Assembling method for aligning and positioning through self-weight sinking in motor stator hot jacket process

A shrink-fit process and motor stator technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as rotor sweeping and stator mounting deviation, so as to avoid stator mounting deviation and ensure product quality , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

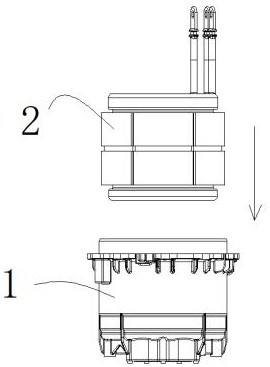

[0022] Such as figure 1 , 2 As shown, the motor includes a cylindrical rotor (not shown in the figure), a stator 2 and a motor housing 1 . The stator 2 has a cylindrical cavity, the stator 2 is press-fitted in the motor housing 1 , and the rotor is installed in the cylindrical cavity of the stator 2 .

[0023] The shrink-fit process of the stator 2 described in this application is to install the stator 2 into the housing 1 at high temperature. Due to the unavoidable deviation of the installation angle and the deviation of the direction of external pressure in the traditional press-fit method, it is difficult to guarantee the completion. The axis line of the press-fitted stator 2 coincides with the axis line of the housing 1, that is, the stator assembly deviation occurs during press-fitting.

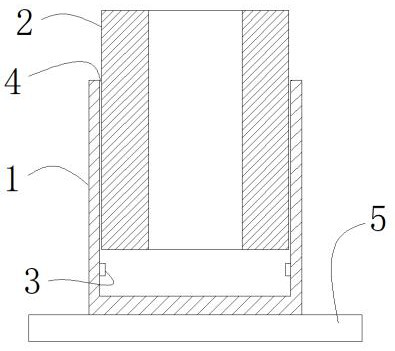

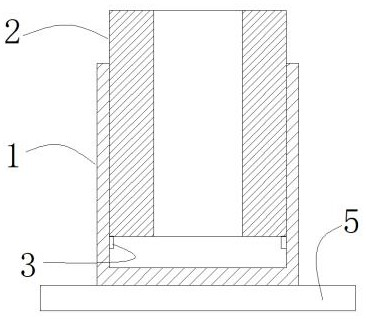

[0024] Such as figure 2 , 3 As shown, an assembly method for aligning and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com