Hub bolt hole paint removing device and method thereof

A technology of hub bolts and bolt holes, which is applied in the field of auto parts processing, can solve the problems of lack of protection, waste of labor, environmental pollution, etc., and achieve good results, reduce labor, and reduce useless information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

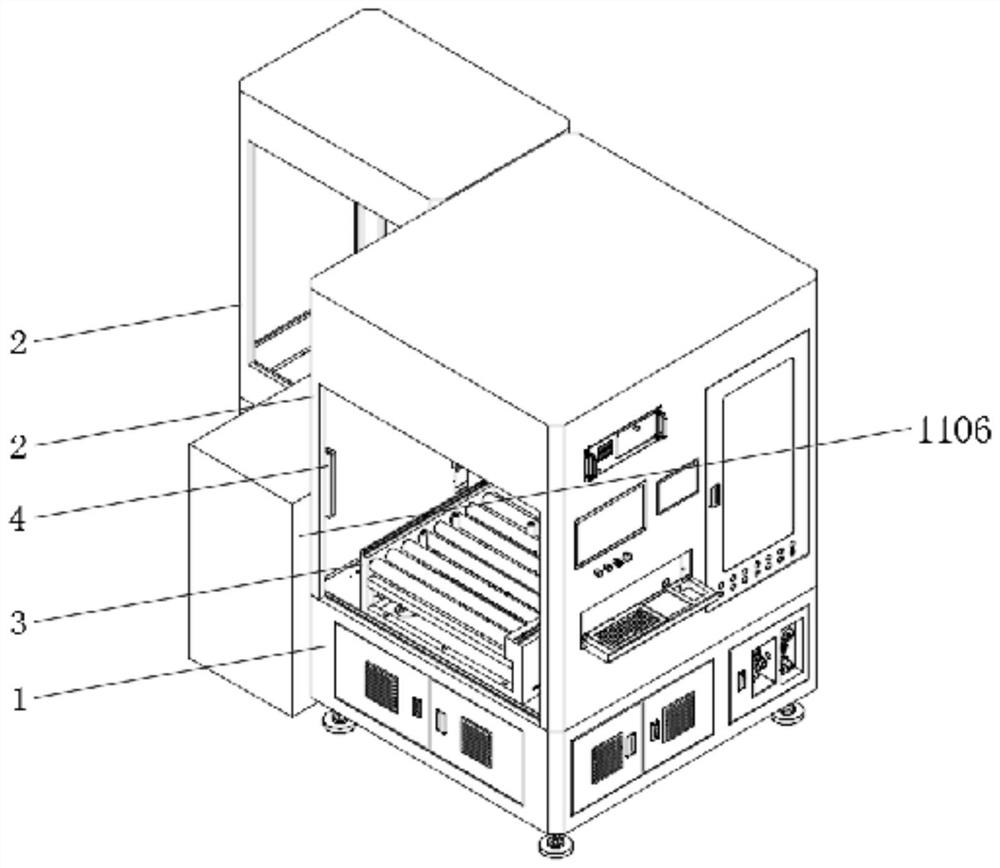

[0035] Example: see figure 1 , the present invention provides a wheel hub bolt hole paint removal device, including a lower frame 1 and a vacuum cleaner 1106, the lower frame 1 is installed with a roller conveying line 3 through bolts for horizontally transporting the wheel hub. The lower frame 1 is also equipped with an upper frame 2 by bolts, which is used to cover and protect the roller conveying line 3 and carry various switches and operation panels. The height measuring grating 4 is installed with bolts on the upper frame 2, and the height measuring grating 4 is provided with two and is respectively located at the left and right ends of the wheel hub feeding on the roller conveying line 3, and is used to detect the dimension height of the wheel hub.

