Cold dismantling repair method for track circuit insulation device

A technology of insulating device and track circuit, which is applied to roads, tracks, laying tracks, etc., can solve the problems of uncontrollable manual grinding quality, low grinding efficiency, long grinding time, etc., to save skylight time, short operation time, and construction work simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

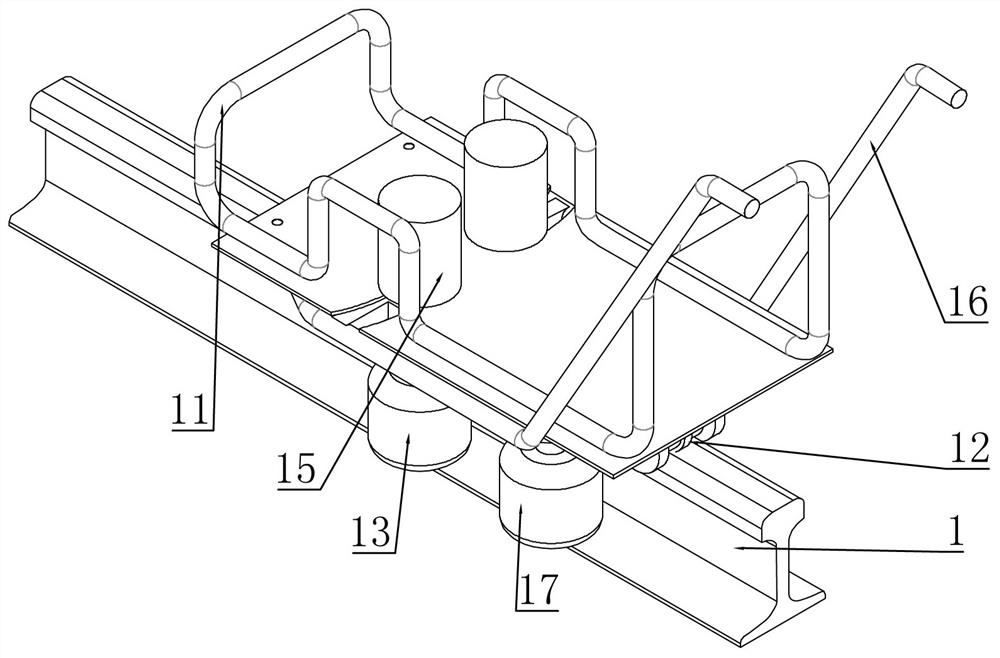

[0030] A cold dismantling and repairing method for a track circuit insulation device, comprising the following steps:

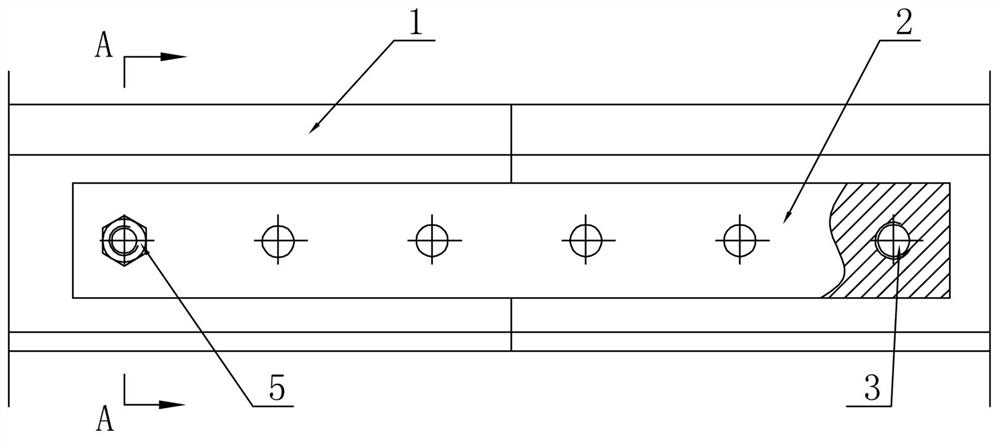

[0031] 1) Before the insulating splint 2 is installed, the connecting hole is processed into the inner thread 3, and it is bonded to the joint of the rail, and the bolt group is used to connect and fasten the connecting hole of the rail;

