A kind of method for removing organic impurities in 2-ethylanthraquinone production waste sulfuric acid water

A technology of organic impurities and ethyl anthraquinone, applied in the direction of magnesium sulfate, chemical instruments and methods, water pollutants, etc., can solve the problems of incomplete precipitation, high steam consumption, easy damage, etc., and achieve the goal of improving quality and saving steam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

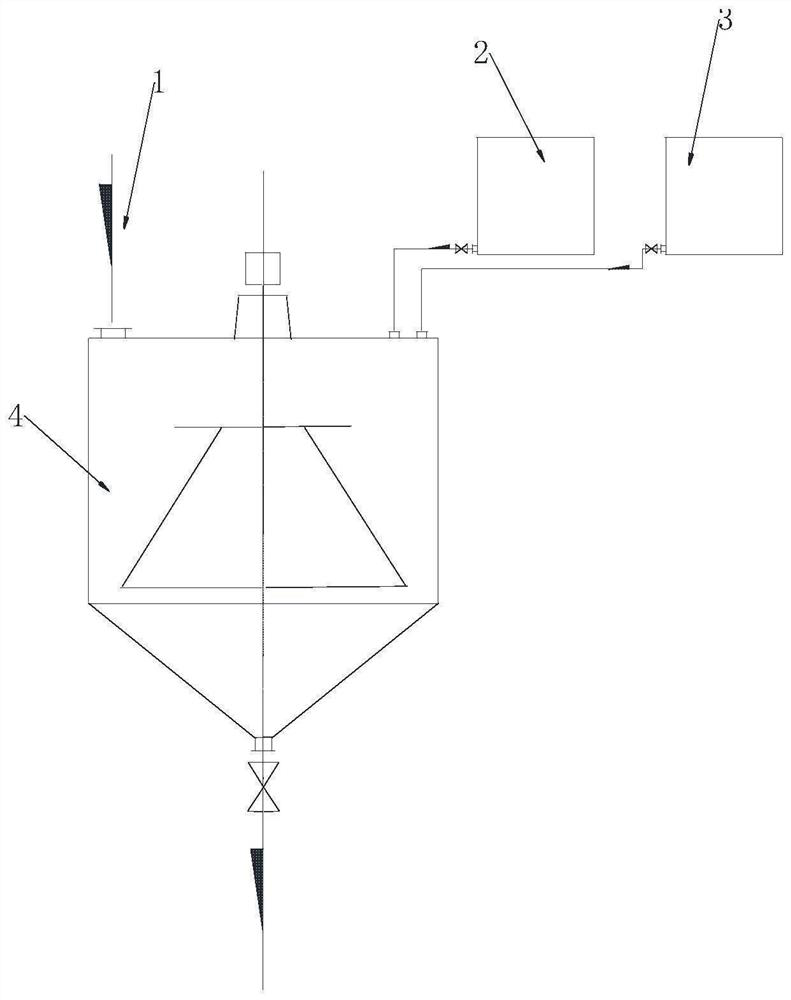

Image

Examples

Embodiment 1

[0044] S1: All the waste acid water produced by the production of 2-ethylanthraquinone is filtered by a plate and frame filter press, filtration temperature: normal temperature; filtration pressure ≤ 10Kg / ㎝ 2 After filtering the solid particles in the waste acid water, it is sent to the waste sulfuric acid water pretreatment storage tank for use. The solid particulate organic waste filtered out is packed in bags and treated as hazardous waste.

[0045] S2: Extract 49m from the mother liquor pool to be purified 3 Magnesium sulfate mother liquor is placed in the reactor, the reactor is opened and stirred, controlled at 24 rev / min, and then 5.6 tons of magnesium oxide powder (content 90%) is added. The acid addition valve is opened and the waste acid water after the S1 step filtration is sent to the reactor Carry out the neutralization reaction, add acid first and then decrease, measure the pH value with B-wide range test paper, until the pH value of the reaction solution is 6.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com