Spray nozzle

A water mist sprinkler and sprinkler body technology, which is applied in fire rescue and other directions, can solve the problems of mandrel, spring, nozzle hole of sprinkler body being easily blocked by insects, sandstorm, electric leakage, etc., and achieve the effect of improving resistance to water ingress and impurity clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

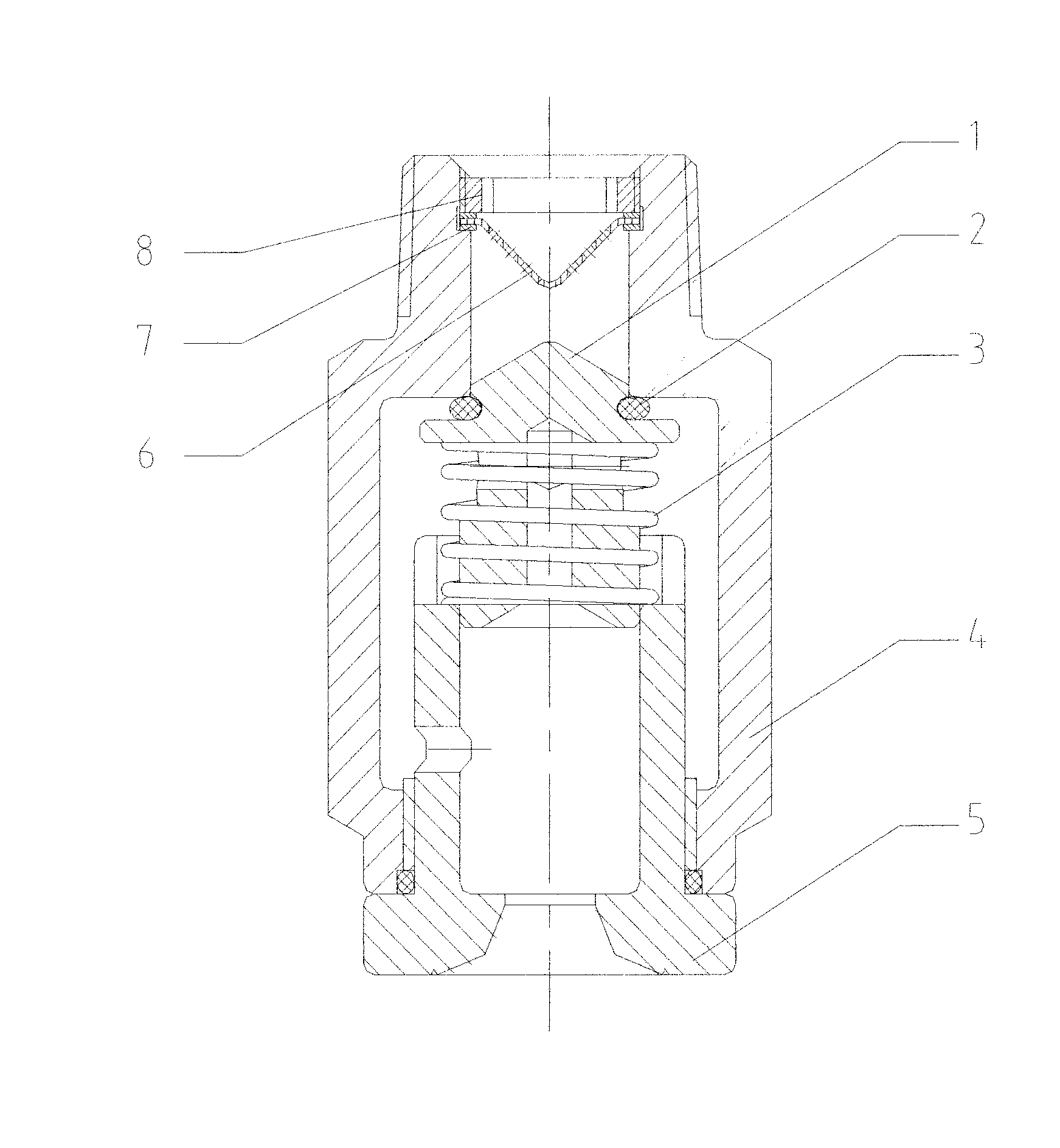

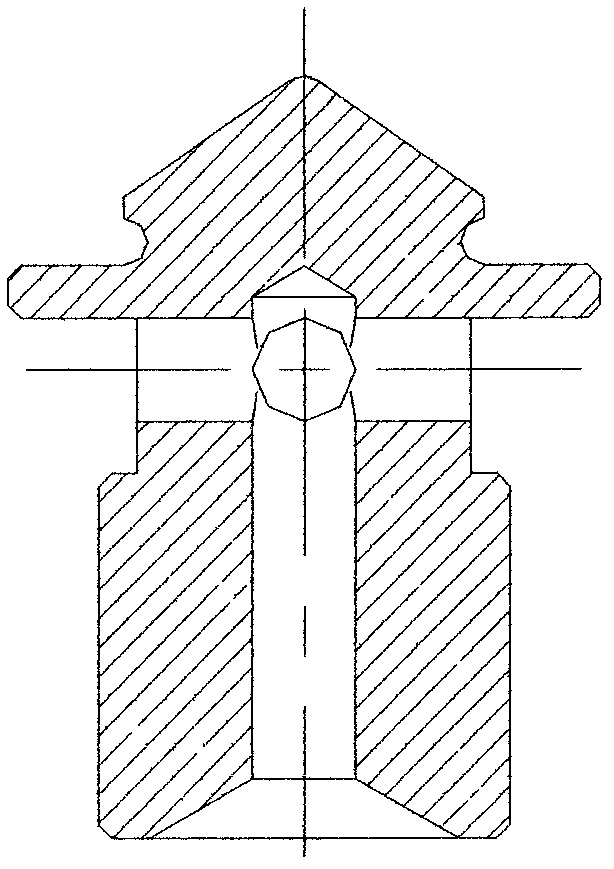

[0021] The water mist nozzle consists of a nozzle body (4), a nozzle (5), a mandrel (1), a spring (3), an O-ring (2), a cone filter (6), a copper gasket (7), a lock Tightly buckle (8) to form. Both sides of the cone-shaped filter are lined with copper gaskets, which are installed at the inlet of the water inlet channel of the nozzle body and fastened by a locking buckle; the O-shaped sealing ring is set in the sealing groove of the mandrel; the mandrel is pushed by the spring to move to the water inlet, Make the O-ring contact with the top surface of the abdominal cavity of the nozzle body to keep the sealing state. The mandrel sleeve is fitted with a spring in the nozzle inlet hole. Normally, under the thrust of the spring, the mandrel contacts the O-shaped sealing ring with the top surface of the abdominal cavity of the nozzle body, so that the water mist nozzle is kept in a closed and sealed state. At the beginning of spraying, because the water pressure of the pipe netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com