Modularized pipeline installation method

A pipeline installation and modularization technology, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, passing elements, etc., and can solve the problem that the support ring does not fit pipes of different specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

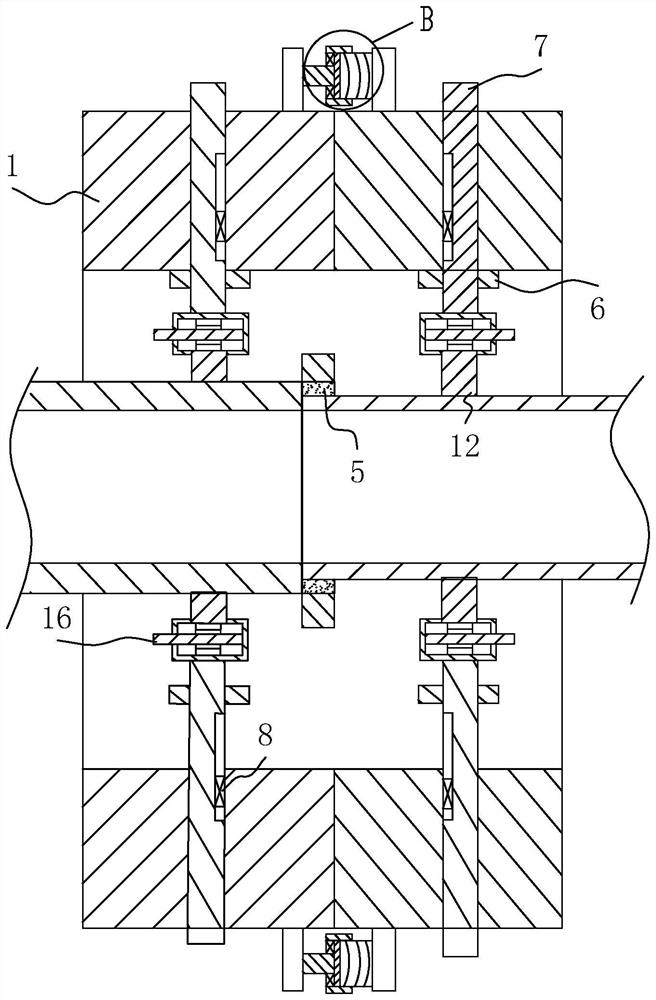

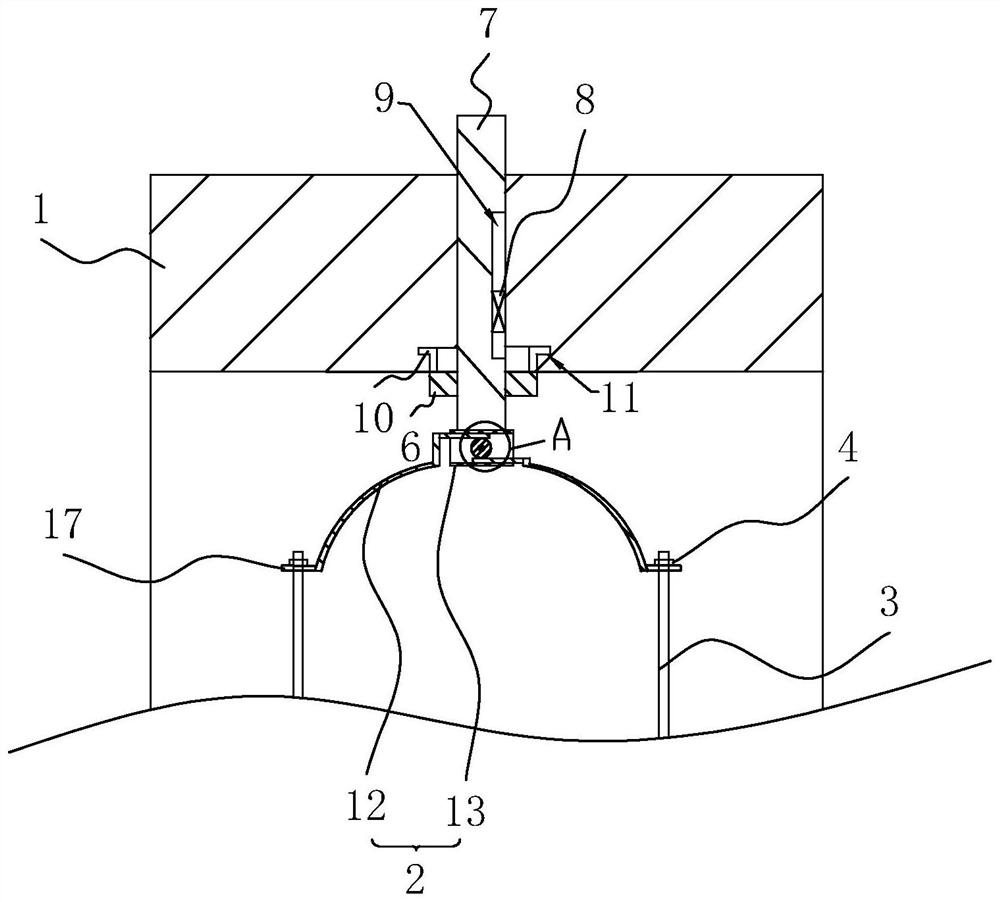

[0039] The following is attached Figure 1-5 The application is described in further detail.

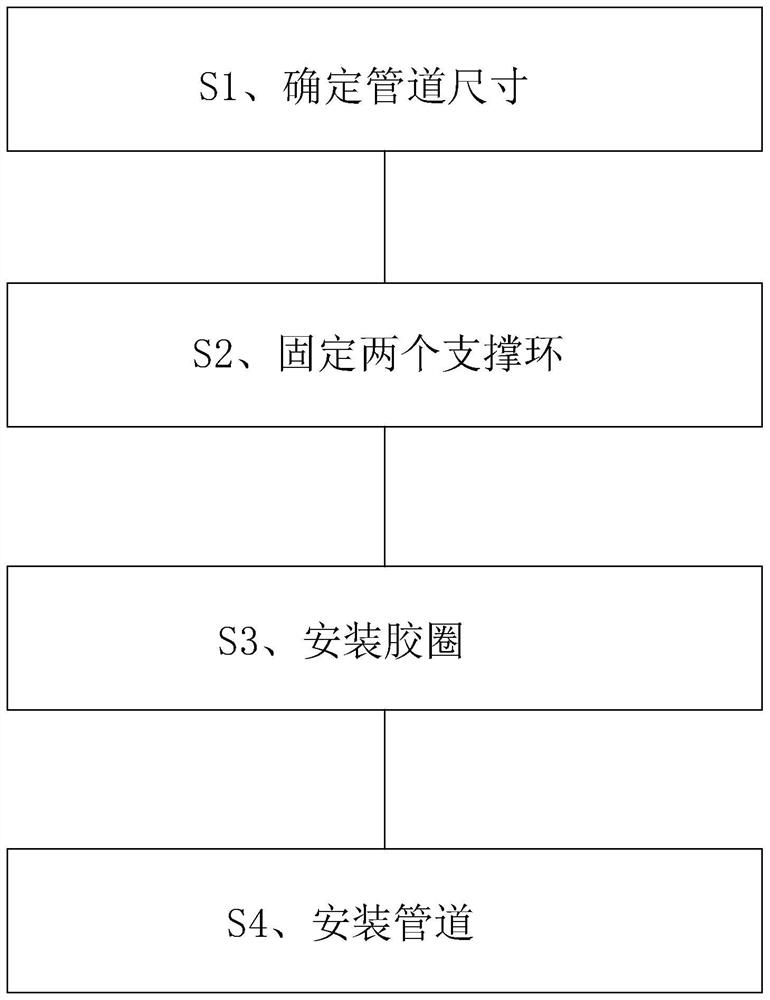

[0040] The embodiment of the present application discloses a modular pipeline installation method. refer to figure 1 and figure 2 , a modular pipeline installation method includes the following steps:

[0041] S1. Determine the size of the pipe, adjust the position of the support ring 2 in the mold frame 1 according to the size of the pipe, and adjust the opening size of the support ring 2 at the same time to ensure that the support ring 2 is compatible with the pipe;

[0042] refer to figure 2 and image 3The support ring 2 includes two ring arms 12 and a support seat 13, the two ring arms 12 are arranged symmetrically with respect to the vertical symmetry plane of the support seat 13, the ring arms 12 are arranged in an arc shape, the support seat 13 is provided with a cavity and Both ends are openings, the ring arm 12 is slidably connected in the cavity, and the support se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com