Heat insulation performance testing device and testing method for thermal protection material type selection

A technology of thermal protection materials and testing devices, applied in the direction of material thermal development, etc., can solve the problems of complex testing process, large equipment, unfavorable use, etc., and achieve the effect of low price, simple steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

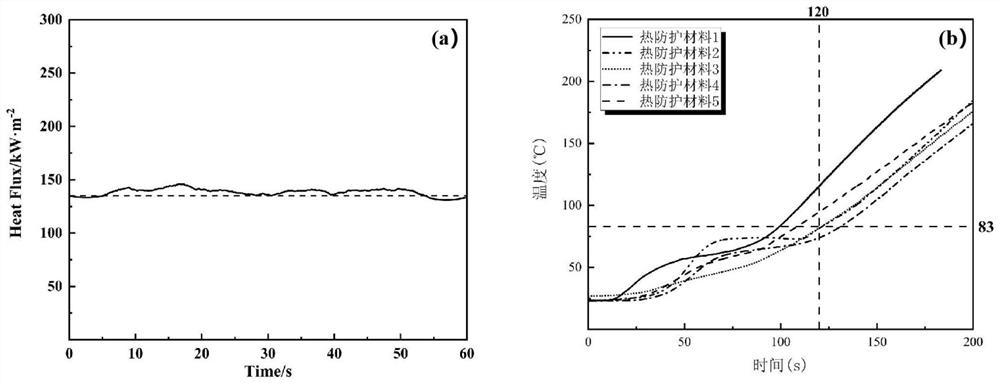

[0041] A thermal protection material is selected by using a thermal insulation performance testing device and a testing method for thermal protection material selection disclosed in the present invention. There are five candidate thermal protection materials, which are named as thermal protection material 1, thermal protection material 2, thermal protection material 3, thermal protection material 4 and thermal protection material 5. The materials are processed into cylindrical samples of Φ30mm×10mm for testing. . The thermal insulation performance of the required thermal protection material is 135kW / m 2 The temperature rise of the backside of the material does not exceed 60℃ when heated for 120s under the same heat flux density.

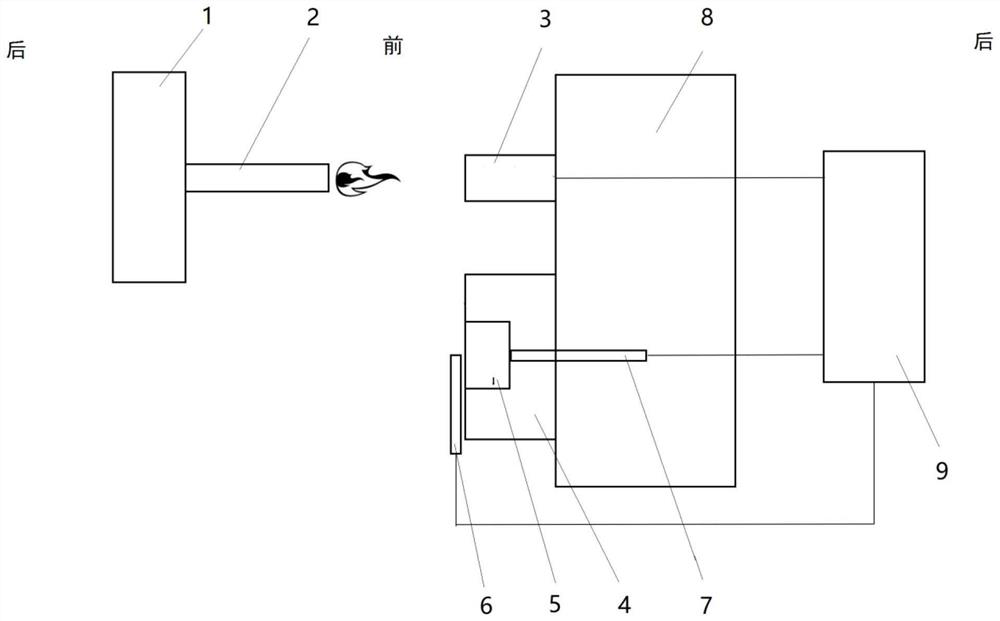

[0042] The thermal insulation performance testing device includes four modules, namely, a thermal insulation module, a heating module, a testing module and a mechanical module. The thermal insulation module is a refractory brick with soft quality a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com