Reaction kettle for processing biopharmaceutical raw materials

A biopharmaceutical and medicinal material processing technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical processes, chemical/physical/physical-chemical processes, etc. problem, to achieve the effect of increasing the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

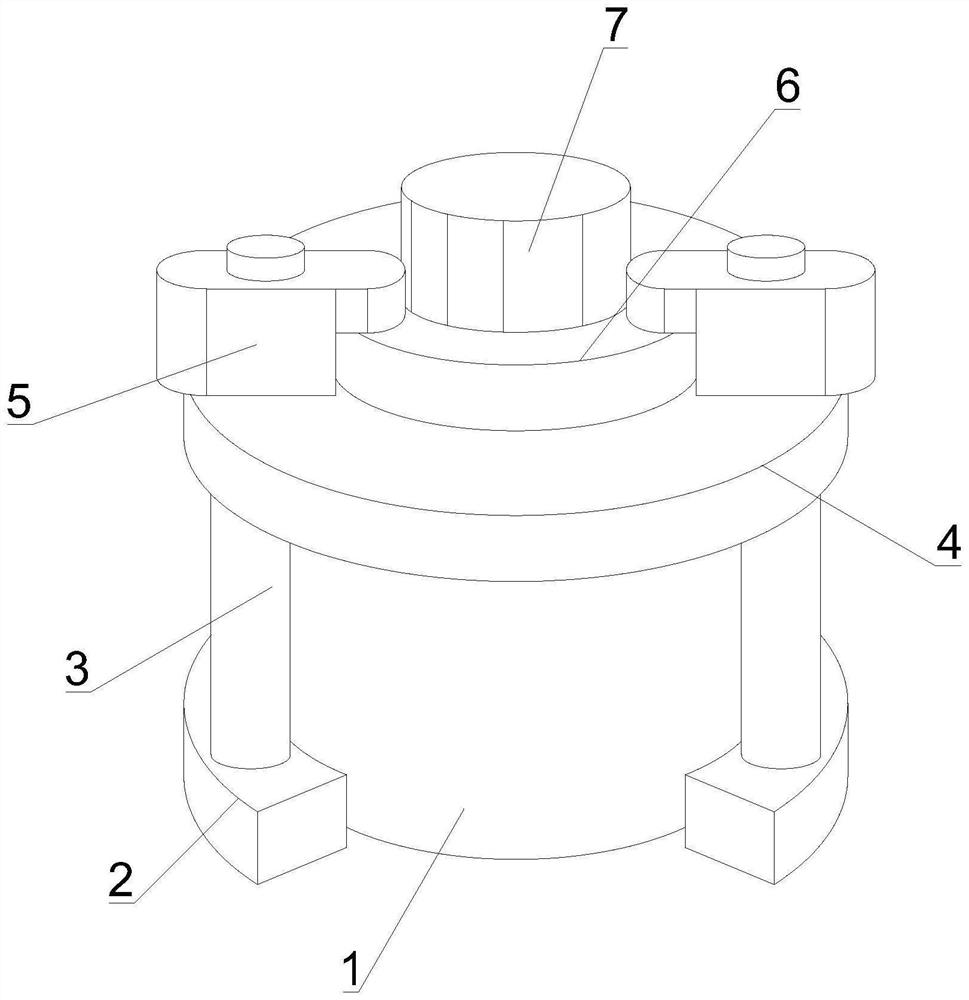

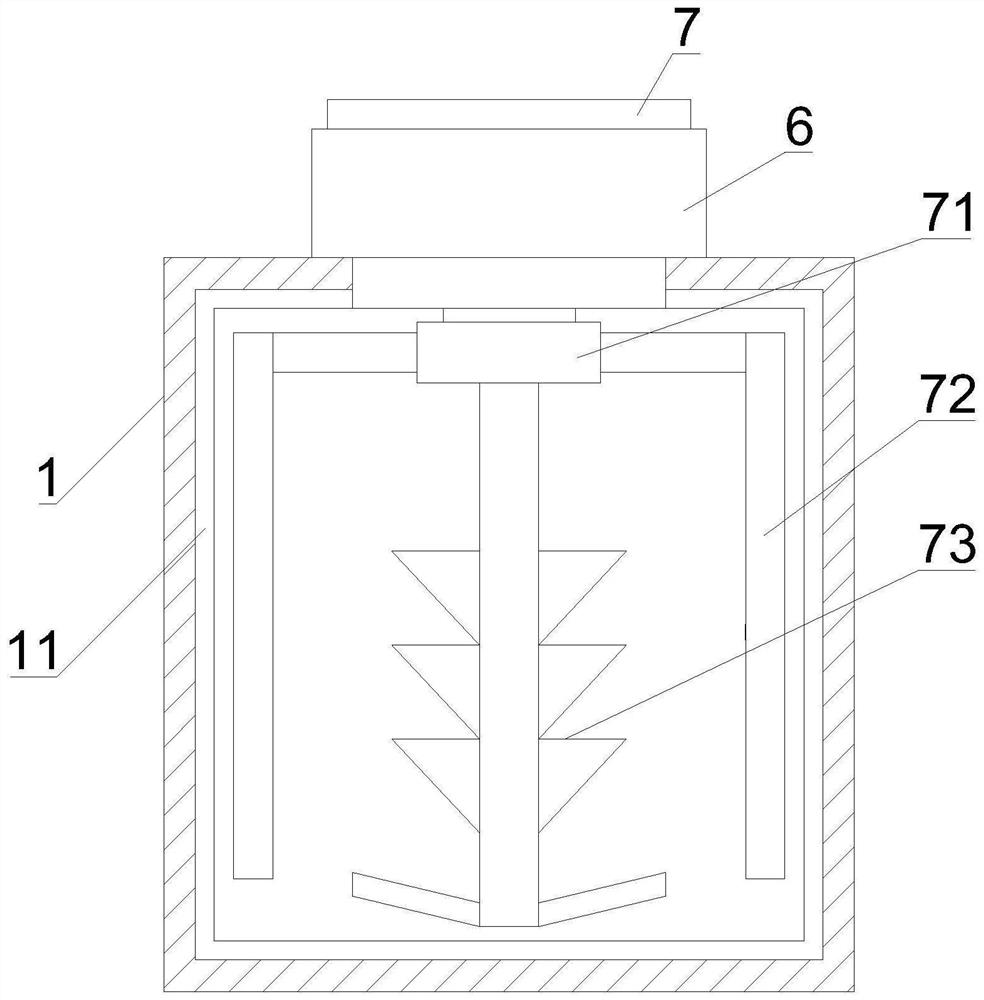

[0039] Such as Figure 1-8 As shown, the present invention provides a biopharmaceutical raw material processing reaction kettle, comprising a medicinal material processing reaction kettle 1, a hollow disc 4, a top sealing cover 6 and a rotating agitator 7, and the top outer surface of the medicinal material processing reaction kettle 1 is movable Hollow disc 4 is sleeved, and the top of medicinal material processing reaction kettle 1 is movably sleeved with plug sealing cover 6, and the top of plug sealing cover 6 is detachably installed with rotating agitator 7, which includes a cleaning rod 72, medicinal material The outer surface of the bottom of both sides of the processing reactor 1 is movably overlapped with a footing arc block 2, and the top outer surface of the footing arc block 2 is detachably connected with a support column-3, and one end of the support column-3 is detachably connected to the On the edge positions of both sides of the bottom of the hollow disc 4, the...

Embodiment 2

[0042] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a casing 721 is detachably installed on the right outer surface of the cleaning rod 72, and the left inner surface of the casing 721 can be The detachable type is connected with support column two 722, and