Automatic embossing machine for generating surface texture of decorative wood plate

A surface texture and decorative technology, applied in the field of automatic embossing machines for surface texture generation of decorative wood panels, can solve the problems of reduced texture clarity, poor processing quality of panels, and easy springback, and achieves improved practicability and efficiency. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

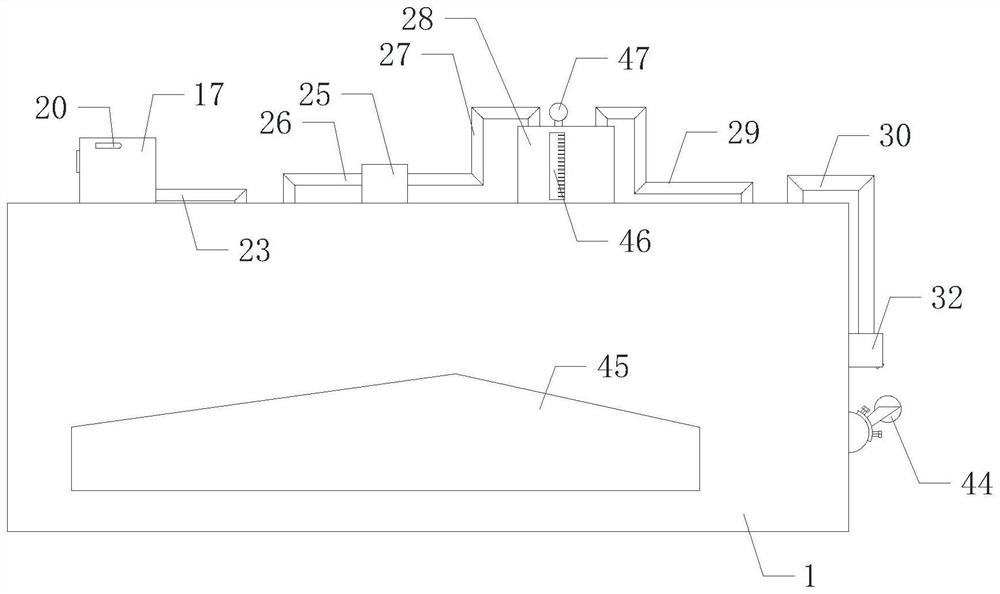

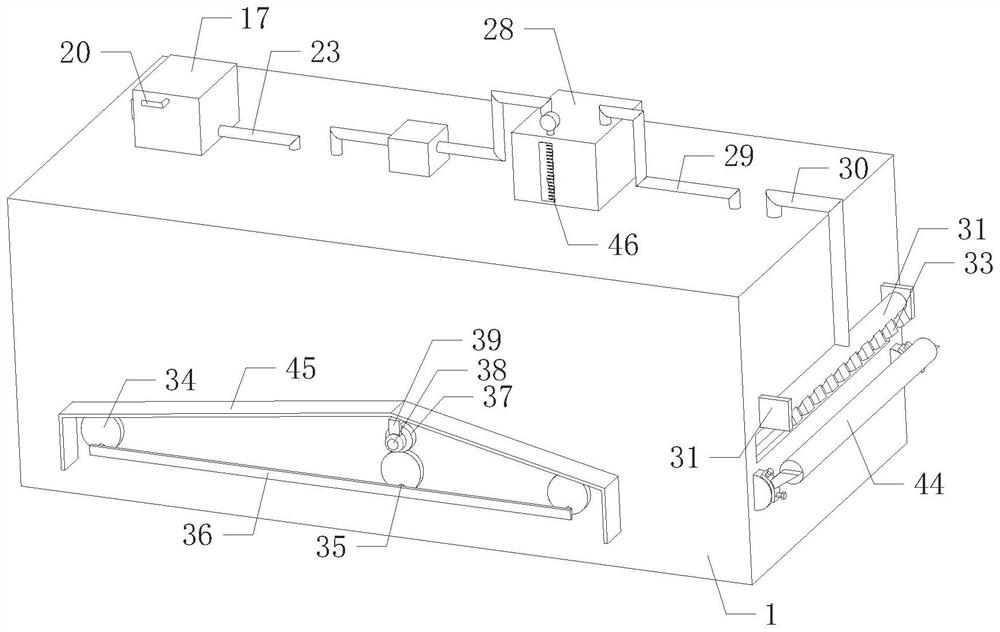

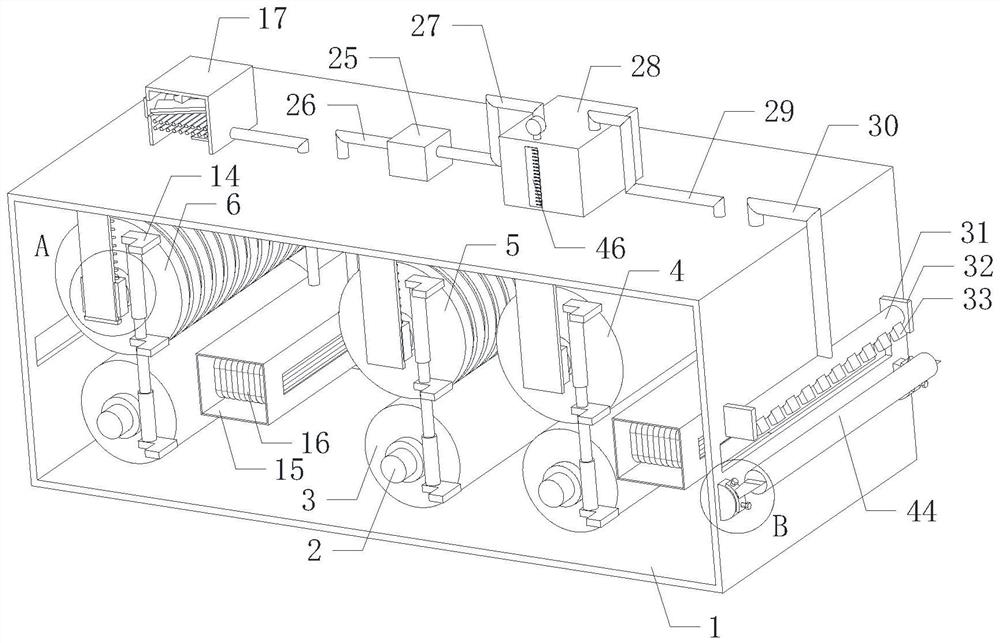

[0021] like Figure 1 to Figure 6 As shown, an automatic embossing machine for surface texture generation of decorative wood panels of the present invention, when it is working, the refrigeration mechanism and the heating mechanism are turned on, and the refrigeration mechanism sucks in the outside air to cool and form a low-temperature airflow, which enters the left side The spiral heat pipe 16 flows into the heating mechanism. The heating mechanism heats the air to form a high-temperature airflow. The high-temperature airflow enters the right spiral heat pipe 16, and the power mechanism is turned on. The power mechanism drives the three groups of rotating shafts 2 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com