Extrusion moulding method of pure platinum cupped utensil

A technology of extrusion forming and cupping, which is applied in the field of metal plastic forming, can solve the problems of reducing the overall corrosion resistance of cup-shaped parts, unfavorable use of cup-shaped parts, and large differences in plate structure, so as to facilitate the organization of continuous production, The effect of shortening the production cycle and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

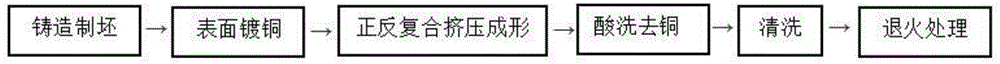

[0030] Such as figure 1 As shown, this embodiment includes the following steps:

[0031] 1. Billet making, the pure platinum billet with hollow structure is obtained through casting process, and then annealed.

[0032] 2. The surface is copper-plated, and a layer of 10μm copper coating is plated on the surface of the hollow blank by electroplating. The specific parameters related to the electroplating process are: main salt concentration 60g / L, current density 20A / dm 2 , the temperature of the electroplating solution is 30°C, and the electroplating time is 20min.

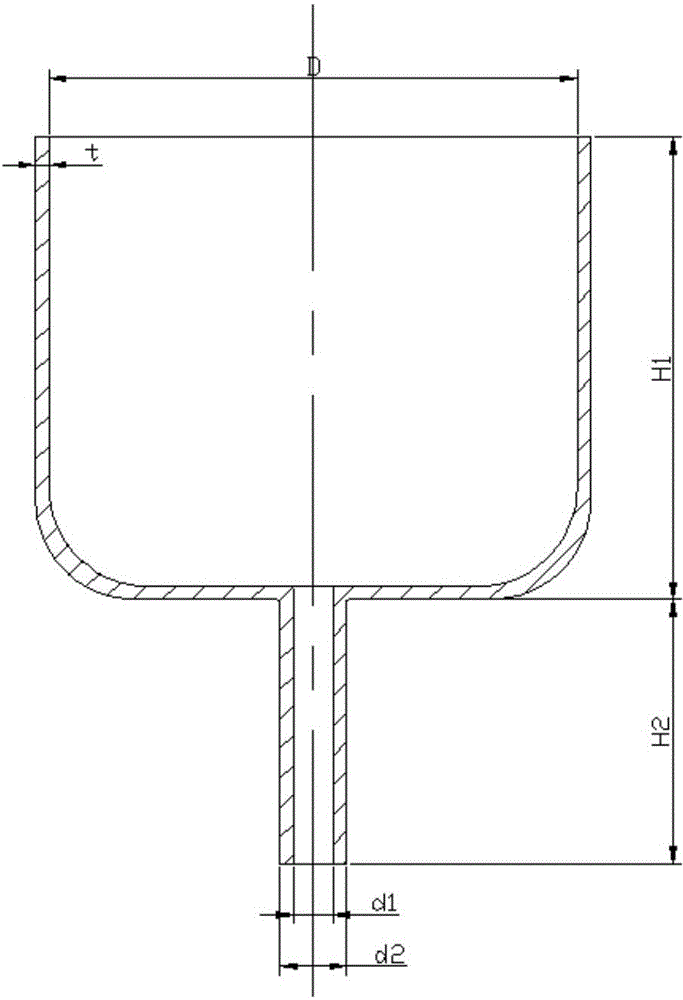

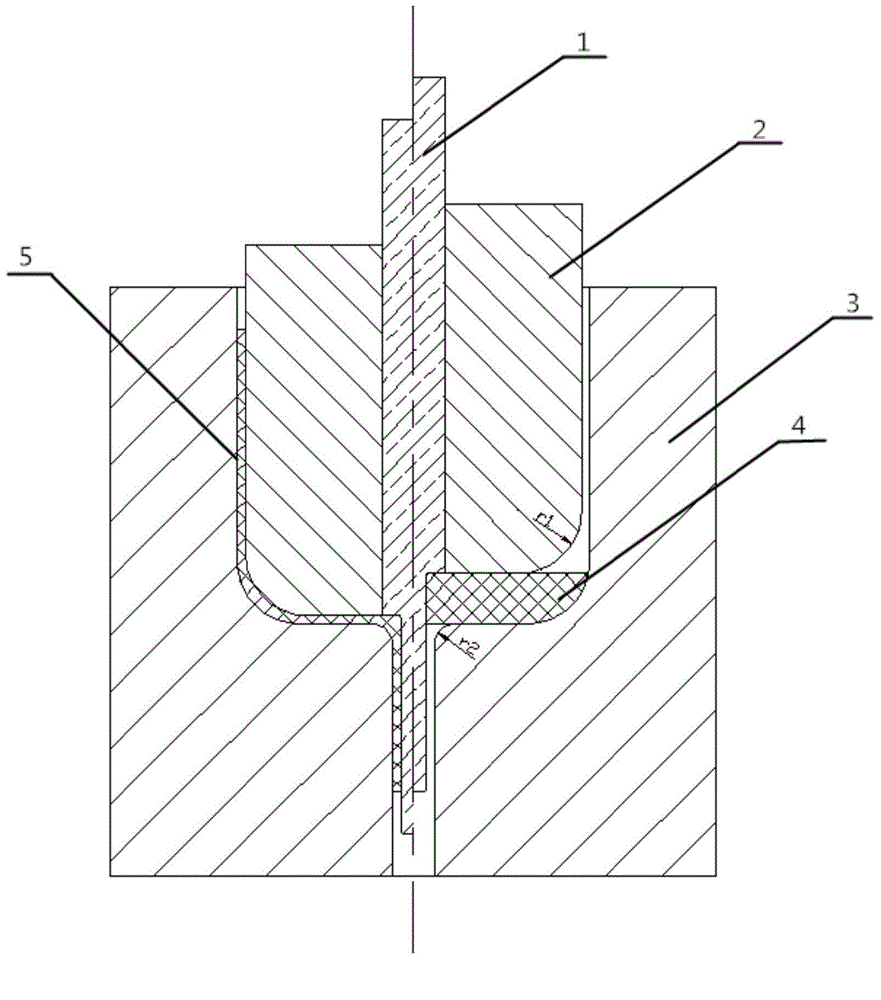

[0033] 3. Forward and reverse compound extrusion, at room temperature, using a punch with a mandrel and a cup-shaped die for extrusion, the downward speed of the punch during extrusion is 10mm / s; during the extrusion process, a part of the billet is directed downward Extrude to form the lower end stem of the cup-shaped vessel, and another part of the blank is extruded upward and reversely to form the upper cup of ...

Embodiment 2

[0041] Such as figure 1 As shown, this embodiment includes the following steps:

[0042] 1. Billet making, the pure platinum billet with hollow structure is obtained through casting process, and then annealed.

