Classification type industrial molten metal separation equipment for metallurgy

An industrial metal and liquid separation technology, applied in separation methods, filtration separation, fixed filter element filters, etc., can solve the problems of high labor intensity, low separation efficiency, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

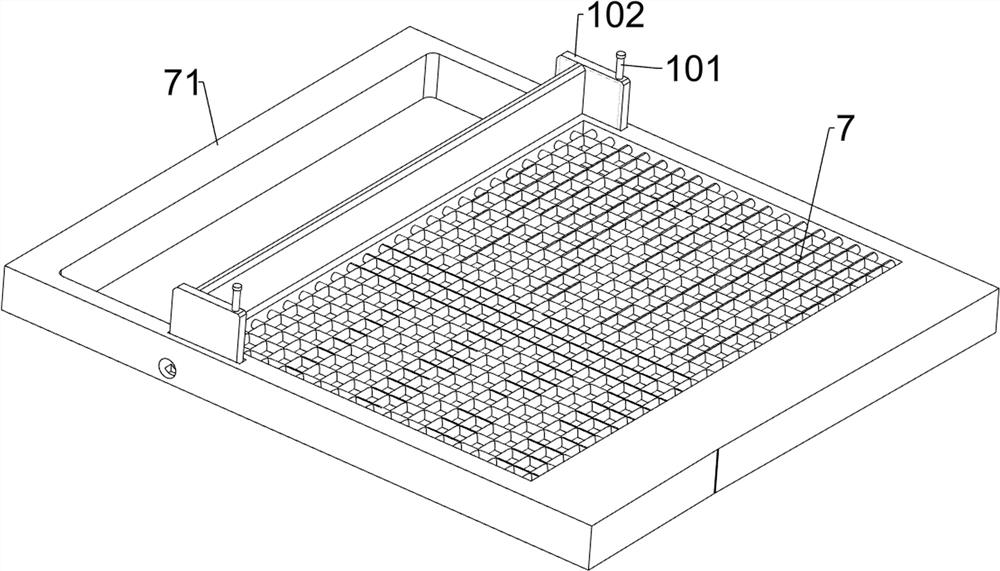

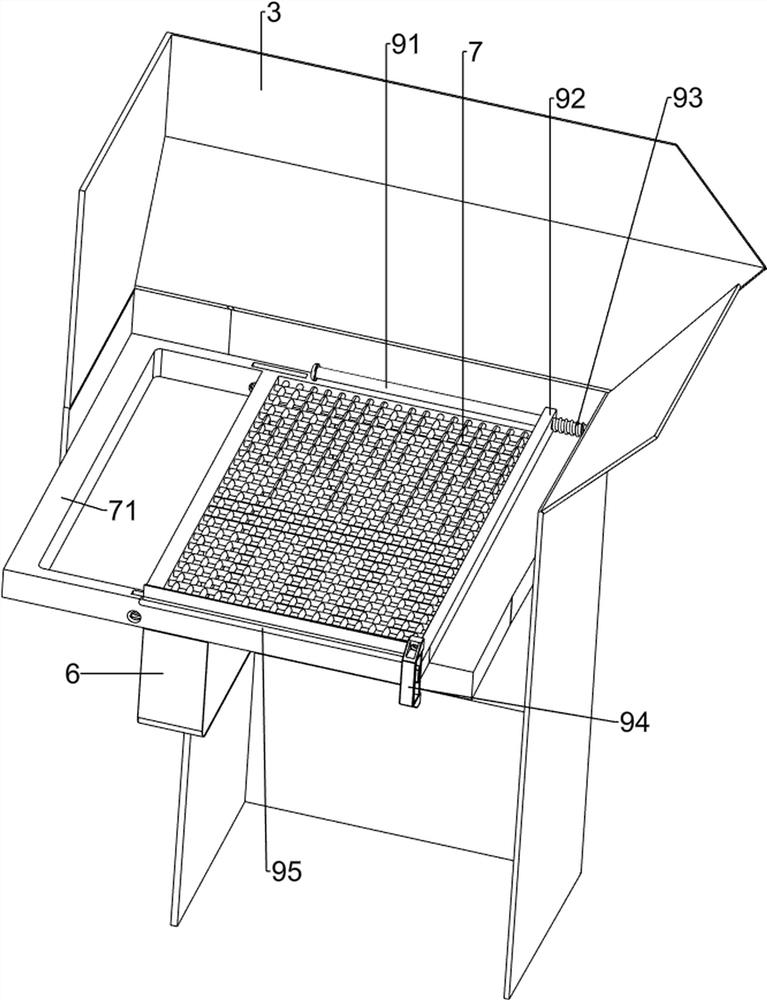

[0070] A classified type metallurgical industrial liquid metal separation equipment, such as Figure 1-7 As shown, it includes a support frame 1, a discharge frame 2, a frame 3, a solid discharge pipe 4, a liquid filling tank 5, a reaction liquid storage tank 6, a first filter screen 7, a second filter screen 8, and a liquid outlet pipeline 61 , a fixed frame 71, a pusher mechanism 9 and an opening and closing mechanism 10, a support frame 1 is arranged symmetrically on both sides of the top of the discharge frame 2, and a frame 3 is arranged on the top of the discharge frame 2, and the left side of the top of the frame 3 is connected to the discharge frame. A solid discharge pipe 4 is connected between the left side of the top of the material rack 2, a liquid filling tank 5 is provided on the upper part of the inner wall of the frame 3, a reaction liquid storage tank 6 is provided on the left side of the upper part of the inner wall of the frame 3, and a reaction liquid storag...

Embodiment 2

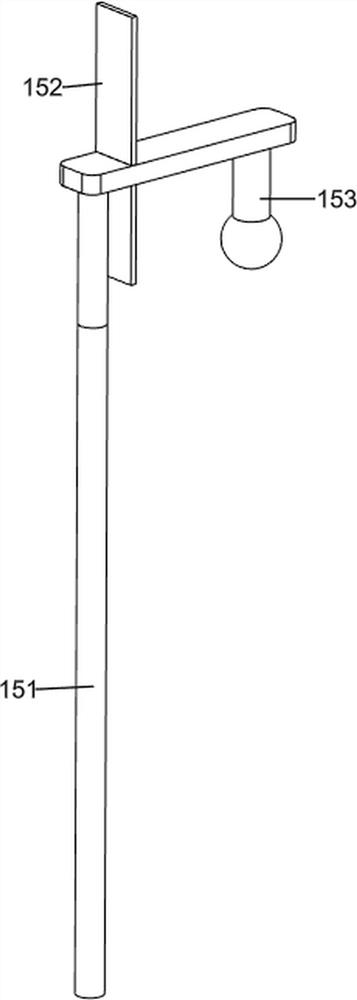

[0077] On the basis of Example 1, such as Figure 8-16 Shown, also comprise turning mechanism 11, turning mechanism 11 comprises arc block 111, closing frame 112, the 3rd spring 113 and projection 114, and fixed frame 71 bottom left side rotation type is provided with closing frame 112, and closing frame 112 front An arc block 111 is provided at the top, the closing frame 112 is rotatably connected with the fixed frame 71, the closing frame 112 is rotatably connected with the frame 3, the closing frame 112 is wound with a third spring 113, and the third spring 113 is connected between the closing frame 112 and the frame 3, the front and rear sides of the arc block 111 are provided with projections 114, the projections 114 on the same side cooperate with the door stop frame 102 on the same side, and the long rod 95 cooperates with the arc block 111.

[0078] The long rod 95 moves to the left to drive the arc block 111 to rotate, thereby driving the protrusion 114 and the closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com