Brake pad preforming process

A pre-forming, brake pad technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of fragile semi-finished products, difficult to form, etc., and achieve the effect of easy pressing and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

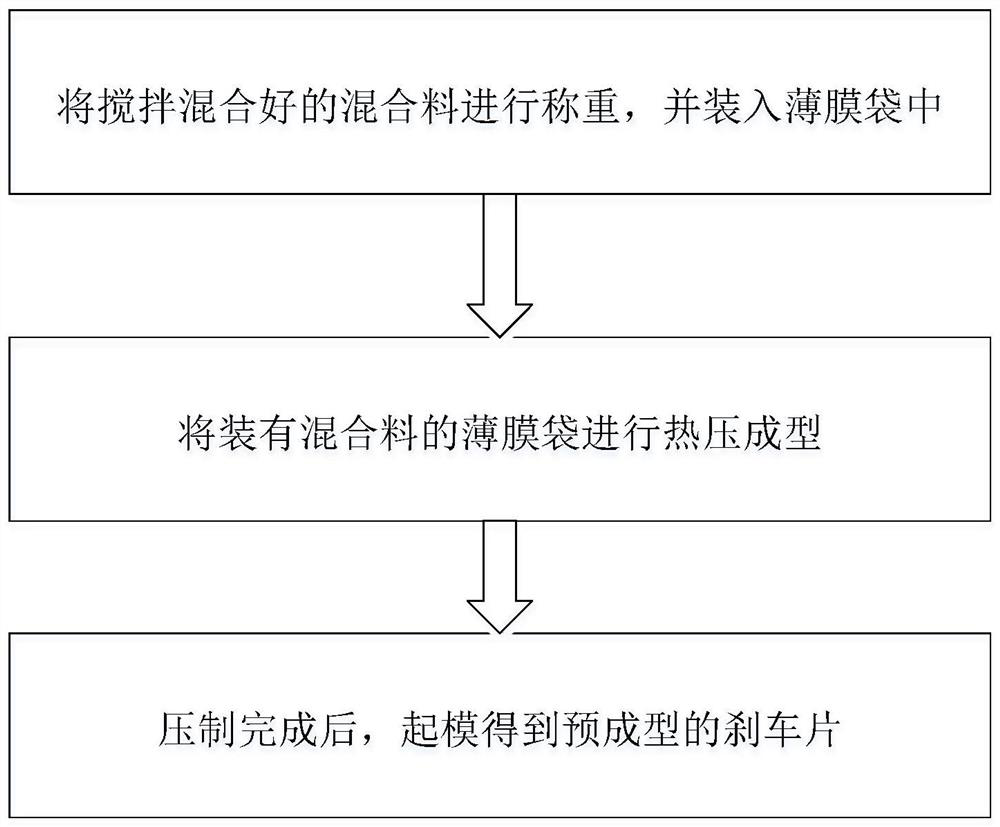

[0016] Such as figure 1 A brake pad preforming process of the present invention is shown, comprising the following steps:

[0017] Step 1. Weigh the mixed material after stirring, and put it into a film bag. The film bag is a polypropylene film bag, and the thickness of the film bag is 3 to 5 wires, so that the film bag Easy to melt and adhere to the surface of preformed brake pads;

[0018] Step 2. Put the film bag containing the mixture into the hydraulic press, press 20mPa, temperature 50 to 70°C, hold the pressure for a set time, and cycle the pressing for a set number of times. The set time is 2 to 4 seconds. The above setting times are 3 times;

[0019] Step 3. After the pressing is completed, the mold is ejected to obtain a preformed brake pad.

[0020] The above preformed brake pads are subjected to curing heat treatment according to the existing process. During the curing heat treatment, the film bag on the surface of the preformed brake pads can be burned, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com