[0043] 2. The surface is copper-plated, and a layer of 20μm copper coating is plated on the surface of the hollow blank by electroplating. The specific electroplating process parameters are: main salt concentration 60g / L, current density 20A / dm 2 , the temperature of the electroplating solution is 50°C, and the electroplating time is 40min.

[0044] 3. Forward and reverse compound extrusion, at room temperature, using a punch with a mandrel and a cup-shaped die for extrusion, the downward speed of the punch during extrusion is 20mm / s; during the extrusion process, a part of the billet is directed downward Extrude to form the lower stem of the cup-shaped vessel, and another part of the blank is extruded upwards and reversely to form the upper cup of the cup-shaped ves...

Embodiment 3

[0050] Such as figure 1 As shown, this embodiment includes the following steps:

[0051] 1. Billet making, using recycled cup-shaped vessels as raw materials, obtaining pure platinum blanks with hollow structures through casting processes, and annealing them.

[0052]2. The surface is copper-plated, and a layer of 12 μm copper coating is plated on the surface of the hollow blank by electroplating. The specific electroplating process parameters are: main salt concentration 60g / L, current density 20A / dm 2 , the temperature of the electroplating solution is 40°C, and the electroplating time is 25min.

[0053] 3. Forward and reverse compound extrusion, at room temperature, using a punch with a mandrel and a cup-shaped die for extrusion, the downward speed of the punch during extrusion is 15mm / s; during the extrusion process, a part of the billet is directed downward Extrude to form the lower end stem of the cup-shaped vessel, and another part of the blank is extruded upwards and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com