Tunnel segment reduced scale test model with cracks and manufacturing method thereof

A technology for test models and tunnel segments, applied in manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problem of affecting the bearing capacity and durability of segments, affecting the safety and normal use of tunnels, and making full-scale segment models Problems such as high cost, achieve the effect of restoring tensile and compressive properties, ensuring accuracy and rigor, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

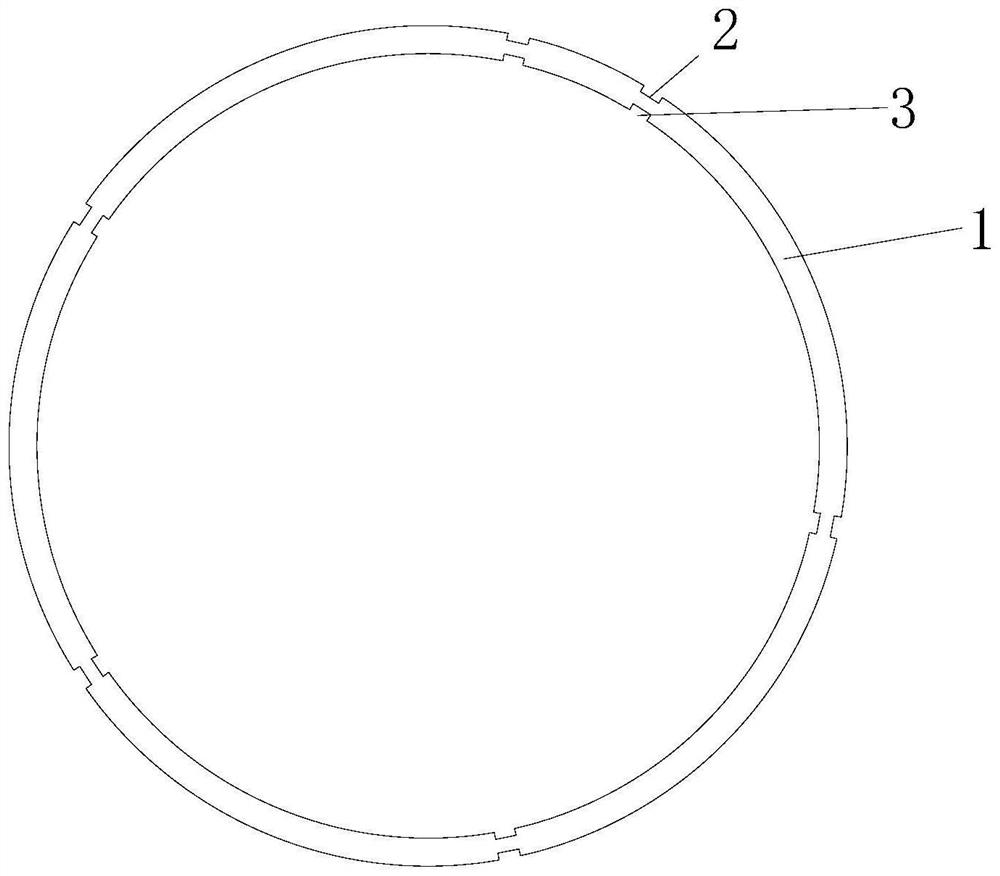

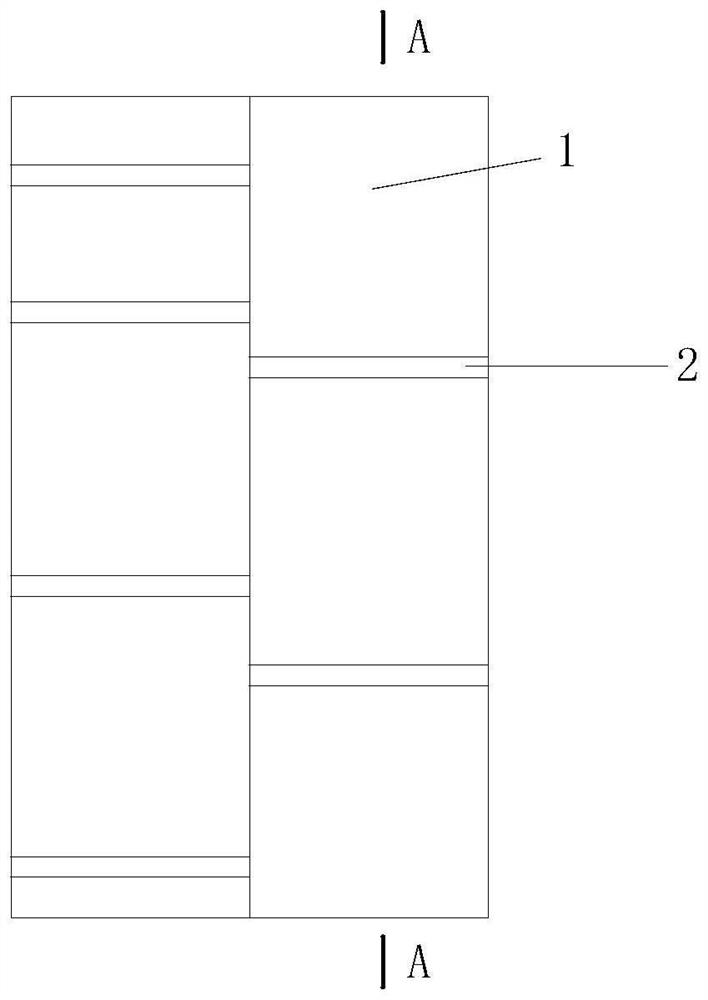

[0050] Such as figure 1 - As shown in 6, in one embodiment, the present invention provides a tunnel segment scale test model with cracks, including: several single segment models and rings for assembling two adjacent single segment models connecting part;

[0051] Wherein, each single segment model includes: pouring formwork, segment main body and reinforcement cage.

[0052] The segment main body is arranged in the internal void of the pouring formwork, and the steel reinforcement cage is arranged in the internal void of the pouring formwork and wrapped by the segment main body.

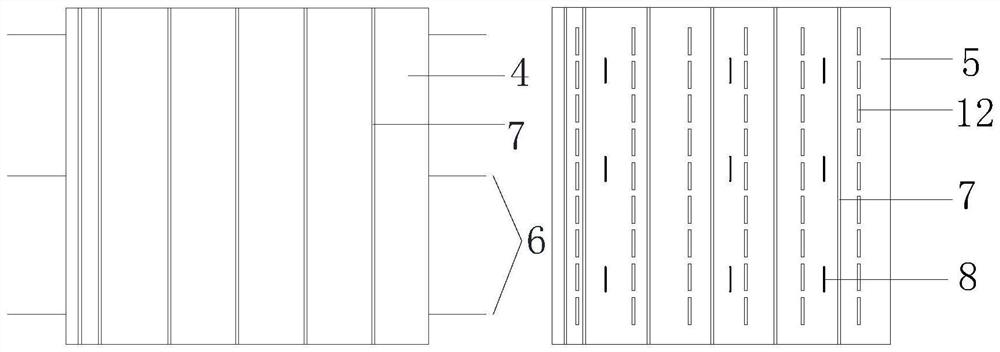

[0053] Such as image 3 As shown, in one embodiment, the pouring formwork includes: an inner formwork 5 , an outer formwork 4 , a fixing ring 6 , a silicone strip 7 and a steel sheet 8 .

[0054] The outer template 4 and the inner template 5 are stacked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com