Drainage groove for road construction

A technology for road construction and drainage tanks, which is applied in the direction of roads, roads, and sewage discharge, etc. It can solve problems such as inconvenient construction, inability to be well discharged, delaying construction progress and construction quality, and achieves the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

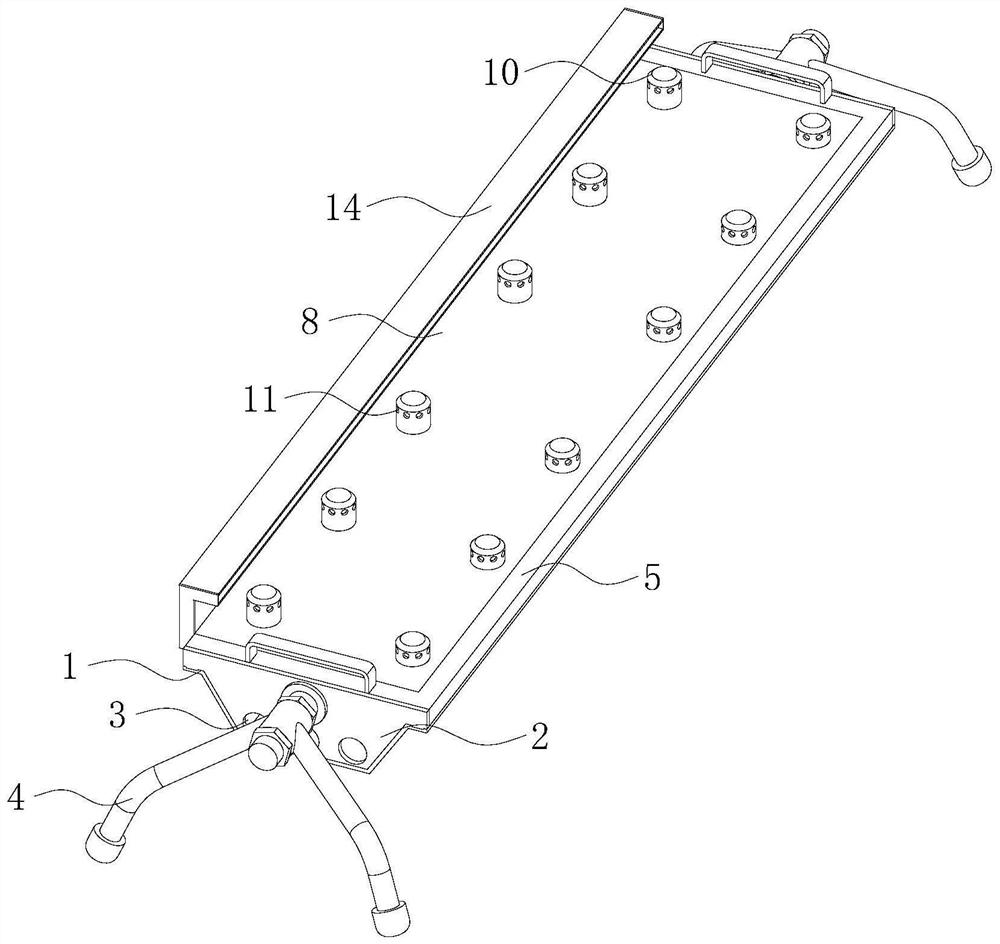

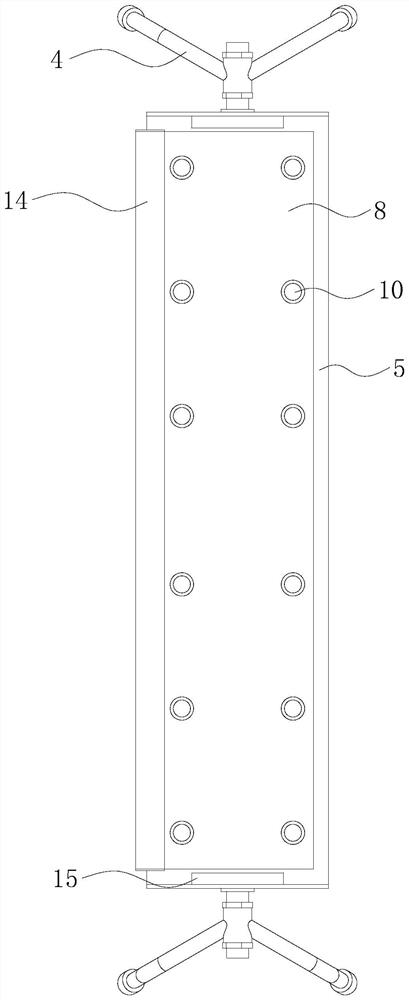

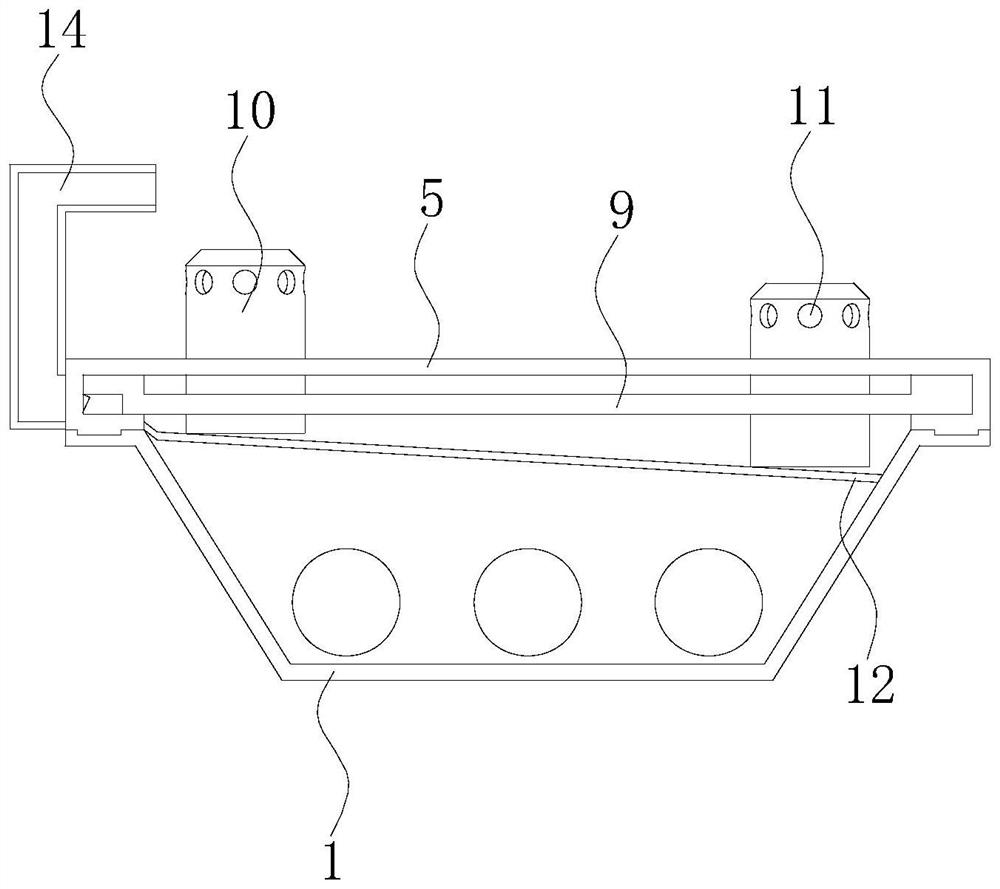

[0024] Such as Figure 1-7 As shown, a drainage channel for road construction includes a tank body 1, the front and rear ends of the tank body 1 are fixedly equipped with sealing plates 2, two sealing plates 2 seal the front and rear ends of the tank body 1, and the two sealing plates 2 The bottom of the tank is provided with three water holes 3, the sealing plate 2 provided on the tank body 1 can connect the two sets of devices together, the water holes 3 can communicate with the waterway, and the front and rear ends of the sealing plate 2 are provided with brackets 4, The sealing plate 2 and the support 4 are fixed by nuts, the sealing plate 2 can rotate relative to the support 4, the upper end of the support 4 is provided with a sleeve, and the sleeve and the sealing plate 2 are connected by threaded rods, and the two nuts are distributed in the sleeve On the front and rear sides of the cylinder, the nuts are sleeved on the threaded rods to fix the sleeve. The bracket 4 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com