Centralized processing equipment for medical equipment

A medical equipment and centralized processing technology, applied in grain processing, chemical instruments and methods, liquid injection devices, etc., can solve the problems of waste of manpower, no cooling function, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

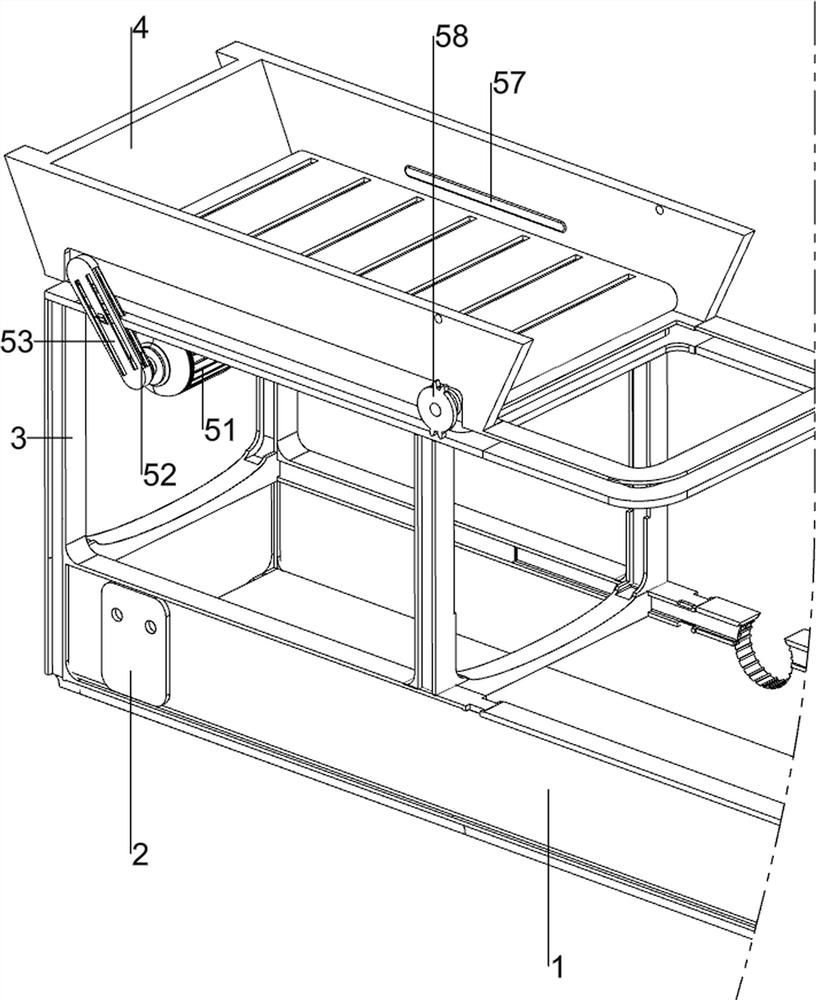

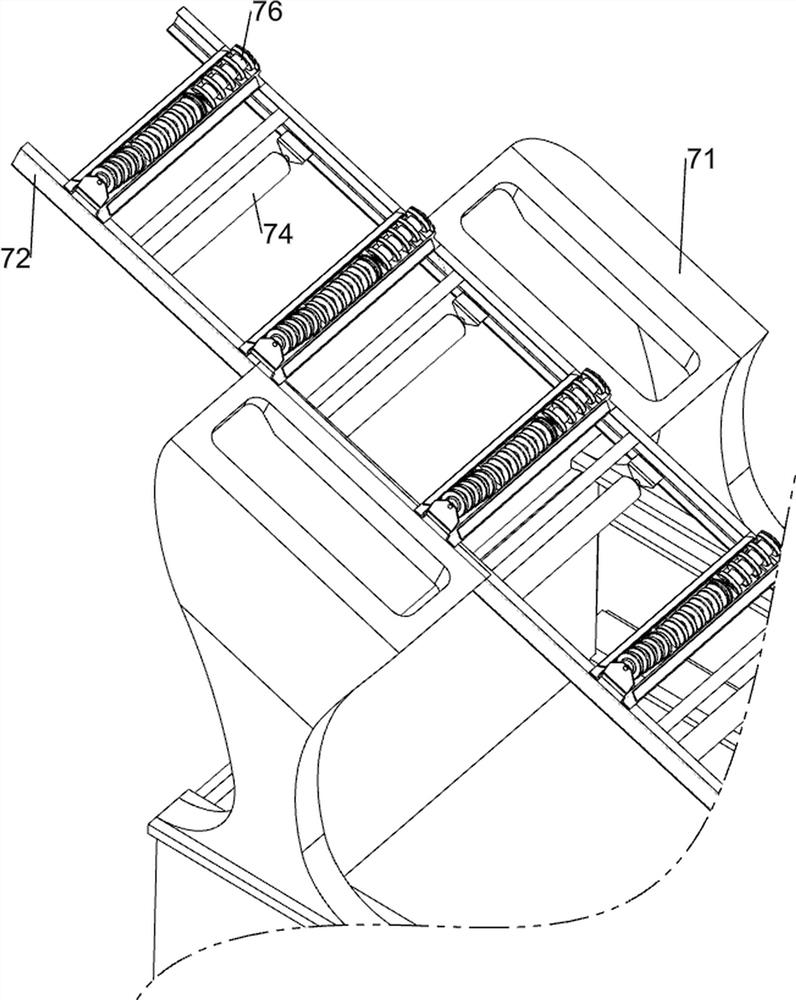

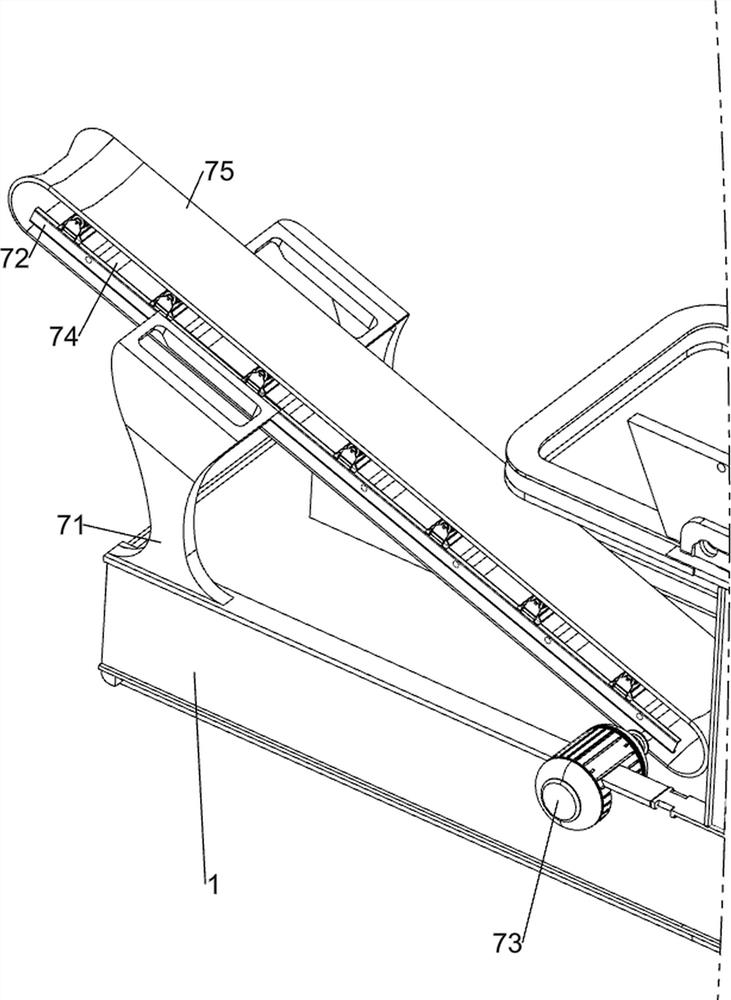

[0036] A centralized processing equipment for medical medical equipment, such as Figure 1-Figure 15 As shown, it includes a partition 1, a control panel 2, a liquid level sensor 21, a first support frame 3, a placement frame 4, a crusher 41, a material delivery mechanism 5, a crushing mechanism 6, a material delivery mechanism 7 and a cooling mechanism 8. A control panel 2 is provided on the left side of the front side of the partition 1, a liquid level sensor 21 is provided on the left rear side of the inner bottom of the partition 1, a first support frame 3 is provided on the left side of the top of the partition 1, and the first support frame 3 There is a placement frame 4 on the top, a material transport mechanism 5 is arranged on the placement frame 4, a crushing mechanism 6 is arranged on the upper right side of the first support frame 3, and a crushing device for crushing medical equipment is installed on the crushing mechanism 6 41. A feeding mechanism 7 is provided o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap