Generation method and system of power line inspection work order, storage medium and equipment

A power line and work order technology, which is applied in the field of power line inspection work order generation, can solve the problems of wasting management manpower, unable to ensure the rationality and efficiency of inspection task allocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

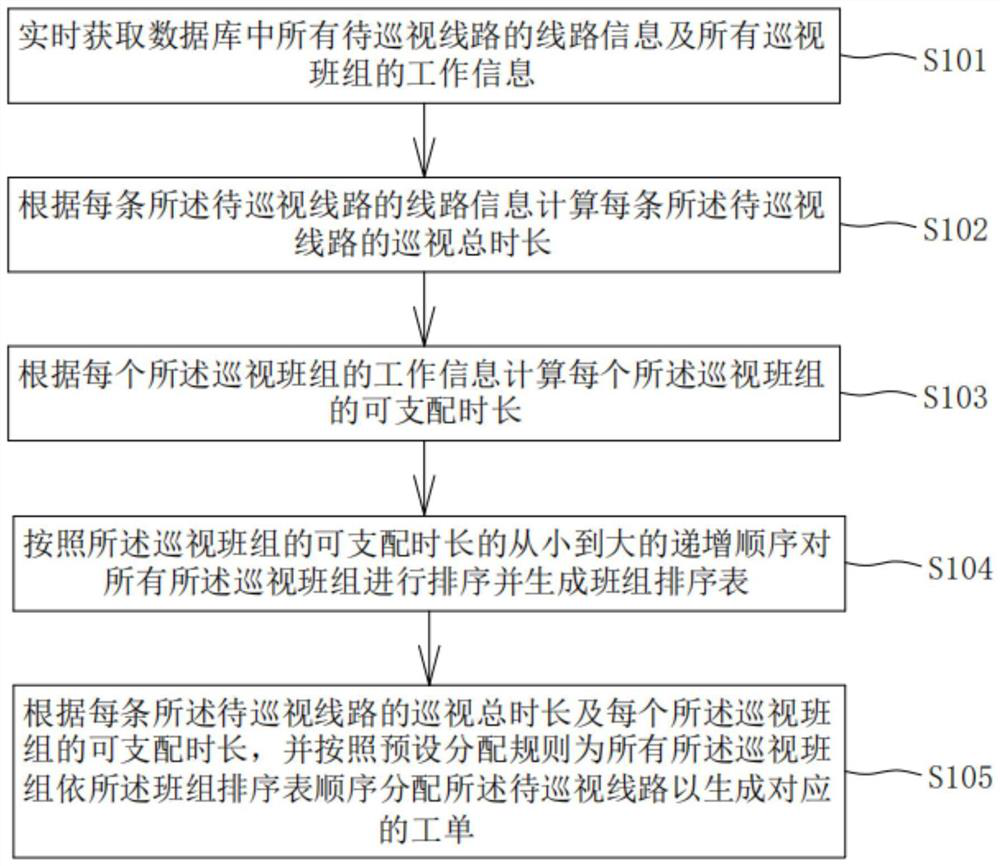

[0053] Such as figure 1 As shown, the embodiment of the present invention provides a method for generating a power line inspection work order, including steps S101-S105.

[0054] S101, obtaining in real time the line information of all lines to be inspected and the work information of all inspection teams in the database.

[0055] S102. Calculate the total patrol duration of each of the routes to be patrolled according to the route information of each route to be patrolled.

[0056] S103. Calculate the available time of each patrol team according to the work information of each patrol team.

[0057] S104. Sort all the touring teams in ascending order of available time lengths of the touring teams and generate a team sorting table.

[0058] S105, according to the total tour duration of each of the lines to be patrolled and the controllable time of each of the patrol teams, and according to the preset allocation rules, assign the to-be-to-be patrolled teams to all the patrol t...

