Test tube cleaning equipment for biological experiment

A technology for cleaning equipment and biological experiments, which is applied in the field of test tube cleaning equipment for biological experiments, and can solve problems such as time-consuming, labor-intensive cleaning, low cleaning efficiency, and cumbersome operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

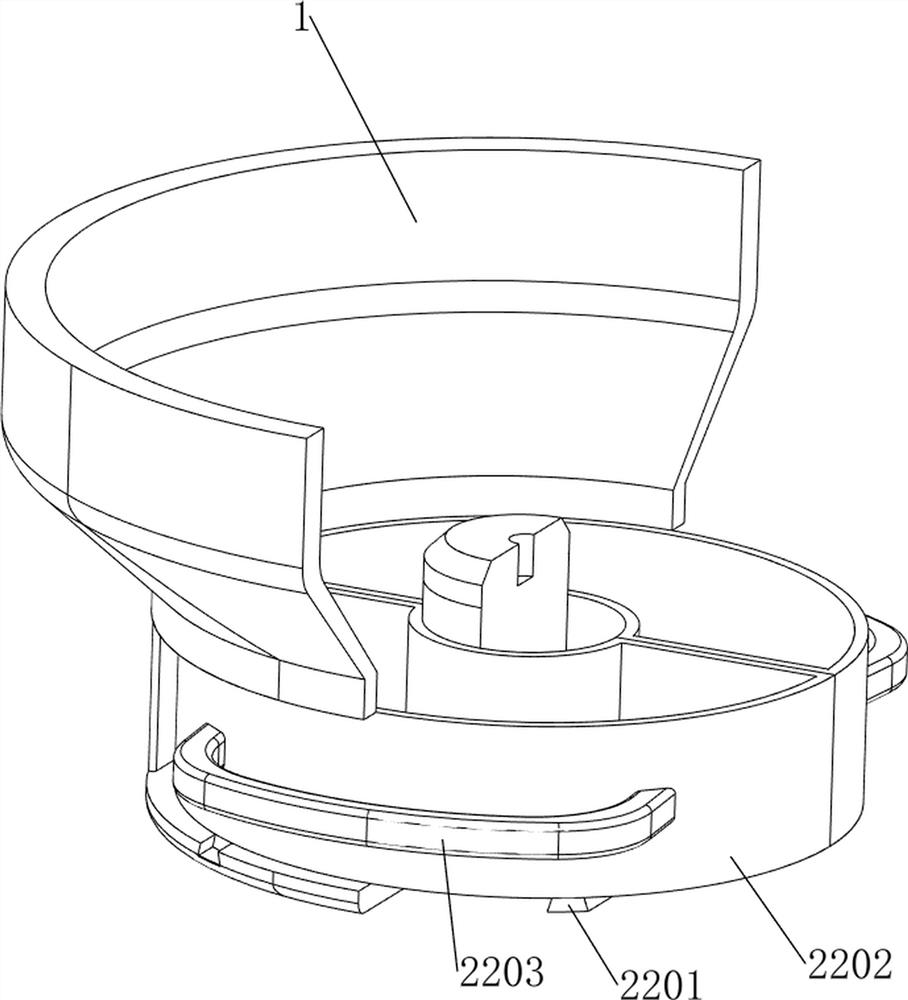

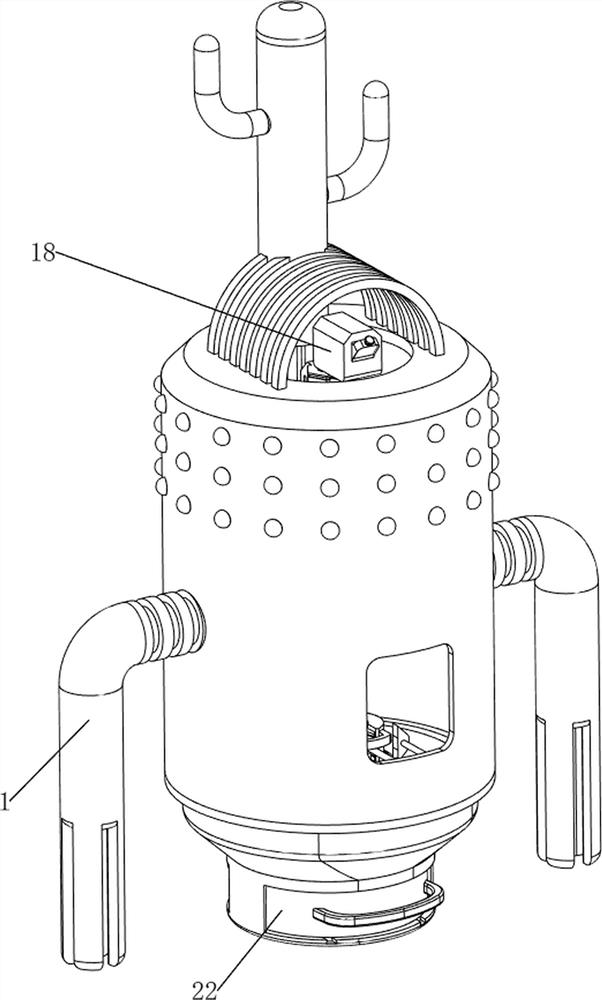

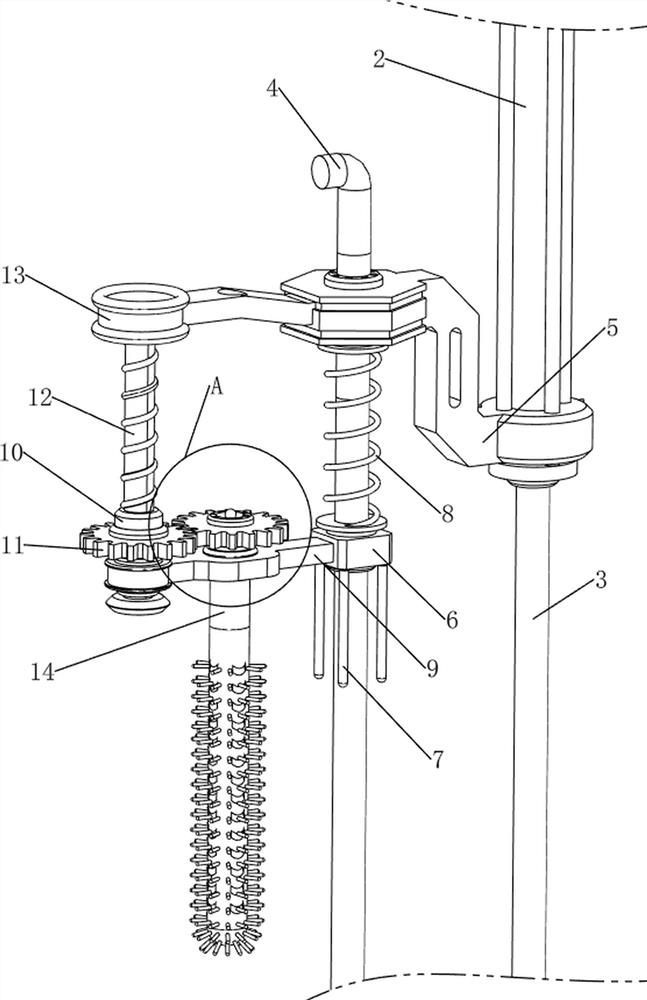

[0087] A test tube cleaning device for biological experiments, such as Figure 1-Figure 8 As shown, it includes a frame 1, a cylinder 2, an air rod 3, a first support rod 4, a first mounting block 5, a second mounting block 6, a touch lever 7, a first return spring 8, and a first mounting plate 9 , the first nut 10, the first spur gear set 11, the first screw rod 12, the mounting plate 13, the cleaning rod 14, the extruding rod 15, the second mounting plate 16, the drying mechanism 17 and the water discharge mechanism 18, the inner wall of the frame 1 The rear side of the upper part is equipped with a cylinder 2, the bottom of the cylinder 2 is provided with a first mounting block 5, and the middle of the lower part of the inner wall of the frame 1 is provided with a first support rod 4, and the first support rod 4 is connected with the top of the first mounting block 5. The telescopic rod is provided with an air rod 3, the first support rod 4 is slidably provided with a secon...

Embodiment 2

[0094] On the basis of Example 1, such as Figure 1-Figure 2 and Figure 8-Figure 13 As shown, it also includes a turning mechanism 19. The turning mechanism 19 includes a second mounting rod 1901, a third spur gear 1902, a third support rod 1903 and a first rack 1904. The front side of the second mounting plate 16 is rotatably provided with The second installation rod 1901, the front side of the second installation rod 1901 is provided with a third spur gear 1902, the front side of the lower part of the inner wall of the frame 1 is provided with a third support rod 1903, and the upper part of the third support rod 1903 is provided with a first rack 1904, The first rack gear 1904 cooperates with the third spur gear 1902 .

[0095] When the second mounting plate 16 moves upward, the upward movement of the second mounting plate 16 will cause the second mounting rod 1901 and the third spur gear 1902 to move upward, and the third spur gear 1902 will move upward to contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com