Gas extraction device for mine drill hole plugging and working method of gas extraction device

A working method and gas technology, used in gas discharge, safety devices, mining equipment, etc., can solve the problems of poor sealing quality, poor grouting, and poor sealing, and achieve good extraction effect, convenient operation, and sealing. tight blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

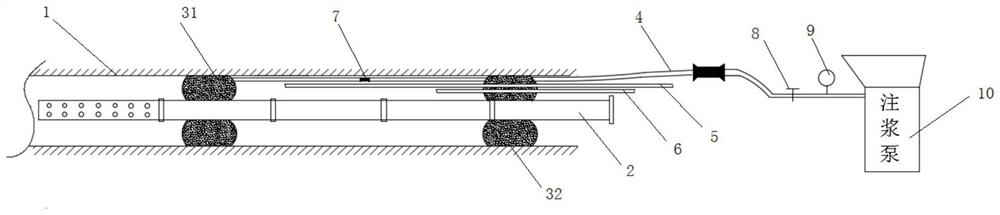

[0020] The invention provides a gas extraction device for mining borehole plugging, such as figure 1 As shown, it includes a sealing pipe 2 for placing in the depth of the borehole 1, and the sealing pipe 2 uses a PVC pipe. The sealing tube 2 is respectively sleeved with a bladder A31 and a bladder B32 at an interval of 10 m. Both the bladder A31 and the bladder B32 are of hollow elastic structure; a grouting tube 10 is also included, which runs through the bladder B32 and extends to the bladder. Inside the bag A31; also includes a deep slurry return pipe 5, one end of which is placed at a distance of 10.5m from the capsule bag A31, and one end is located outside the borehole 1; a shallow slurry return tube 6 is also included, and one end of which is located 20.5m beyond the capsule bag B32 , with one end outside borehole 1. The grouting se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com