Cooling test assembly unit and aging cooling equipment

A technology for assembling units and cooling components, which is used in measurement devices, electronic circuit testing, and electrical measurement. It can solve problems such as the inability to meet high-power optical chip aging test requirements, avoid deformation, avoid misoperation, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

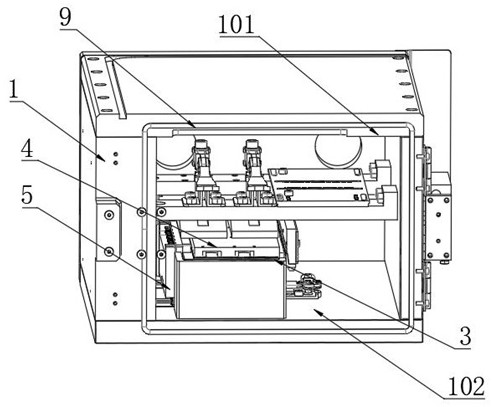

[0066] The embodiment of the present application discloses a cooling test assembly unit, which is used to provide a low-temperature and full-power environment to complete the testing of chips, especially the detection of optical chips, and this application is aimed at testing high-power chips , during the specific test, the chip is welded on the copper substrate, and then the assembled copper substrate is assembled in the unit for testing.

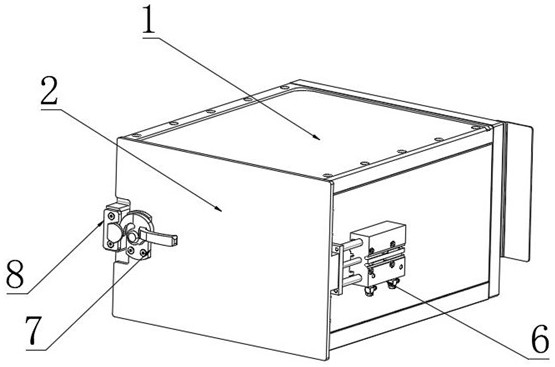

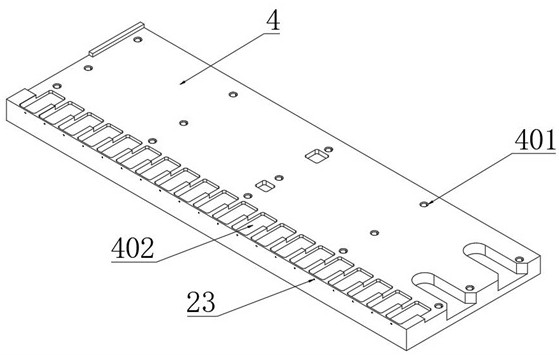

[0067] In one embodiment, as figure 1 , 2 As shown, the structure of the cooling test assembly unit includes:

[0068] Box 1, the box 1 is a sealed cavity 102 with an opening 101 on one side. The box 1 is composed of a plurality of plate-like parts, which can be welded or bolted. It is necessary to ensure that the cavity formed around In order to seal the cavity 102, so that the temperature environment inside the subsequent sealed cavity 102 will not be disturbed by the external environment; in order to further improve the cooling effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com