Mechanical property testing device with improved anti-interference performance

A technology for mechanical properties and testing devices, applied in measurement devices, strength properties, scientific instruments, etc., can solve the problems of difficult maintenance and replacement, low work efficiency, affecting accuracy, etc., to facilitate disassembly and replacement, improve work efficiency, reduce The effect of lateral friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

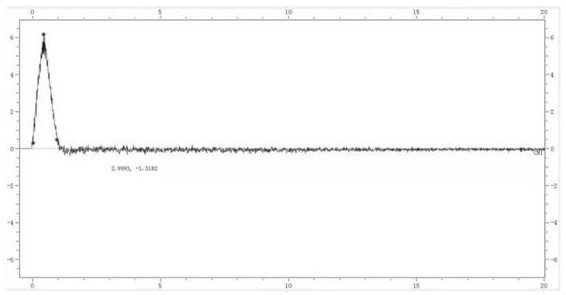

[0032] like figure 2 As shown, a mechanical characteristic testing device with improved anti-interference performance includes a falling ball 1 and a bracket 2 and an acceleration sensor 3 installed on the front of the falling ball 1, and the acceleration sensor 3 is installed on the midpoint of the front of the falling ball 1, and the falling ball 1. A mica sheet 4 is provided at the connection with the acceleration sensor 3. The support 2 includes a first connecting piece 5 and a second connecting piece 6. The distance from the acceleration sensor 3 to the first connector 5 and the second connector 6 is L, the distance from the acceleration sensor 3 to the edge of the falling ball 1 is R, and L is greater than or equal to When L is greater than or equal to , the interference to the waveform can be avoided, the upper ends of the first connector 5 and the second connector 6 are overlapped with a third connector 7, and a handle 8 is connected to the third connector 7, which...

Embodiment 2

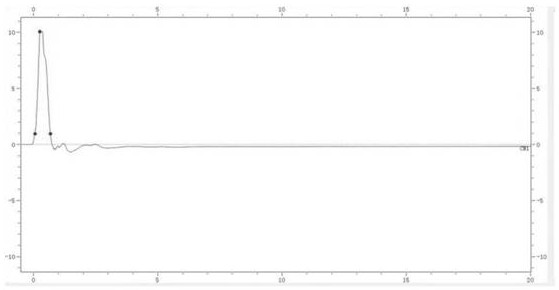

[0034] like image 3 As shown, the overall structure is the same as that of Embodiment 1, and the installation of the acceleration sensor 3 on the front of the falling ball 1 has been further improved, specifically as follows: the front of the falling ball 1 is a plane 9, and an internal thread hole is provided on the front of the falling ball 1 10. The bottom surface of the acceleration sensor 3 is provided with a threaded rod 11, the mica sheet 4 is located on the front of the falling ball 1, the threaded rod 11 is inserted into the internally threaded hole 10 through the mica sheet 4, and the acceleration sensor 3 passes through the screw thread at the bottom The rod 11 is fixed in the internal threaded hole 10 to reduce lateral displacement, so as to reduce signal interference caused by friction.

Embodiment 3

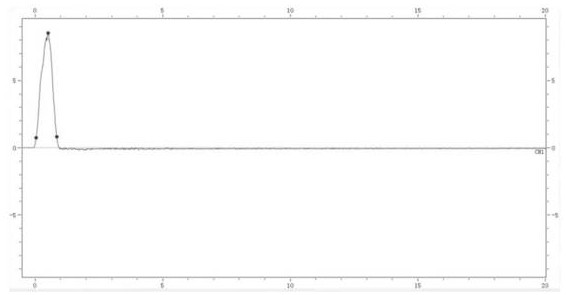

[0036] like Figure 4 As shown, the overall structure is the same as that of Embodiment 1, and the installation of the acceleration sensor 3 on the front of the falling ball 1 has been further improved, specifically as follows: the front of the falling ball 1 is a plane 9, and a platform groove 12 is set on the front of the falling ball 1 , the bottom surface of the acceleration sensor 3 is provided with a threaded rod 11, the bottom surface of the platform groove 12 has an internal threaded hole 10, the mica sheet 4 is embedded in the platform groove 12, and the threaded rod 11 passes through the mica sheet 4 is inserted into the internal threaded hole 10, and the platform groove 12 is used to fix and embed the mica sheet 4 to reduce the lateral displacement of the mica sheet 4, so as to reduce signal interference caused by friction.

[0037]The falling balls 1 of Examples 1-3 are all hemispheres, the plane section of the hemisphere is the front, the apex of the hemisphere co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com