Embodiment 2

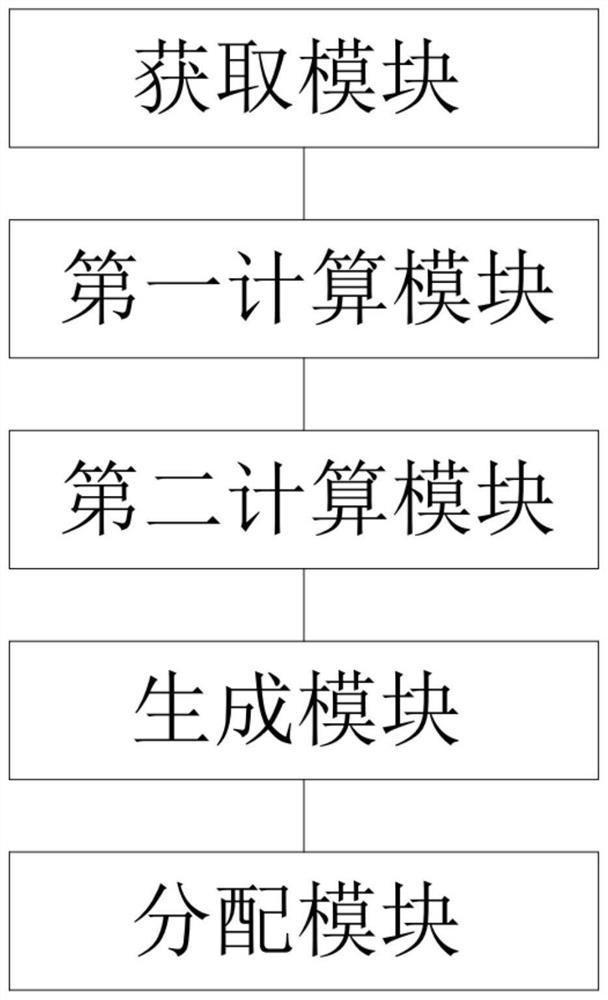

[0116] Please refer to figure 2 , the present embodiment provides a system for generating a power line inspection work order, including:

[0117] Acquisition module: used to obtain the line information of all lines to be inspected in the database and the work information of all inspection teams in real time.

[0118] The first calculation module: used for calculating the total tour duration of each of the lines to be patrolled according to the line information of each of the lines to be patrolled.

[0119] The second calculation module: used for calculating the available time of each patrol team according to the work information of each patrol team.

[0120] Generating module: for sorting all the patrolling teams in ascending order of the controllable duration of the patrolling teams and generating a sorting list of teams.

[0121] Assignment module: used for assigning all the patrolling teams according to the order of the squad sorting table according to the total patrolli...

Embodiment 3

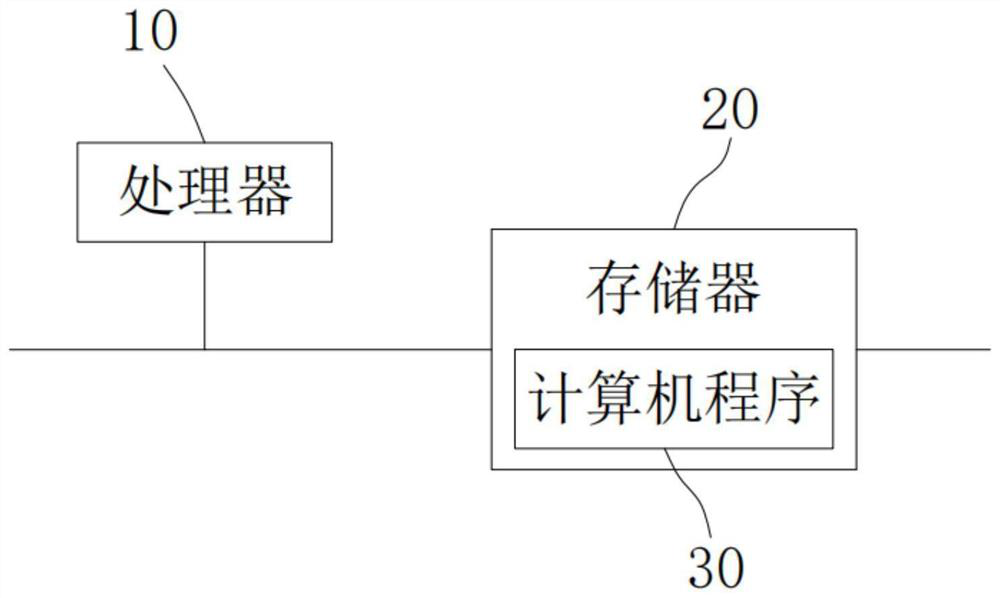

[0163] Please refer to image 3 , the present invention also proposes a generating device for a power line inspection work order, which is shown as a generation device for a power line inspection work order in the third embodiment of the present invention, including a memory 20, a processor 10, and stored in the memory and can be The computer program 30 running on the processor, when the processor 10 executes the computer program 30, realizes the above-mentioned method for generating a power line inspection work order.

[0164] Wherein, the generation device of the power line inspection work order can be specifically a computer, a server, a host computer, etc., and the processor 10 can be a central processing unit (Central Processing Unit, CPU), a controller, a microcontroller in some embodiments. , a microprocessor or other data processing chips, for running program codes stored in the memory 20 or processing data, such as executing access restriction programs and the like.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com