Package stripping equipment

A stripping equipment and component installation technology, applied in the direction of electrical components, circuits, connections, etc., can solve the problems of poor peeling effect of the wallpaper knife, easy damage to the internal protection tube, and unsatisfactory cutting effect, etc., to achieve convenient and fast handling, structure Compact and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

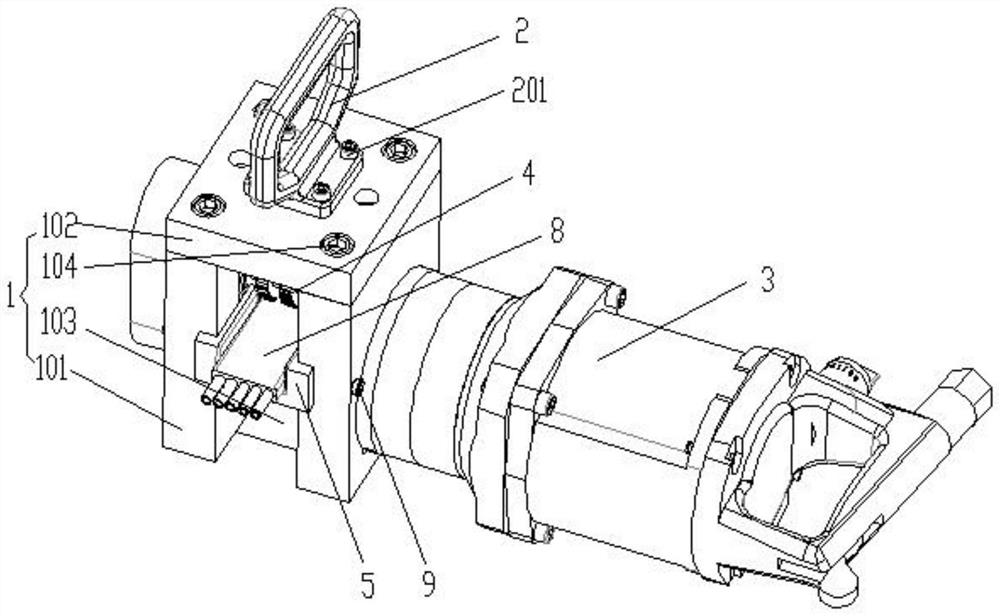

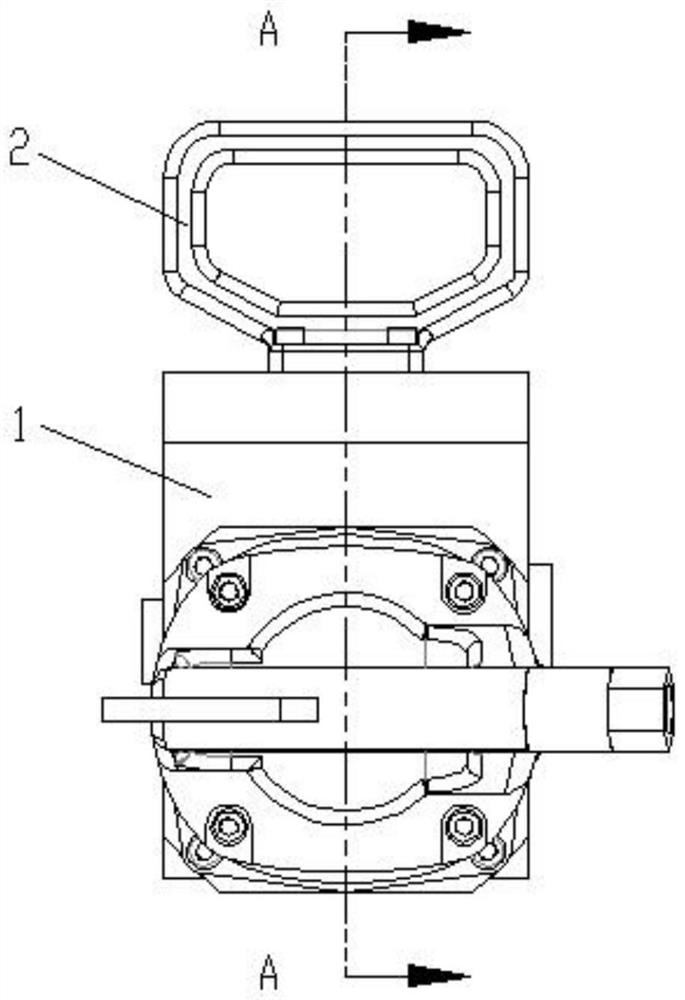

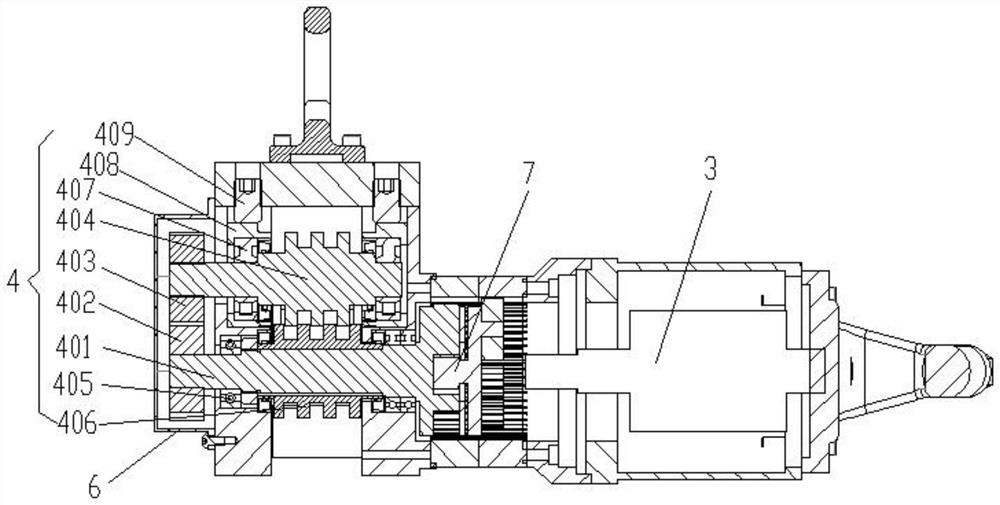

[0033] like Figure 1-3 As shown, a packaging stripping device includes a support frame 1, a driving air motor 3, an extrusion assembly 4 and a feeding pallet 5, the extrusion assembly 4 is installed inside the support frame 1, and the output end of the drive air motor 3 is connected to the The extrusion assembly 4 is connected by transmission and drives the extrusion assembly 4 to complete the cable extrusion operation; the feeding end of the support frame 1 is connected to the feeding pallet 5, and the feeding pallet 5 is designed with U-shaped grooves, U-shaped grooves The width inside matches the specification of the cable 8 to be processed.

[0034] Specifically, the support frame 1 includes two legs 101 and an upper support plate 102, and the upper support plate 102 overlaps the top surface of the legs 101 and is connected by first connecting bolts 104 to form a U-shaped frame. The bottom of the two parallel legs 101 is connected with a lower connecting column 103 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com