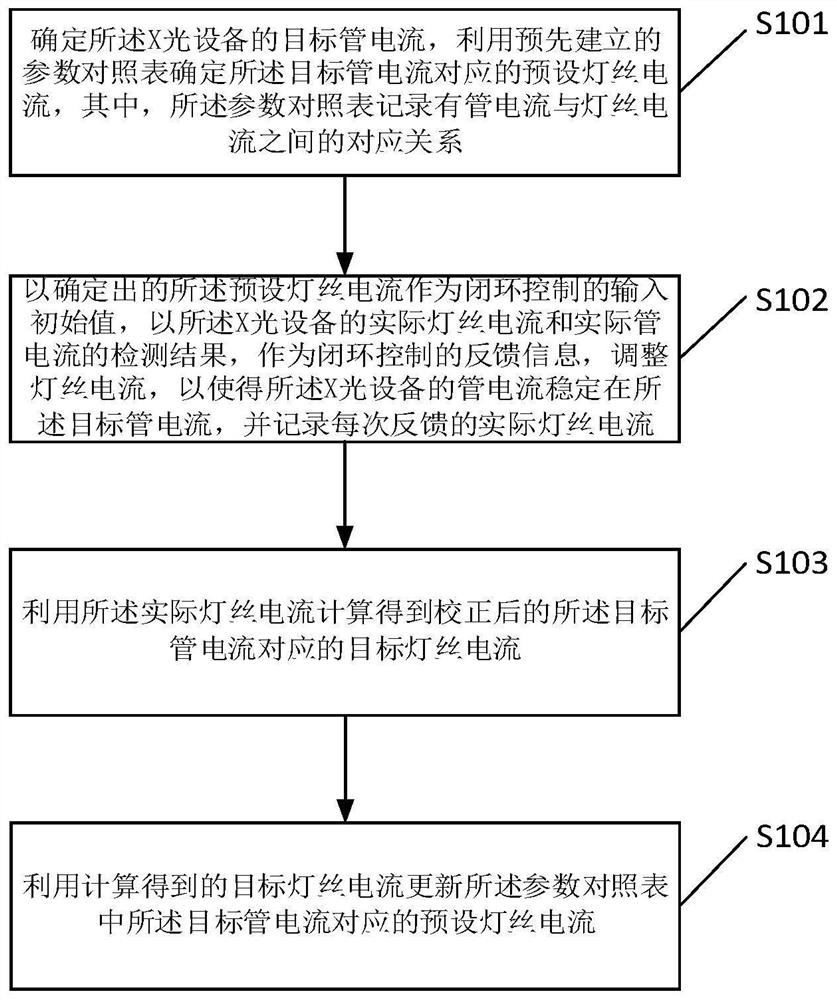

[0046] This embodiment provides an adaptive correction method for the filament current of an X-ray device. The detection method can be executed by a server or other equipment, and the filament current, tube current, etc. are controlled and calculated by the server and other equipment, and the final calculation result is updated at the same time. To the parameter comparison table to determine the accurate target filament current, so as to realize the adaptive correction of the X-ray equipment filament current, such as figure 1 shown, including the following steps:

[0047] Step S101, determine the target tube current of the X-ray equipment, and determine the preset filament current corresponding to the target tube current by using a pre-established parameter comparison table, wherein the parameter comparison table records the difference between the tube current and the filament current. corresponding relationship.

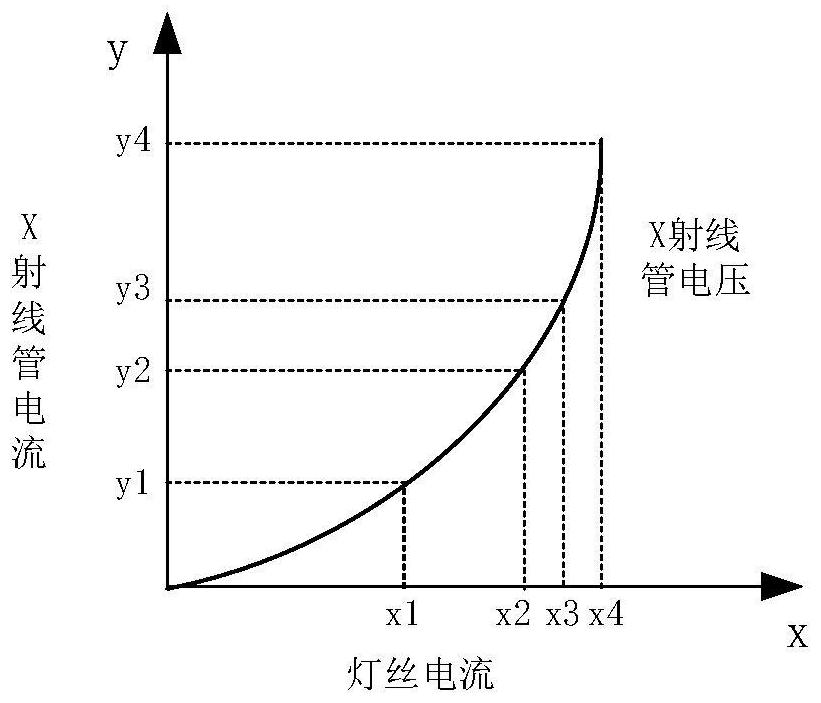

[0048] The tube current of the X-ray tube is determined by th...

Embodiment 2

[0079] This embodiment provides an X-ray equipment filament current adaptive correction device, which can be used to implement the X-ray equipment filament current adaptive correction method in the above-mentioned embodiment 1, and the device can be set inside a server or other equipment, and the module Cooperate with each other, so as to realize the adaptive correction of the filament current of the X-ray equipment, such as Figure 4 As shown, the device includes:

[0080] The comparison module 201 is configured to determine the target tube current of the X-ray equipment, and determine the preset filament current corresponding to the target tube current by using a pre-established parameter comparison table, wherein the parameter comparison table records the tube current and the filament Correspondence between currents;

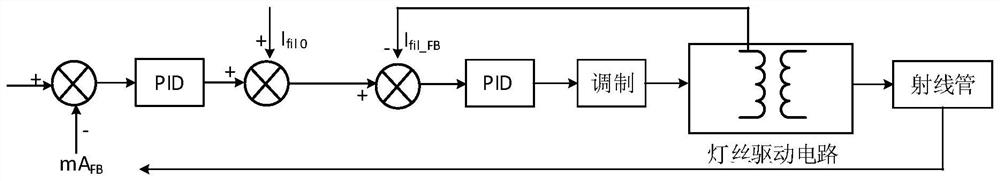

[0081] The adjustment module 202 is configured to use the determined preset filament current as the input initial value of the closed-loop control, and use ...

Embodiment 3

[0087] This embodiment provides a computer device, such as Figure 5 As shown, the computer device includes a processor 301 and a memory 302, wherein the processor 301 and the memory 302 can be connected by a bus or other methods, Figure 5 Take connection via bus as an example.

[0088] The processor 301 may be a central processing unit (Central Processing Unit, CPU). The processor 301 may also be other general-purpose processors, digital signal processors (Digital Signal Processor, DSP), graphics processors (Graphics Processing Unit, GPU), embedded neural network processors (Neural-network Processing Unit, NPU) or other Dedicated deep learning coprocessor, application specific integrated circuit (Application Specific Integrated Circuit, ASIC), field programmable gate array (Field-Programmable Gate Array, FPGA) or other programmable logic devices, discrete gate or transistor logic devices, discrete hardware components and other chips, or a combination of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com