Surface roughness evaluation method based on Hoyer coefficient of processed surface image

A technology of surface roughness and surface processing, which is applied in the field of surface roughness evaluation based on the Hoyer coefficient of processed surface images, can solve the problem of less involvement of feature extraction methods, and achieve the effect of fast evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

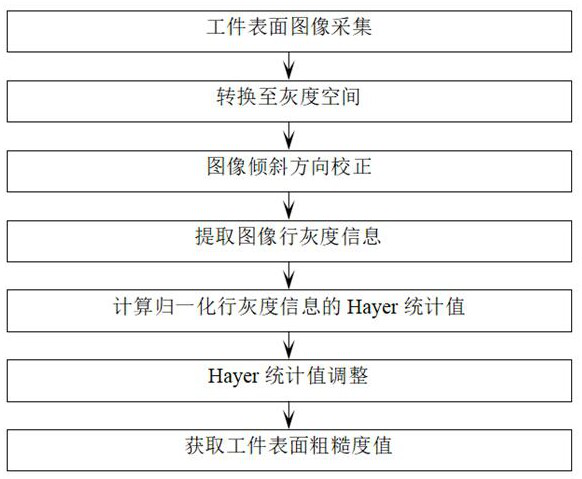

[0052] Embodiment 1: through a series of nodular cast iron 500-7 cutting experiments are used to carry out the verification of the method, its flow chart is as follows figure 1 shown, including the following steps:

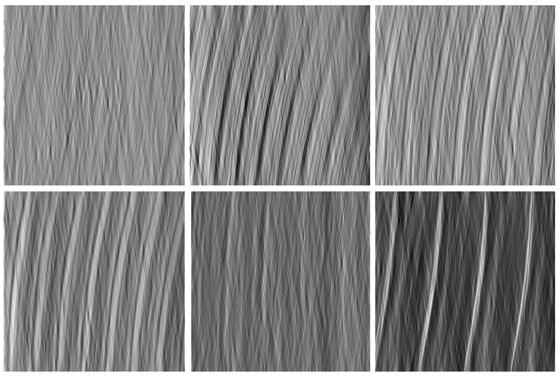

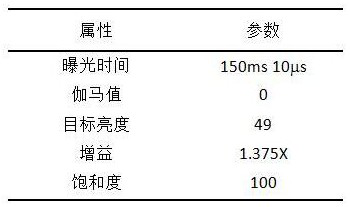

[0053] S1: Three different machine tools (VMC650E / 850E, XK63100, NBH800) were used for cutting experiments. The size of the workpiece is fixed at 200mm x 140mm x 100mm. The technological parameters of the three machine tools during the experiment are as attached figure 2 Shown are: type VMC650E / 850E machine tool, the milling method is up-cut milling, the tool is a disc milling cutter, the feed speed is 200mm / min, the spindle speed is 960rpm, and the depth of cut is 0.5mm; type XK63100 machine tool, the milling method is down Milling, the tool is a disc milling cutter, the feed rate is 500mm / min, the spindle speed is 450rpm, and the depth of cut is 4mm; type NBH800 machine tool, the milling method is down milling, the tool is a disc milling cutter, the feed rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com