Single-acting arc extinguish chamber and static end contact structure thereof

A moving arc contact and arc extinguishing chamber technology, which is applied to electrical components, electrical switches, circuits, etc., to improve the opening efficiency, increase the insulation distance, and reduce the probability of heavy breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

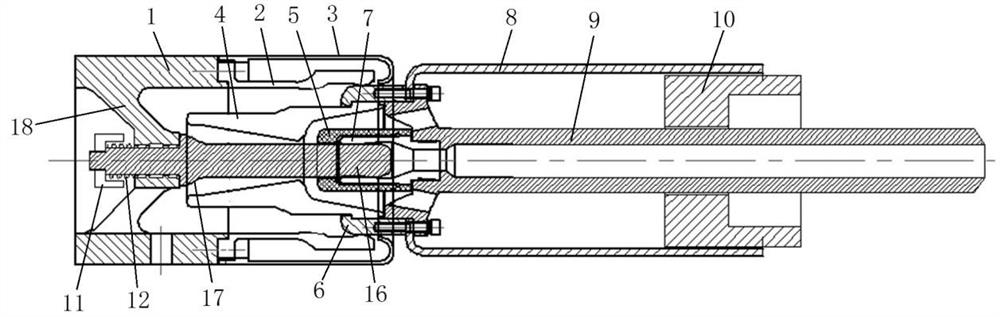

[0059] like Figure 1 to Figure 3 As shown, the structure of the arc extinguishing chamber provided in this embodiment is basically the same as that of the existing compressed gas type arc extinguishing chamber. Here, the structure of the movable end contact and the static end contact inside the arc extinguishing chamber are mainly introduced.

[0060] For the convenience of expression, the front and rear directions here define the linear action direction of the moving end contact structure when the opening and closing operation is performed. The rear movement communicates with the static end contact structure for closing operation, and the moving end contact structure moves forward to separate from the static end contact structure for opening operation.

[0061] The structure of the moving end contact mainly includes the nozzle 4, the auxiliary nozzle 5, the moving main contact 6, the moving arc contact 7, the pressure cylinder 8, the pull rod 9, and the moving conductive sup...

specific Embodiment 2

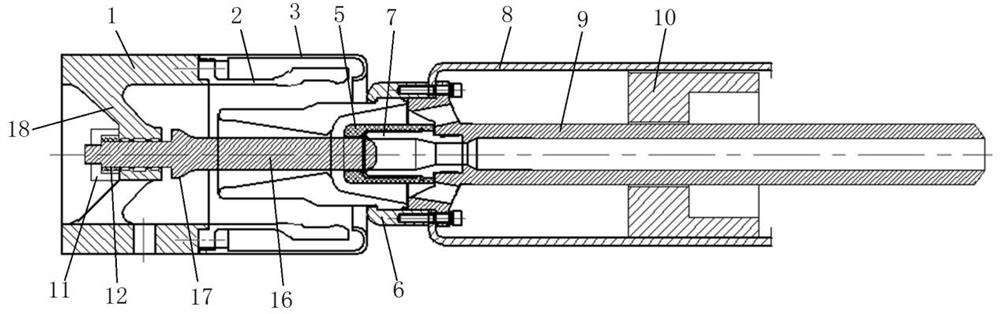

[0075] It differs from Embodiment 1 mainly in that in Embodiment 1, the front end of the static arc contact at the closing limit position is flush with the front end of the static shield. In this embodiment, the front end of the static arc contact at the closing limit position is located in the static shield.

[0076] Of course, in other embodiments, the front end of the static arcing contact can also protrude from the static shield according to actual needs, for example, in the case of high voltage levels. It should be noted that even if the front end of the static arcing contact protrudes from the static shielding cover, at the same voltage level, compared with the relatively fixed arrangement of the static arcing contact and the static main contact, the present invention provides, The motion assembly method of the static arc contact can also effectively reduce the forward protrusion of the static arc contact, thereby also optimizing the electric field between the fractures....

specific Embodiment 3

[0078] The main difference between it and Embodiment 1 is: in Embodiment 1, the stopper is an adjustable nut, which can be continuously adjusted along the front and rear directions. In this embodiment, the stopper is a stopper sleeve, and positioning holes are arranged on the stopper sleeve, and a plurality of through holes are arranged at intervals along the front and back direction on the static arc contact, and the rear stopper is adjusted according to actual needs. The position of the sleeve is fixed, and then the positioning pin is inserted, so that the stop sleeve can be positioned and arranged at the corresponding position, which belongs to a step-by-step adjustment.

[0079] Of course, the stopper and the static arc contact can also be directly welded and fixedly assembled together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com