Outer box assembling and forming integrated device

A molding device and outer box technology, which is applied in packaging, transportation and packaging, and box production operations, etc., can solve the problems of increased equipment maintenance costs, reduced plant space utilization, and complexity, so as to improve production tempo and reduce equipment maintenance costs , the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

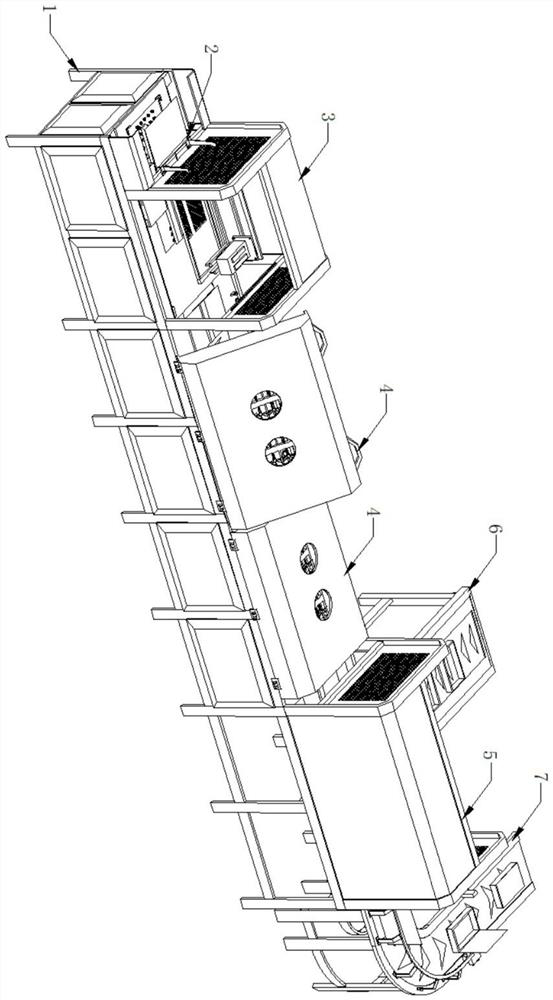

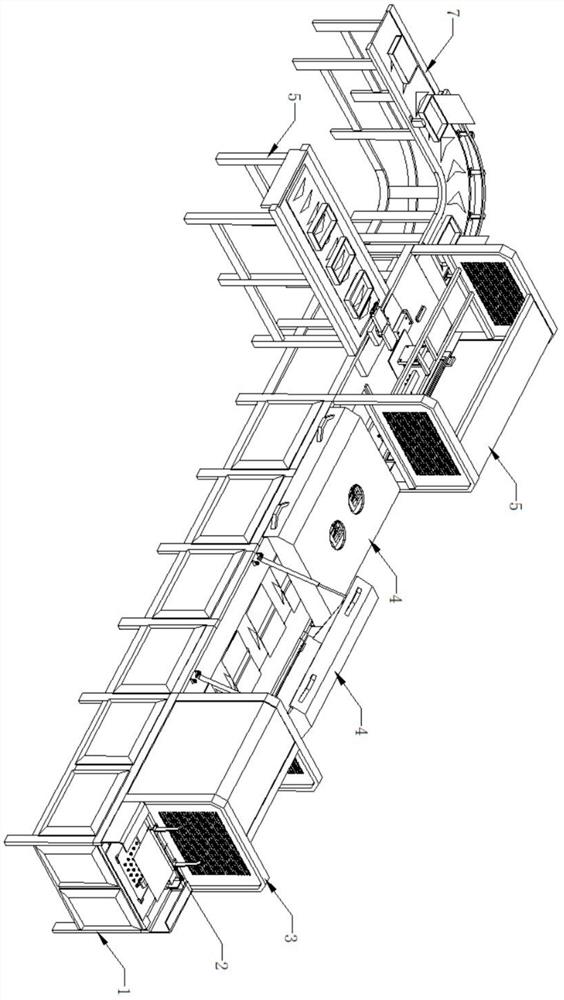

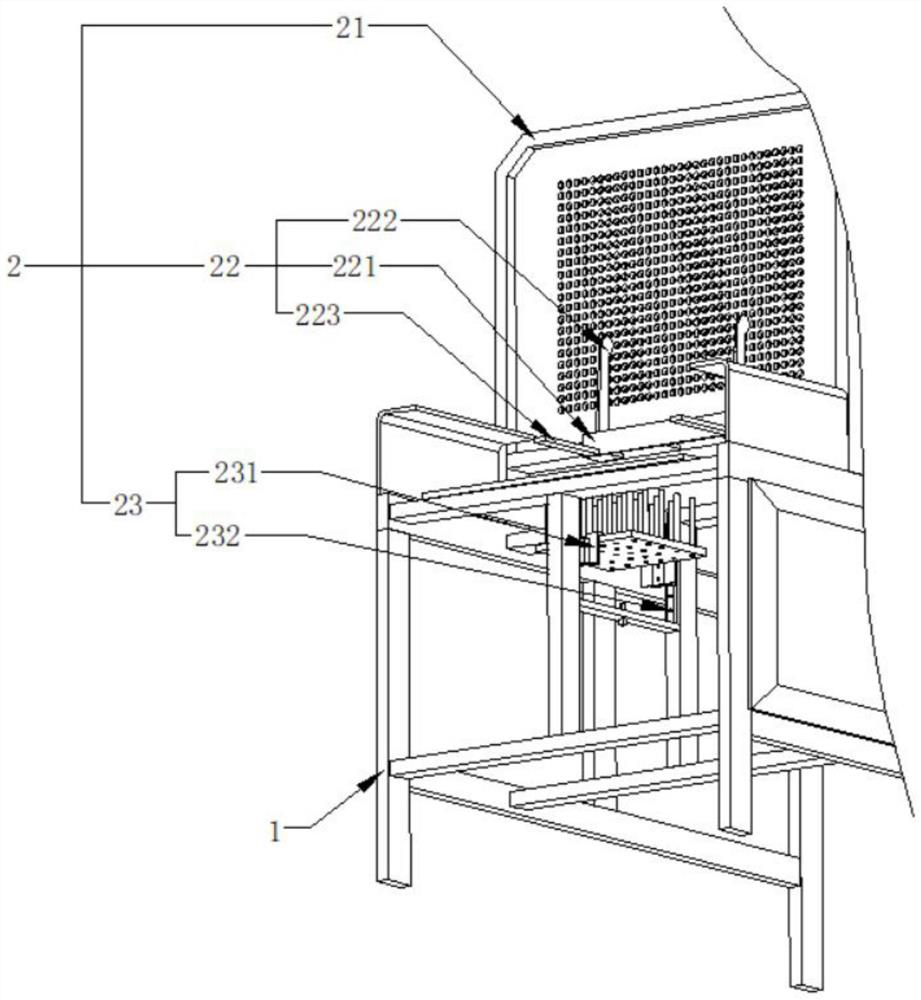

[0025] Such as Figure 1-7 As shown, the present invention provides an integrated device for assembling and forming an outer box, including a bottom bracket device 1, and an outer box feeding device 2 is installed at one end of the bottom bracket device 1, and the outer box feeding device 2 includes a first peripheral frame 21, a second One side of a peripheral frame 21 is equipped with an outer box carrying platform 22, and the bottom inner side of the first peripheral frame 21 is equipped with an outer box picking device 23, and the top surface of the bottom support device 1 is hinged with two drying devices 4 for drying. The device 4 includes a shell stamping part 41. Two handles 42 are symmetrically arranged on one side of the shell stamping part 41. A fixing device 43 is installed inside the shell stamping part 41. A damping rod 44 is movably connected to the inner wall of the shell stamping part 41, and the outer wall of the shell stamping part 41 is An outer box gluing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com