Cam welding machine

A welding machine and welding mechanism technology, applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of large energy consumption, small application range, and poor structure, so as to reduce the power consumption of equipment and the application range Wide, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

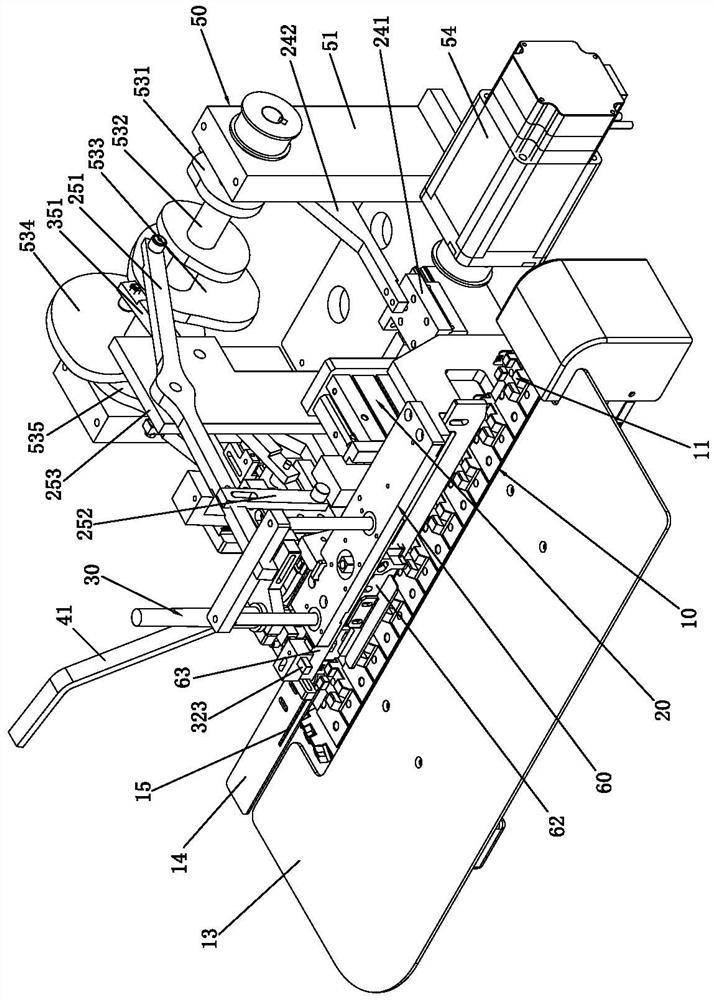

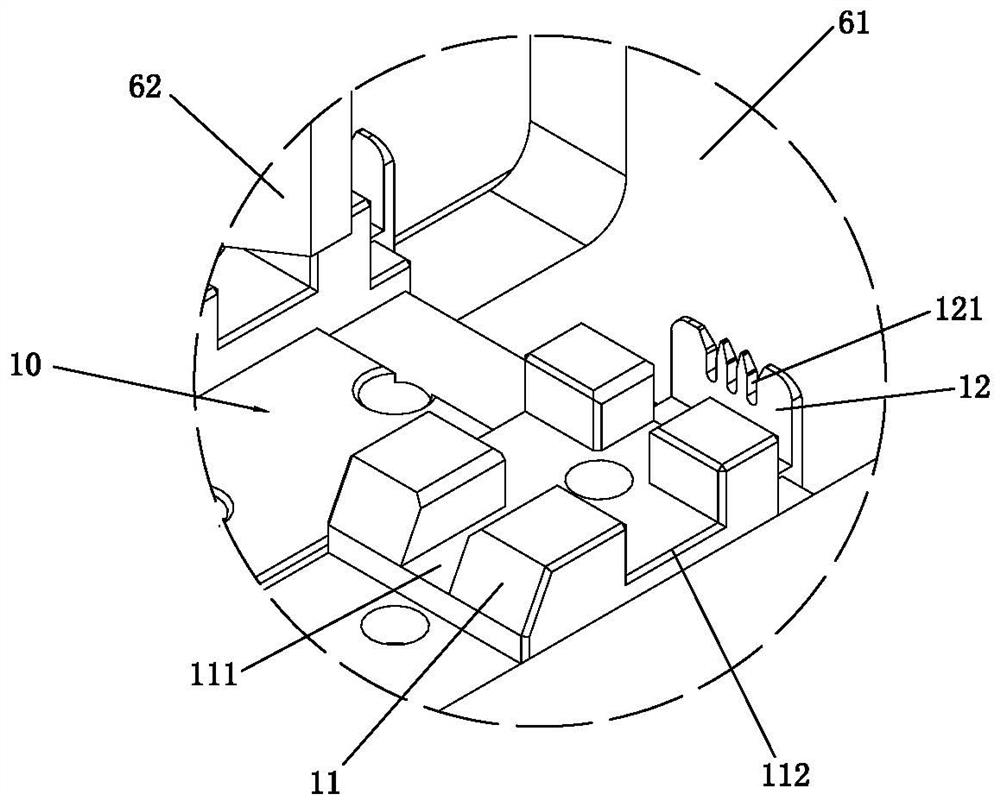

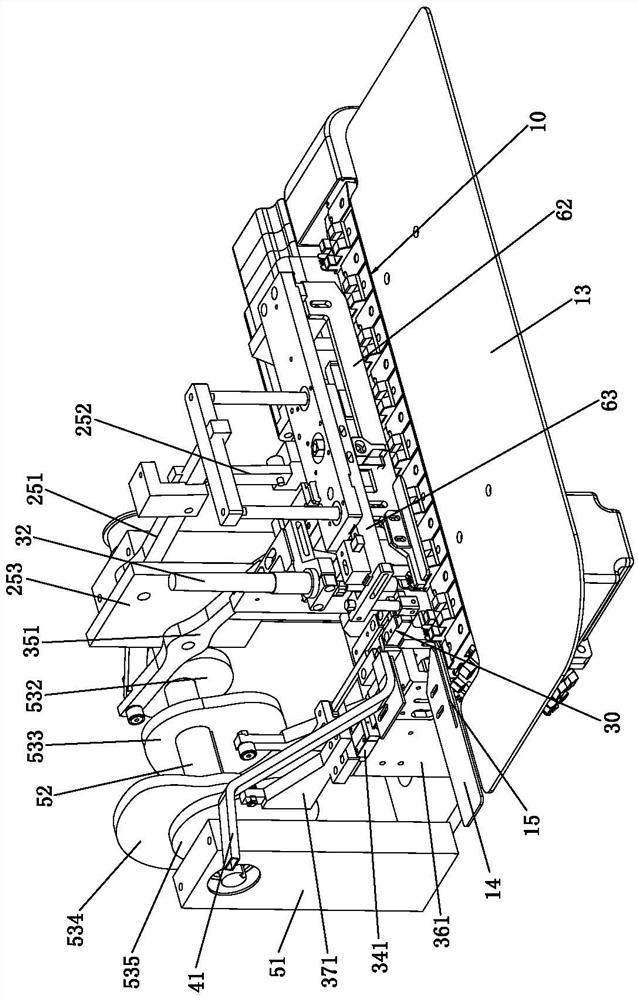

[0067] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the embodiment of the present invention.

[0068] A cam welding machine includes a conveying mechanism 10, a peeling mechanism 20, a welding mechanism 30, a joint feeding mechanism and a cam transmission mechanism 50; wherein:

[0069] The peeling mechanism 20, the welding mechanism 30 and the joint feeding mechanism are sequentially arranged on the rear side of the conveying mechanism 10 from left to right, and the cam transmission mechanism 50 is arranged behind the peeling mechanism 20 and the welding mechanism 30. The cam transmission mechanism 50 includes a seat body 51, a rotating shaft 52, a cam module and a driving device 54. The rotating shaft 52 extends left and right and is rotatably arranged on the seat body 51. The driving device 54 is drivingly connected to one end of the rotating shaft 52. The driving device 54 is connected to the rotating shaft 52 through a pulley, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com