Method for testing hot bonding strength of PVC (polyvinyl chloride) plastic layer

A testing method and plastic layer technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of low accuracy, complicated operation, and inability to quantitatively measure the bonding strength between layers, achieving high accuracy and simple instrument configuration , the effect of mild test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the thermal bonding strength between two PVC plastic layers with different formulations is tested by using a test method for thermal bonding strength of PVC plastic layers. Wherein, the specific steps are as follows;

[0034] S1: Accurately configure the PVC plastic layer premix according to the accurate formula in Table 1, and mix them uniformly:

[0035] The formula of PVC plastic layer in the embodiment 1 of table 1

[0036] Component / Formulation 1# 2# PVC resin part 1 100 75 PVC resin parts 2 25 Plasticizer DOTP 40 40 calcium powder 20 20 Titanium dioxide 1 1 Calcium zinc heat stabilizer MC420EP 2 2

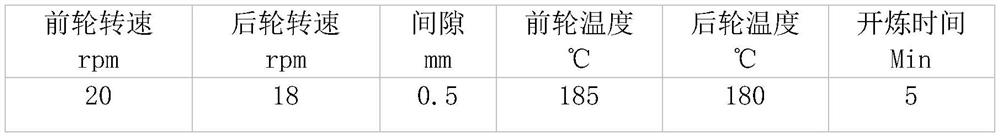

[0037] S2: The premix configured in S1 is kneaded and shaped on a two-roll mill according to the following process parameters to make thin slices:

[0038] The processing parameter of open mill in the embodiment 1 of table 2

[0039]

[0040] S3: cutting the thin sheet made in S2 into s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com