[0032] 2) When the insulating splint fails and needs to be disassembled, remove all bolt groups, but the insulating splint 2 is still glued to both sides of the rail 1;

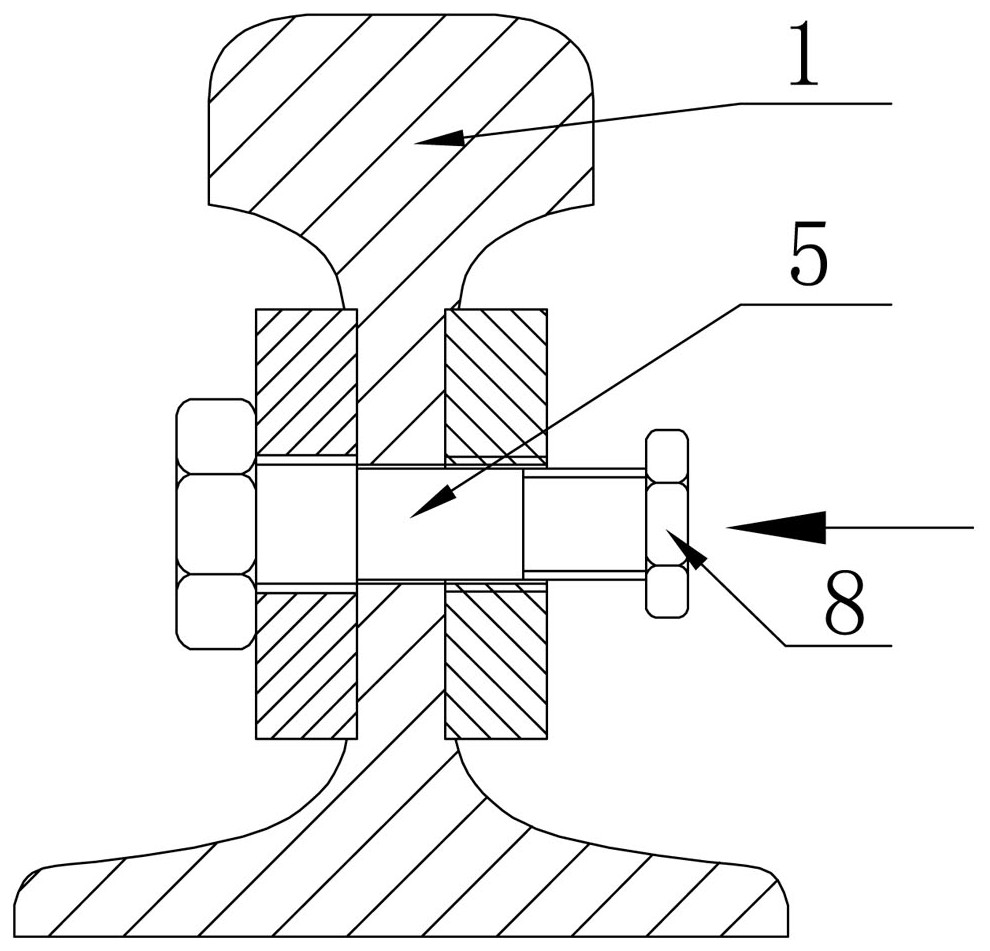

[0033] 3) as figure 1 and figure 2 As shown, one end of the dismantling bolt 5 is threadedly connected with the inner thread 3 of the insulating splint 2 on one side, and the other end extends out of the insulating splint 2 on the other side;

[0034] 4) Hammer the protruding end of the dismantling bolt 5 with a sledgehammer, and the insulating splint 2 threadedly connected with the dismantling bolt 5 is stressed and disengaged from the rail 1 under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com