Cultivation method of cordyceps militaris

A cultivation method and technology for Cordyceps militaris are applied in the field of cultivation of Cordyceps militaris, and can solve the problems of low rigidity rate, low yield rate and low content of cordycepin in Cordyceps militaris cultivation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

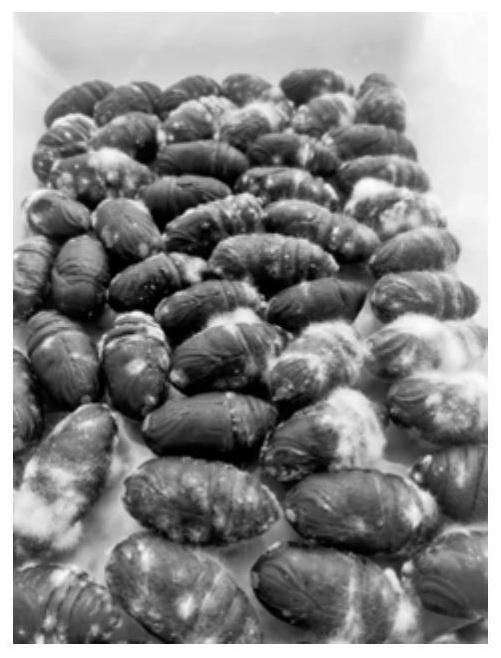

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the cultivation method of a kind of Cordyceps militaris of present embodiment, carry out according to the following steps:

[0028] 1. Add the oily soybean meal hydrolyzate, calcium gluconate mother solution and vitamin C mother solution into deionized water, after fully stirring, sterilize and cool to room temperature to obtain a sterilized liquid medium; under sterile conditions, the pupa The mother species of Cordyceps is inoculated in the sterilized liquid medium, and the inoculation amount is 5-10 pieces / 0.5cm 3 , and cultured for 5-7 days at a temperature of 18-22°C and a rotational speed of 140-160r / min to obtain liquid production seeds;

[0029] 2. Under sterile conditions, inoculate the liquid production seeds on the surface of live silkworm chrysalis pupa skin, the inoculation amount is 0.4-0.6mL / one silkworm chrysalis; incubate the live silkworm chrysalis after inoculation at a temperature of 16-20°C in the dark After 20-30 days, the...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the hydrolyzate of oily sage soybean meal, calcium gluconate mother liquor and vitamin C mother liquor are added to deionized water, and after fully stirring, extinguish at 121 ° C. Bacteria for 30 minutes, cooled to room temperature to obtain a sterilized liquid culture medium, the volume ratio of the oily sage soybean meal hydrolyzate, calcium gluconate mother liquor and vitamin C mother liquor to deionized water is 10mL: 2mL: 1.5mL: 1000mL.

[0035] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0036]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the hydrolyzed liquid of oily soybean meal is prepared according to the following steps: adding oily soybean meal to a sulfuric acid solution with a concentration of 1.2%, and the solid-to-liquid ratio is 1:8, then reacted at 123°C for 2 hours, and after solid-liquid separation, the initial hydrolyzate was obtained; the initial hydrolyzate was neutralized by calcium carbonate emulsion to pH 3.5, and then decolorized by 1.0% activated carbon for 30 minutes, to obtain Oily Sha soybean meal hydrolyzate, the mass fraction of soluble solids in the oily sand soybean meal hydrolyzate is 10.0%, the mass fraction of total reducing sugar is 8.0%; the total reducing sugar is composed of 80% glucose, 15% arabinose and 5% xylose .

[0037] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Upper caliber | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com