Transformer oil pump sealing test device and test method

A sealing test and transformer oil technology, applied in the field of transformer oil pumps, can solve the problems of affecting the sealing test results of oil pumps, heating and expansion, and not easy to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

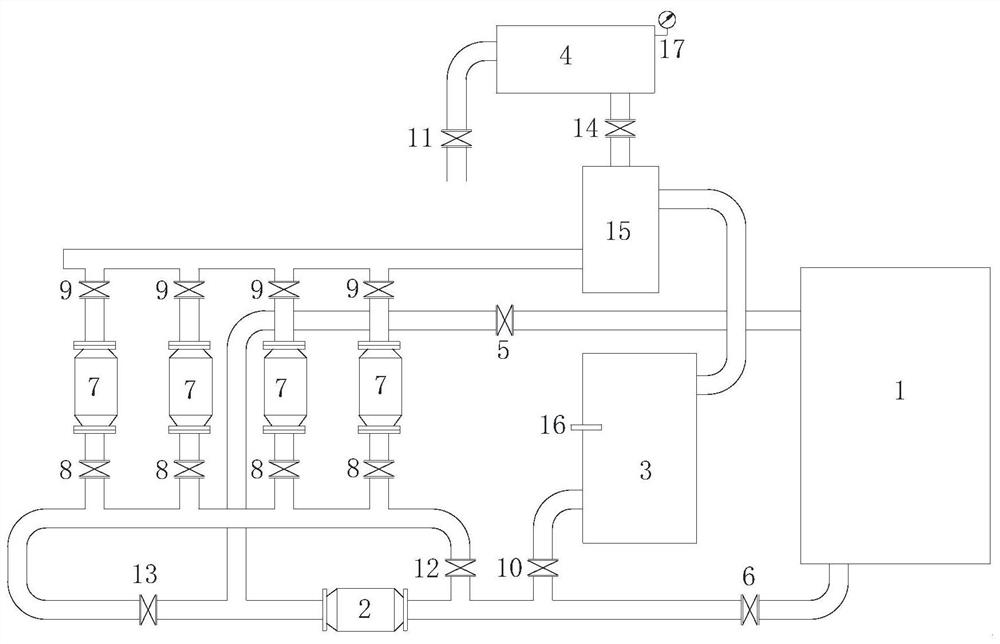

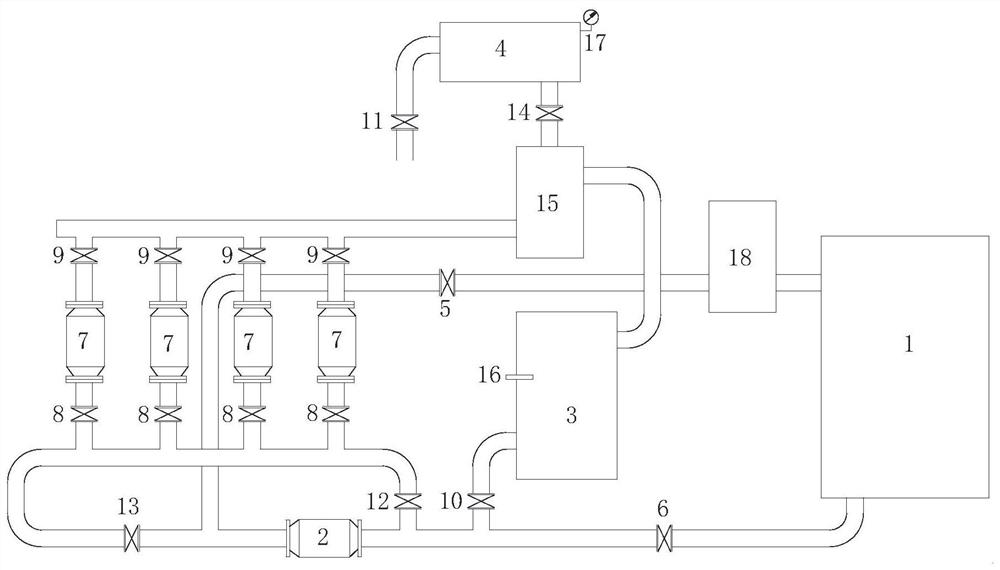

[0023] In this embodiment, the first filter device 15 is arranged on the oil outlet pipeline; the third electric valve 14 is arranged between the first filter device 15 and the fuel tank 4 . The first filtering device 15 is used to filter the transformer oil during the test, to prevent the oil pump 7 to be tested from being polluted by unclean transformer oil, to keep the inside of the oil pump 7 to be tested clean all the time, and to ensure the subsequent normal use of the oil pump 7 .

[0024]In this embodiment, the heating tank 3 is provided with a temperature sensor 16; the temperature sensor 16 is electrically connected to the control system for real-time detection of the temperature of the transformer oil in the heating tank 3 and sent to the control system to ensure that the transformer oil is always Maintain the specified temperature value. Further, the temperature sensor 16 is a PT100 temperature sensor. The PT100 temperature sensor is easy to make, simple to use, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com