one end of support column two 722 is fixedly connected with elastic soft ring 723, and one side outer surface of elastic soft ring 723 is detachably connected with telescopic plate 724, and the outer right side of telescopic plate 724 Cleaning cutter head device 725 is arranged on the surface, and the front of cleaning cutter head device 725 is provided with running water groove 726, and running water groove 726 runs through the both sides outer surfaces of cleaning cutter head device 725, and the top inner surface of running water groove 726 is provided with Square groove, the inner surface of the inner side of the square groove is rotatably co...

Embodiment 3

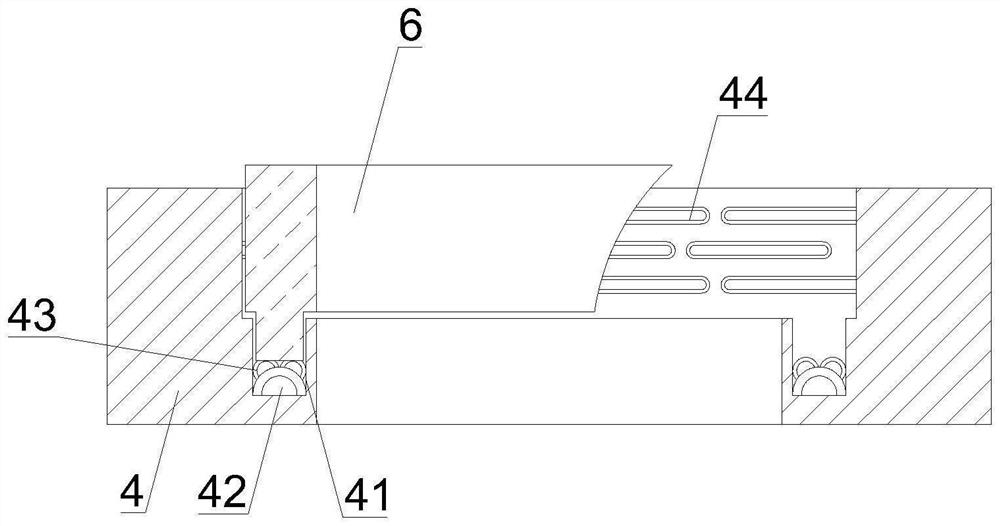

[0045] Such as Figure 1-8 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, the top outer surface of hollow disk 4 is provided with sunken groove 41, and the bottom inner surface of sunken groove 41 can be The detachable connection is provided with a semicircular soft block 42, the top of the semicircular soft block 42 is biased to both sides and the outer surface is provided with a deformed and extruded filled soft block 43, and the top surface of the deformed and extruded filled soft block 43 is movable with the bottom surface of the top sealing cover 6 Overlapping, the inner surface of the hollow disc 4 is provided with strip-shaped soft sealing blocks 44, and the rows of the strip-shaped soft sealing blocks 44 are interlaced with each other.

[0046] In this embodiment, the bottom of the plug sealing cover 6 is inserted into the interior of the recessed groove 41 to be bonded with the deformed extrusion filling sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com