Cabin penetrating pipeline structure

A technology for pipelines and cabins, applied in the direction of pipes, pipes/pipe joints/fittings, flange connections, etc., can solve the problems of easy aging of welds, difficult post-maintenance, and leakage of welds, so as to avoid corrosion problems and improve The effect of maintaining and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

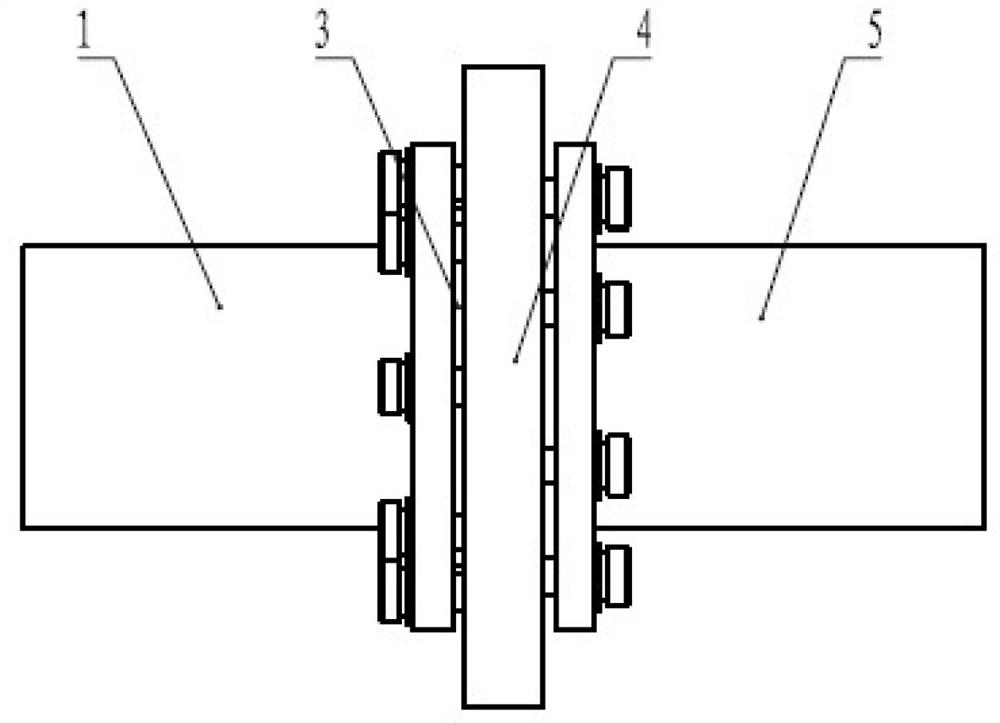

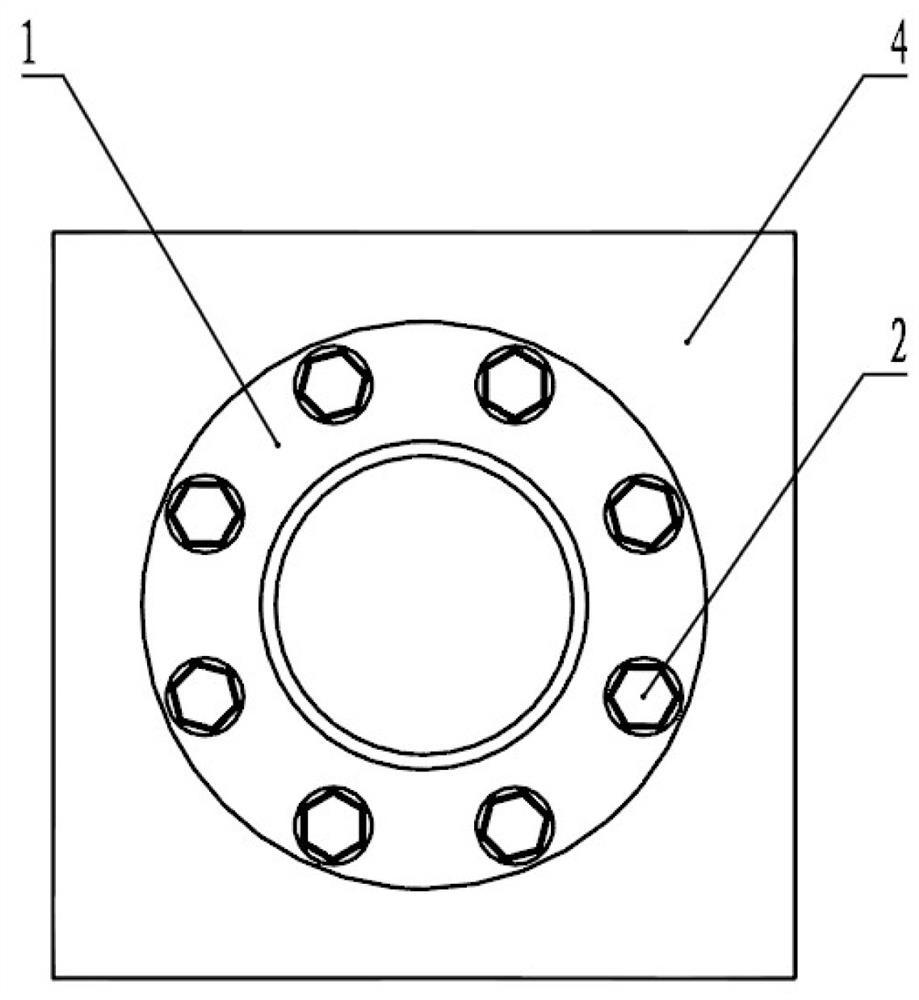

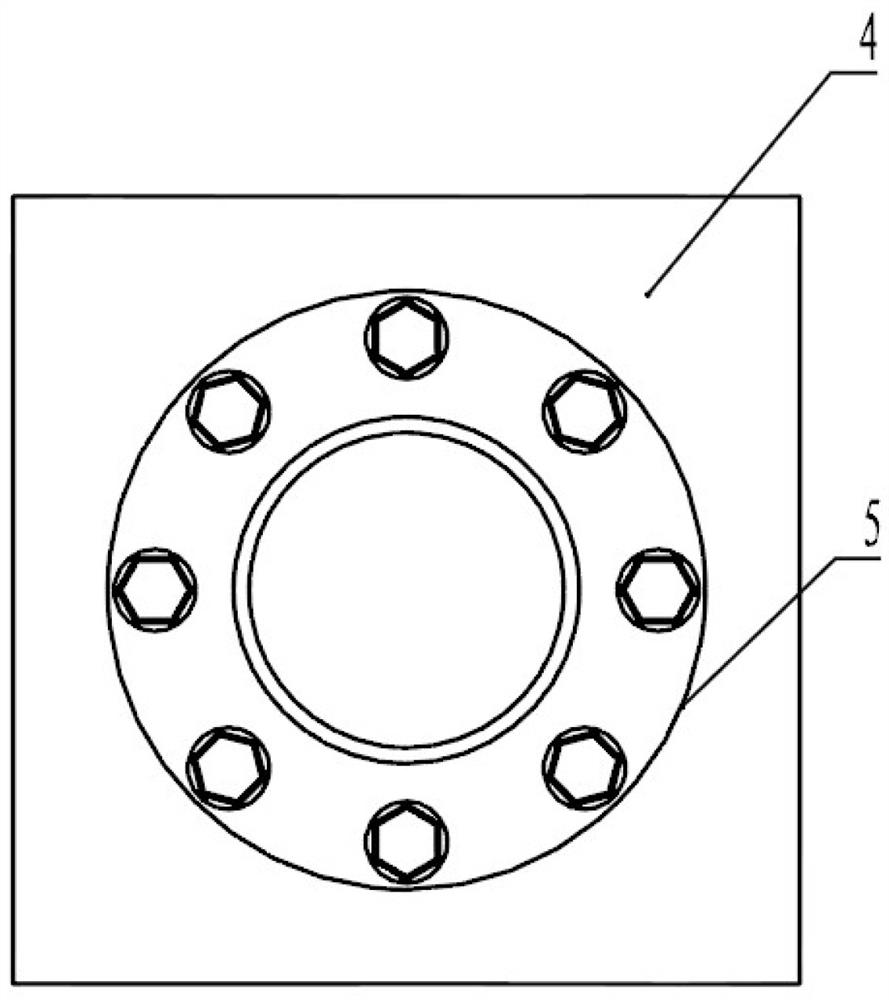

[0015] refer to Figures 1 to 5 As shown, a pipeline structure disclosed by the present invention includes a connecting plate 4 and A pipeline 1 and B pipeline 5 respectively connected to the connecting plate 4 through fastening bolts 2. The connecting plate 4 is selected to be the same as that of the bulkhead. The material is formed integrally with the bulkhead by welding, and the number of fastening bolts 2 can be adjusted according to the effect of fastening and sealing. The connecting plate 4 is provided with a circular hole for pipelines to pass through. A sealing ring 3 with an I-shaped cross section is installed in the hole. The I-shaped sealing ring 3 is installed at the position where the connecting plate 4 passes through. The I-shaped sealing ring 3 is integrally formed with soft rubber and other materials. The size of the opening an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com