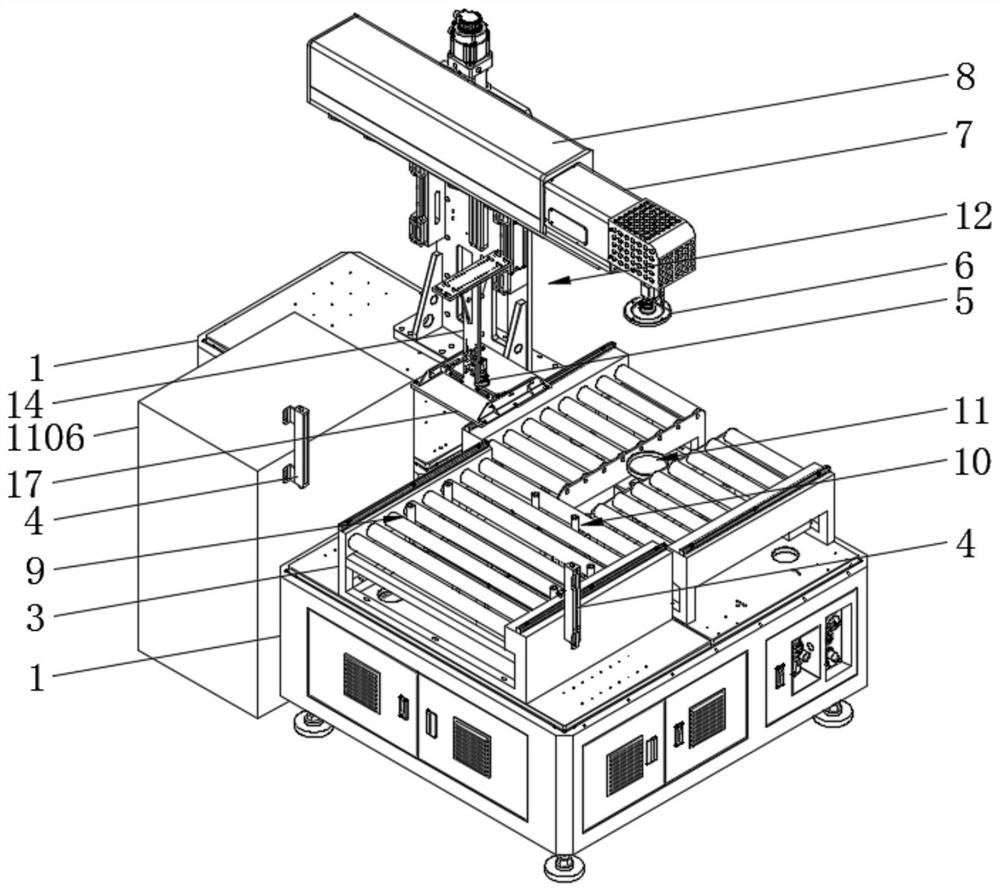

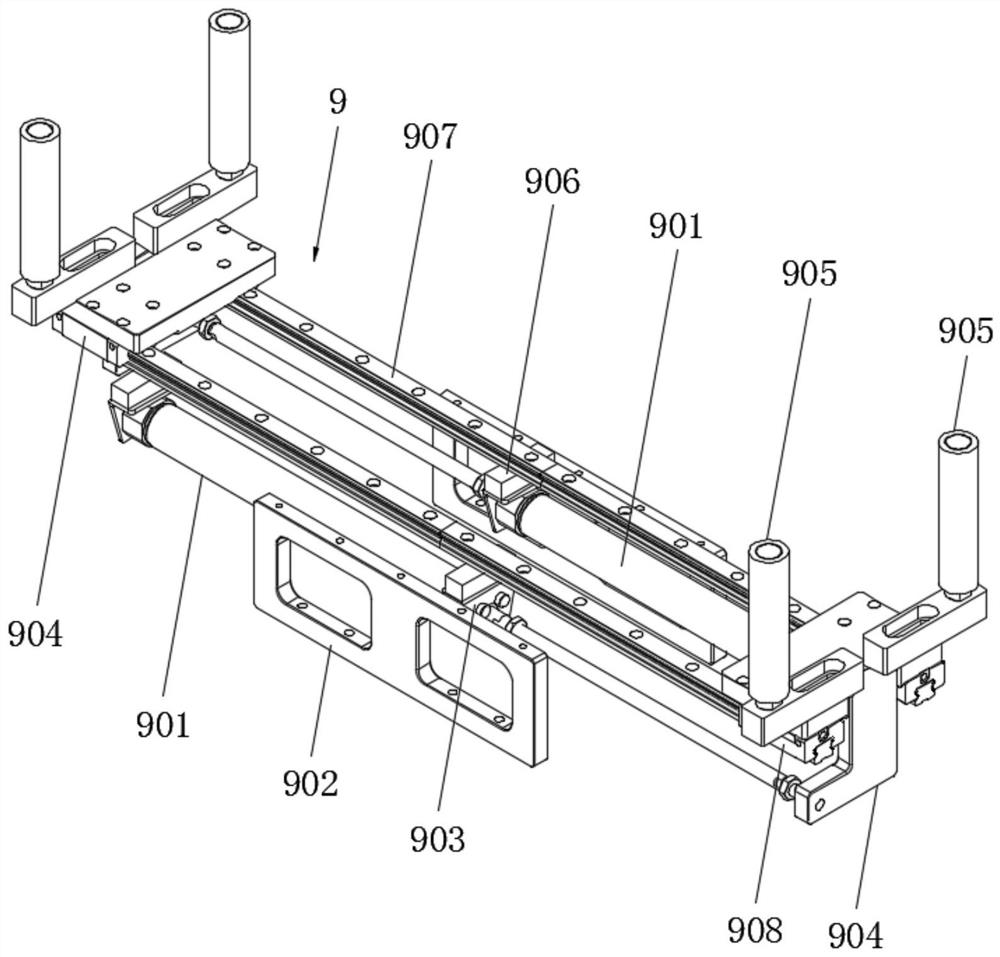

[0036] see figure 2 , the top of the lower frame 1 is successively provided with a height measuring grating 4, a wheel hub holding center mechanism 9, a blocking mechanism 10 and a dust suction mechanism 11 according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com