Mechanical taking and placing device with high intelligent degree

A technology of intelligent level and pick-and-place device, which is applied in the direction of program-controlled manipulators, manipulators, chucks, etc., can solve the problems of weak automation ability, inability to cooperate with production equipment, and low automation level, so as to reduce high costs and enhance equipment automation The ability to operate, the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

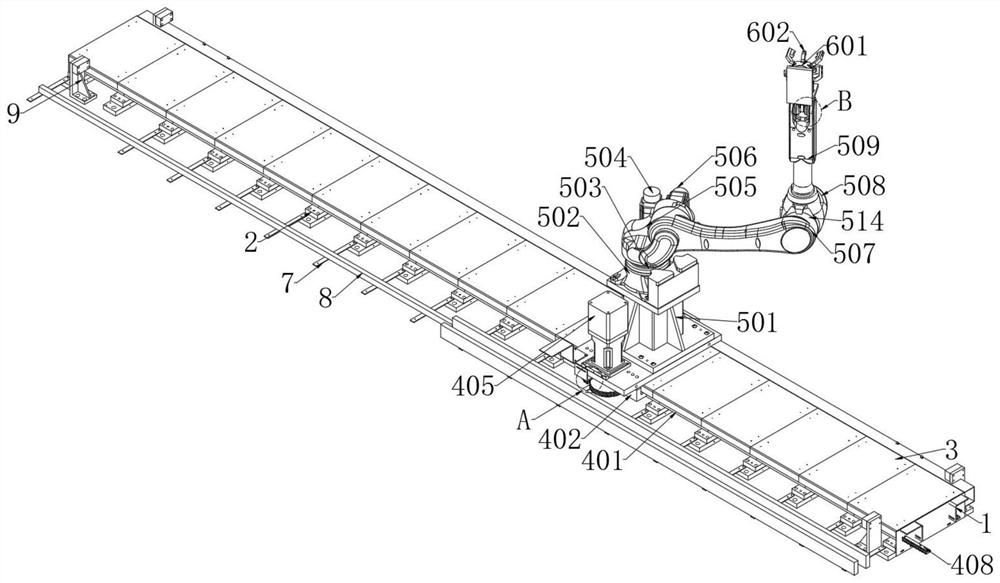

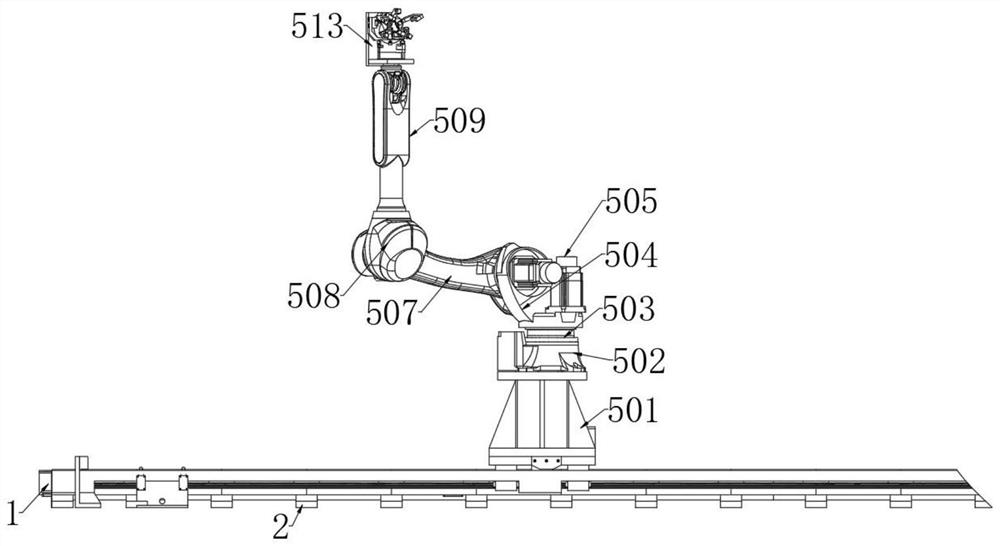

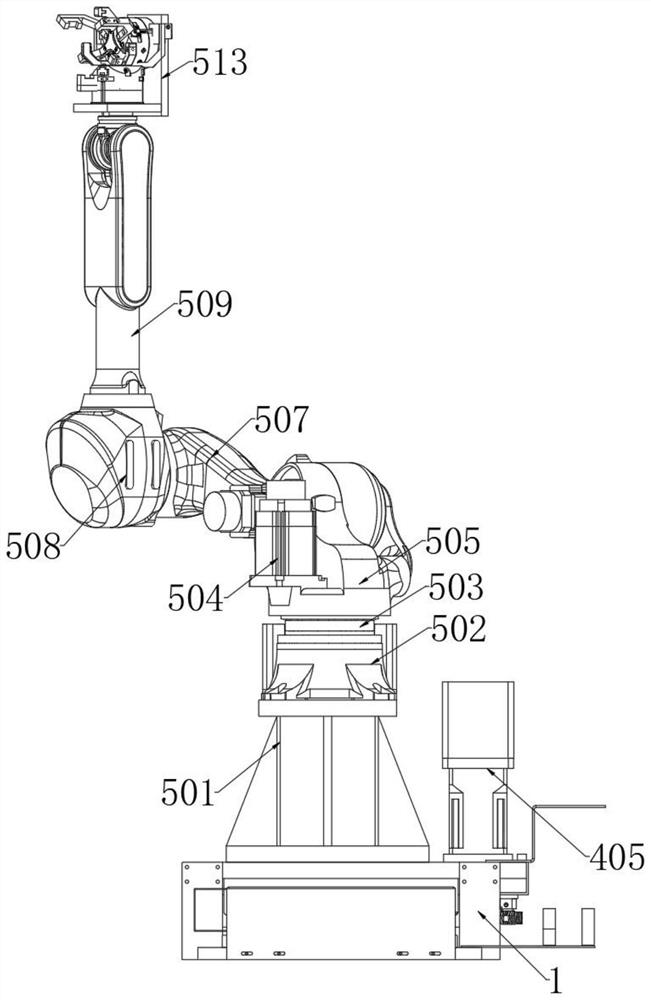

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] Such as Figure 1-7 As shown, the present invention provides a mechanical pick-and-place device with a high degree of intelligence, which includes two support plates 1, and a mechanical transmission mechanism, a material conveying mechanism and a grabbing mechanism are respectively fixedly installed between the tops of the two support plates 1 .

[0031] Such as Figure 1-7 As shown: two or more connecting bases 2 are welded between the bottoms of the two support plates 1, and a movable top plate 3 is fixedly installed between the tops of the two support plates 1;

[0032]The material conveying mechanism includes an L-shaped frame 402 and a transfer base 403. Track slides 401 are provided on both sides of the moving top plate 3. The two L-shaped frames 402 are fixed on the bottom of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com