Blast furnace molten hot slag recycling technology adopting hot molten salt method

A technology of melting heat and hot molten salt, applied in recycling technology, process efficiency improvement, ammonium sulfate and other directions, can solve the problems of solid waste accumulation, a large amount of solid acid-base waste residue, high product cost and uneconomical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

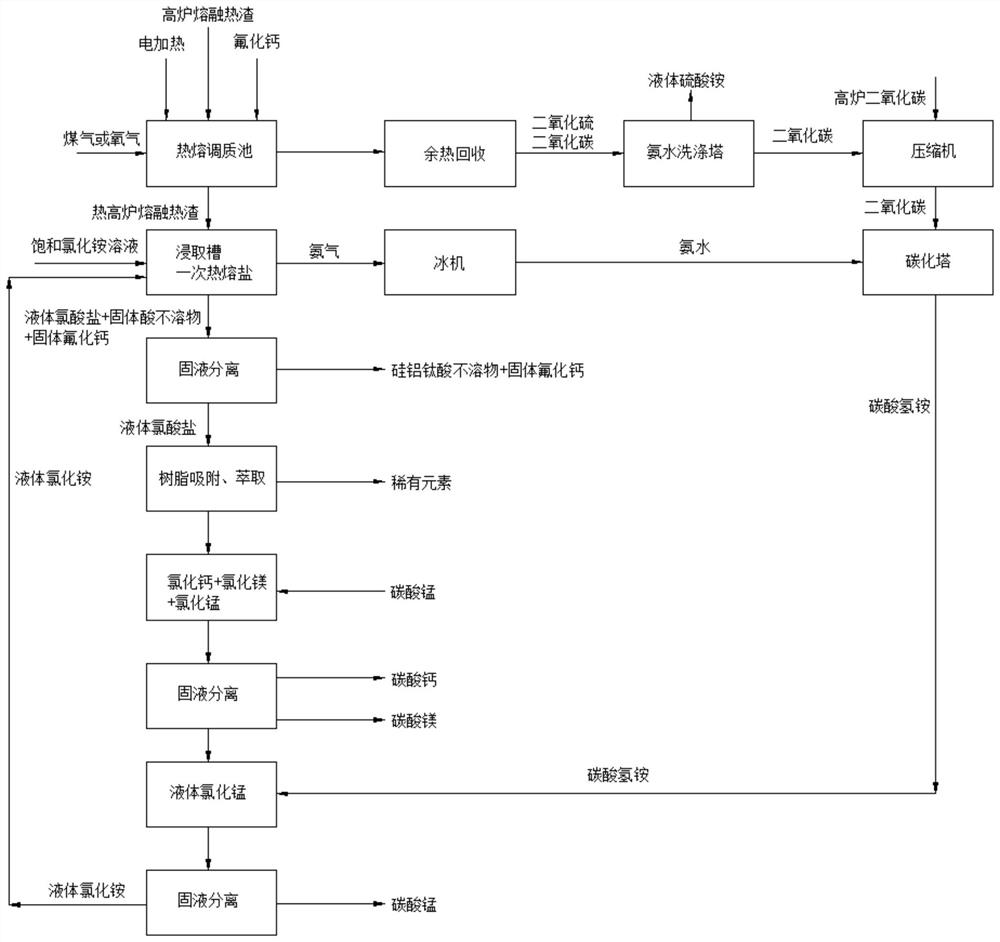

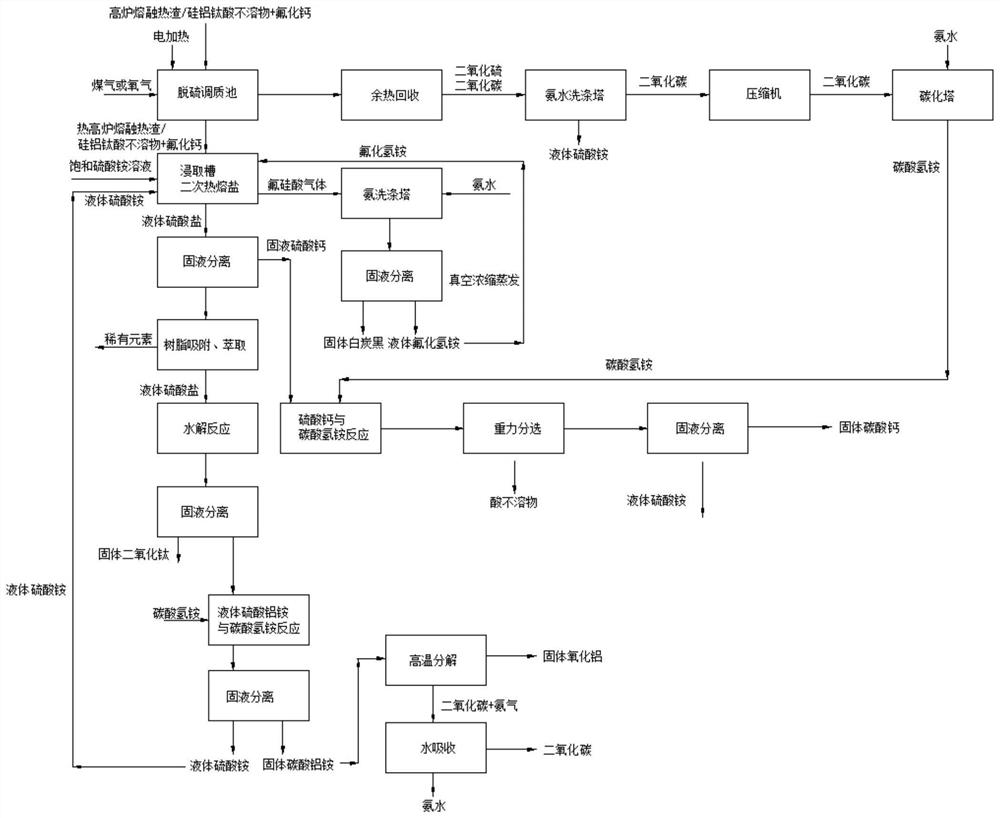

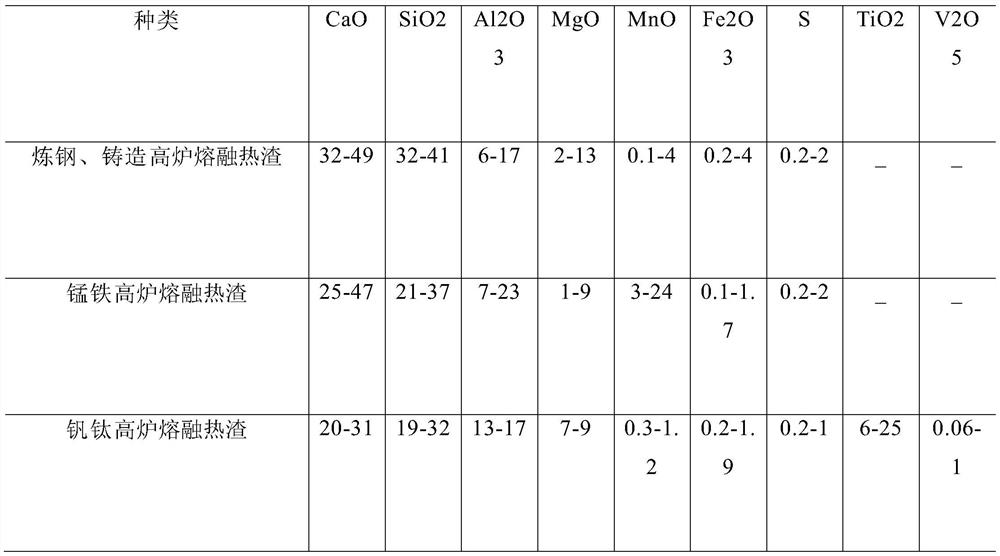

[0069] Such as figure 1 and 2 As shown, the present invention provides a kind of blast furnace molten hot slag hot molten salt method recycling process, comprises ammonium chloride process and / or ammonium sulfate process, and ammonium chloride process comprises the following steps:

[0070] S11: Blast furnace molten hot slag is desulfurized (1400-1600°C) at the same time as iron is recovered by high temperature pyrolysis in the hot molten slag quenching and tempering pool under the condition of oxygen or gas, and the hot molten slag is adjusted by electric heating. The mass pool is heated to maintain the appropriate temperature of the blast furnace molten hot slag. At high temperature, the activity of the oxide is high, and the reaction with the subsequent ammonium chloride is more thorough; new blast furnace molten hot slag, carbon dioxide and sulfur dioxide are generated, and after waste heat recovery , the sulfur dioxide is washed by the ammonia washing tower to generate l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com