ECP construction method and installation device

An installation device and installation assistance technology, applied in the direction of metal processing, etc., can solve the problems of not being able to adapt to deformation cracks, falling off and falling high-altitude parabolic objects, etc., and achieve the effects of improving efficiency, facilitating installation and removal, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

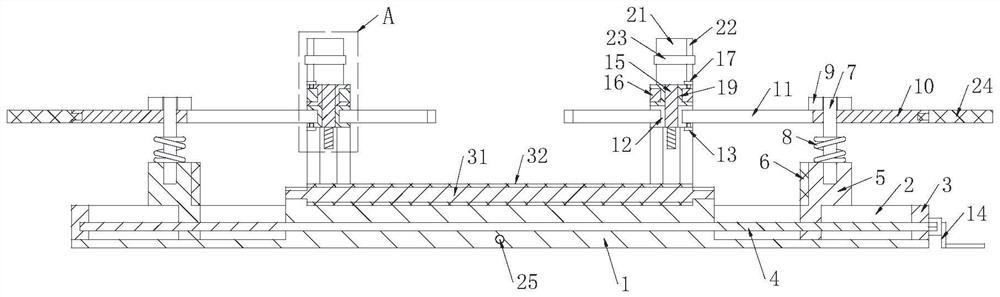

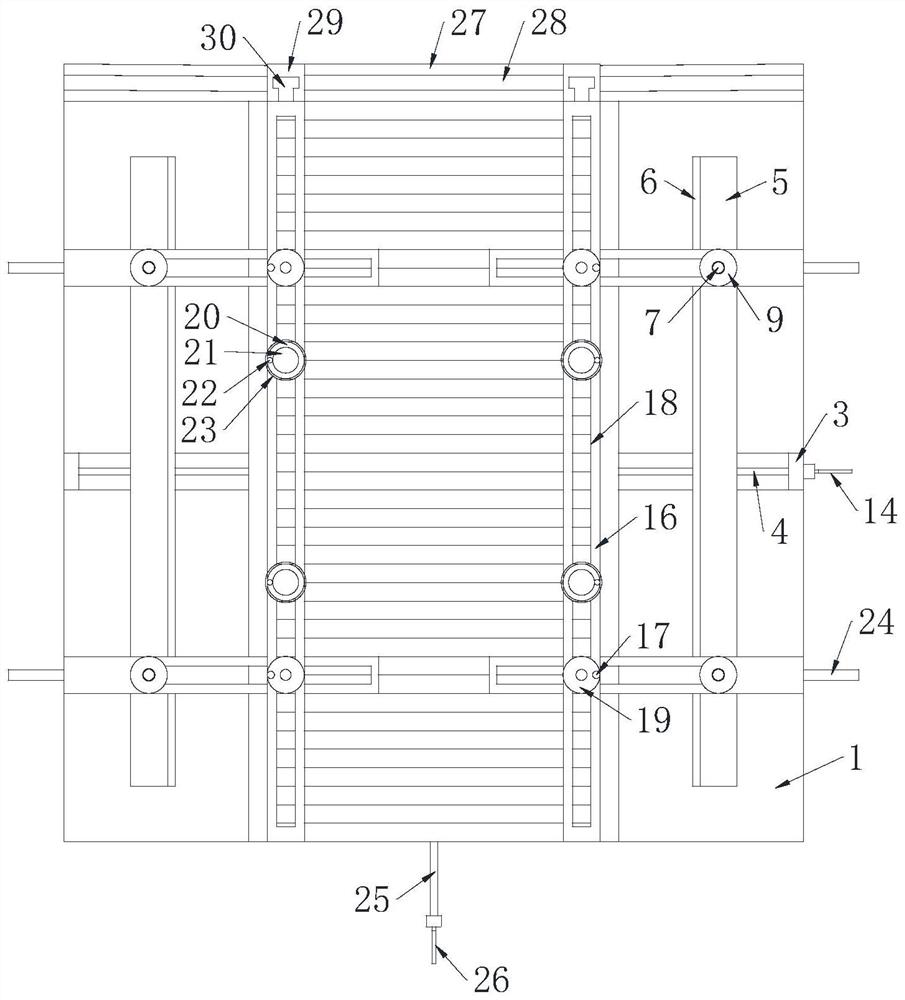

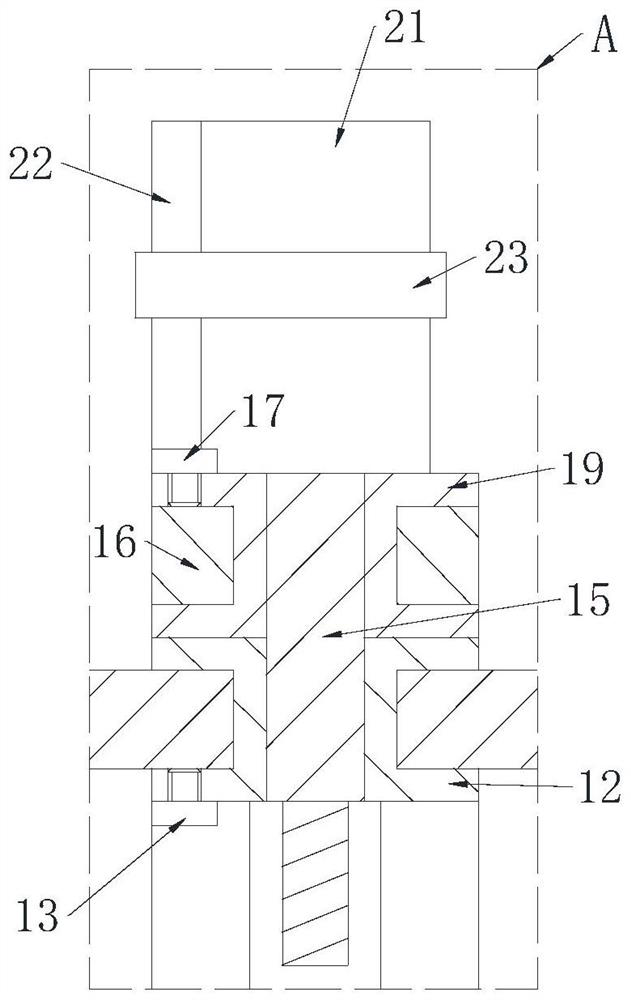

[0035] see Figure 1-4As shown, an ECP construction installation device includes a drilling bottom plate 1, a second threaded shaft 25, a second handle 26 and an installation auxiliary unit; the hole on the drilling bottom plate 1 is threadedly inserted with the second threaded shaft 25; One end of the second threaded shaft 25 is sleeved with a second handle 26; the other end of the second threaded shaft 25 is rotatably sleeved with a synchronous plate 27; the synchronous plate 27 is provided with a synchronous slot 28; the synchronous There is a second slider 29 symmetrically fastened and slidably connected in the groove 28; a third slider 30 is connected to the second slider 29 by slotting and sliding; the third slider 30 is vertically fixed with a vertical Plate 16; the vertical plate 16 is provided with a vertical groove 18; a plurality of third sliding sleeves 20 are fastened and slidably connected in the vertical groove 18; a fixed shaft is fixedly connected to the third...

Embodiment approach

[0052] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, a plurality of support columns 33 are affixed to the lower surface of the drilling floor 1; during operation, the drilling floor 1 and the ground Keep the distance, so as to facilitate the rotation of the first handle 14 and the second handle 26, and it is more convenient to use the palm to carry, and there are more stressed parts; and it is convenient to fix with the ground through the support column 33, thereby ensuring the cutting device in the installation method It can work stably and normally.

[0053] The working principle is to place the ECP board on the protective sleeve 32 and push it forward so that the ECP board is flush with the synchronization board 27, and the second threaded shaft 25 can be driven to rotate by turning the second handle 26, which can drive the limit Rotate the synchronous plate 27 sleeved on the second threaded shaft 25 to move along the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com