Assembly type movable floor device with variable axial distance for automobile vibration test

A technology of vibration test and vibration device, which is applied in vibration test, measuring device, vehicle test, etc. It can solve the problem that a large range of wheelbase movement cannot be realized, the wheelbase cannot be completely sealed, and the vibration plate cannot be adjusted steplessly and other issues to achieve the effect of meeting the requirements of vibration testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

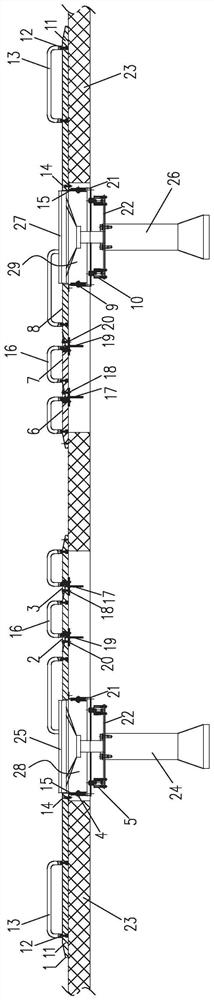

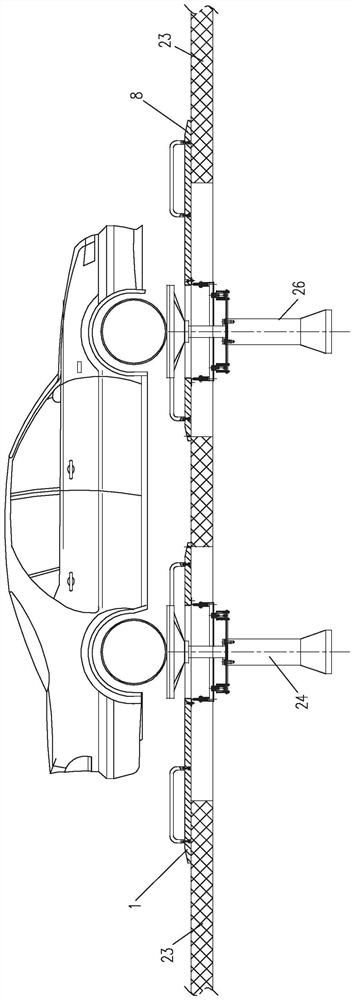

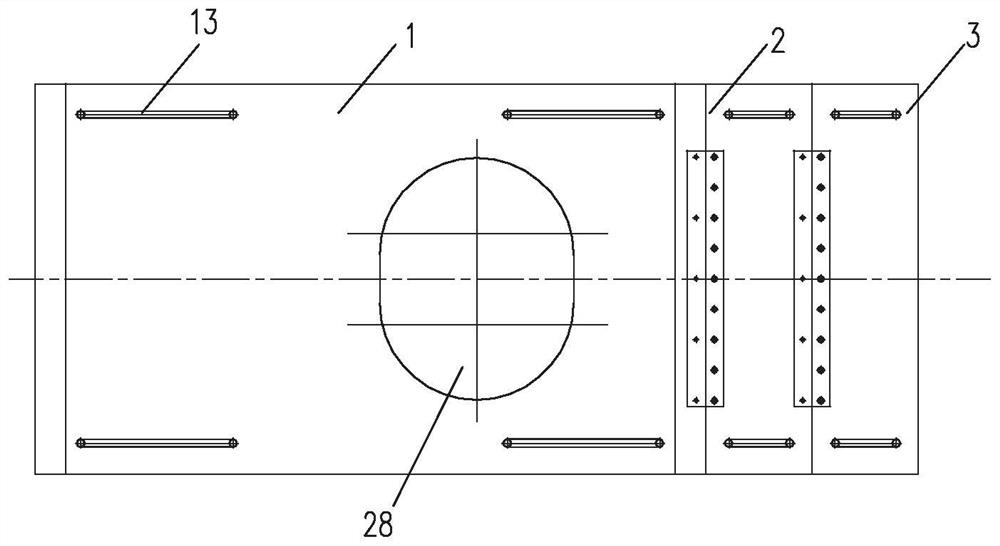

[0026] Such as Figure 1 to Figure 8 The shown assembled mobile floor device with variable axial distance for automobile vibration test includes rear wheel plate assembly and front wheel plate assembly arranged symmetrically front and rear. The rear wheel in this embodiment refers to the left wheel plate assembly shown in the figure. The front wheel is the wheel on the right side shown in the figure, the left side shown in the picture is the rear, the right side shown in the picture is the front, the rear wheel plate assembly and the front wheel plate assembly are mirror images, each Contains one main board and two sub boards.

[0027] Among them, the rear wheel plate assembly includes the rear wheel main seal plate 1, the rear wheel auxiliary seal plate A2, the rear wheel auxiliary seal plate B3, the rear wheel side guide wheel 4 and the rear wheel seal plate support cylinder 5, and the rear wheel seal plate support cylinder 5 There are four, symmetrically installed on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com