High-power-density rack-mounted load

A high power density, rack-mounted technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems affecting the normal use of the load, high load surface temperature, small size and high power, etc., to achieve easy batch Production and assembly, large cooling power and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

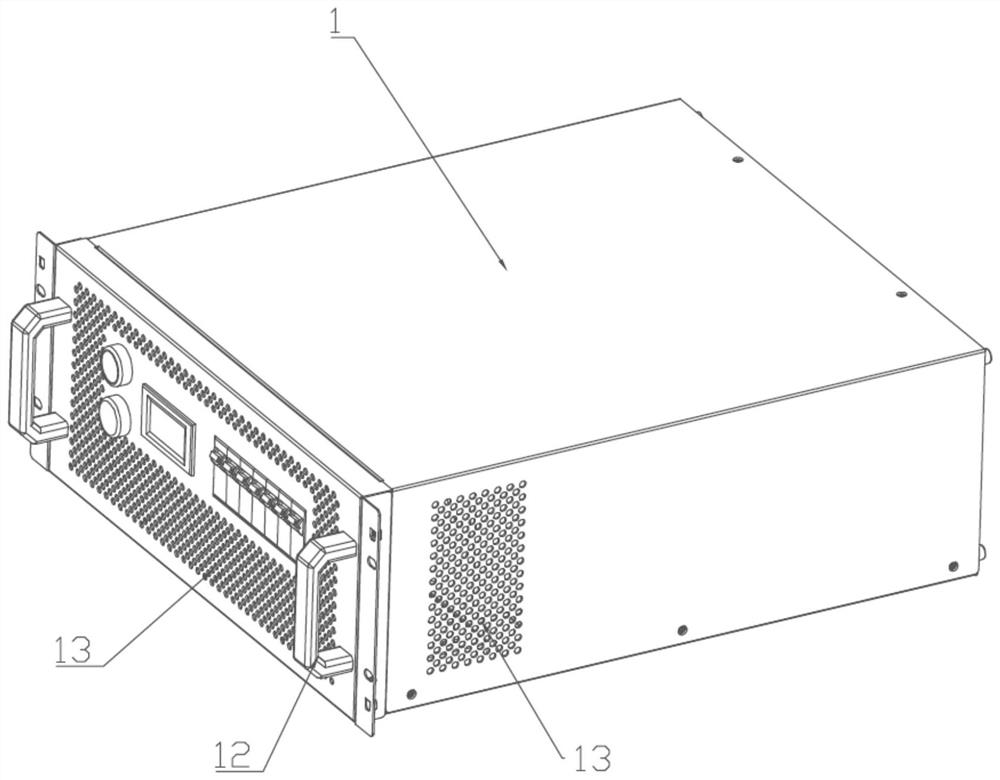

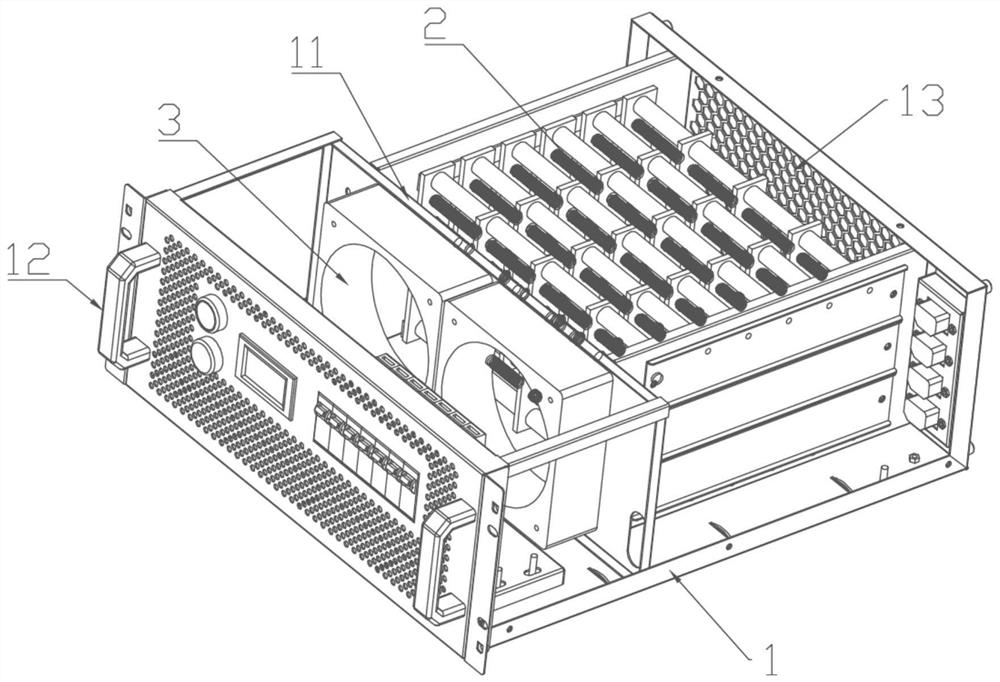

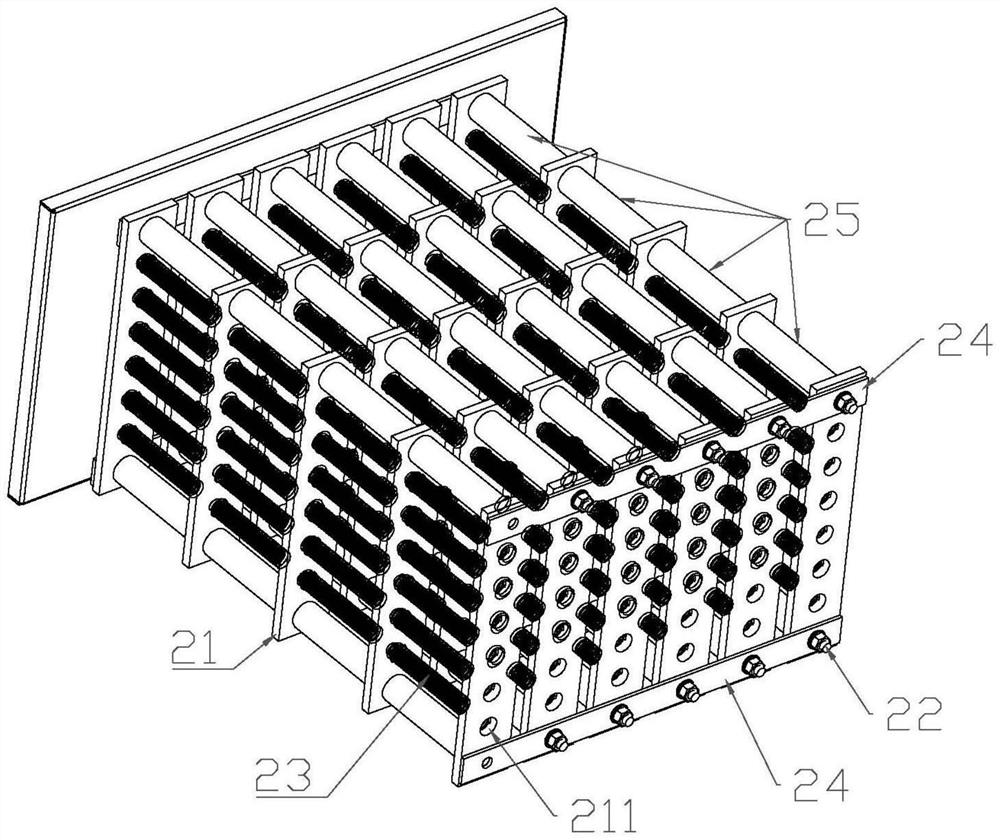

[0025] The high power density rack load of this embodiment, such as Figure 1 to Figure 3 As shown, it includes a box body 1 and a resistance unit 2 arranged in the box body 1, and the resistance unit 2 includes a plurality of parallel resistance rows, image 3 There are six resistor rows, each resistor row includes a plurality of insulating support plates 21, a locking assembly 22 and a plurality of spiral resistance strips 23, and the locking assembly 22 fixes and arranges the plurality of insulating support plates 21 at intervals . Each insulating support plate 21 has a plurality of support holes 211 along its length direction, image 3 Each insulating support plate 21 has six support holes 211, and a plurality of resistance strips 23 respectively pass through the support holes 211 aligned with the plurality of insulating support plates 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com