Platinum-rhodium composite electrode for nitrogen-oxygen sensor chip and preparation method of platinum-rhodium composite electrode

A nitrogen-oxygen sensor and composite electrode technology, applied in the direction of electrochemical variables of materials, can solve the problems of reducing product reliability and service life, reducing the catalytic performance conduction of three-phase interface, affecting the performance of zirconia solid electrolyte, etc., so as to eliminate catalysis Efficiency, improving microstructure and mechanical properties, and the effect of shape regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

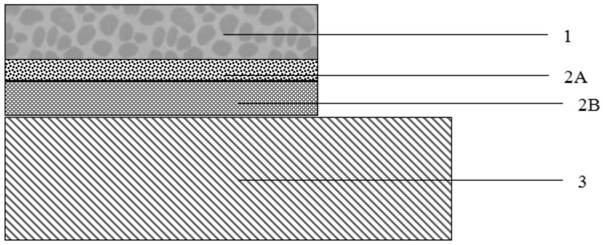

[0057] Such as figure 1 As shown, the present invention discloses a platinum-rhodium composite electrode for nitrogen and oxygen sensor chips. The platinum-rhodium composite electrode includes a porous platinum-rhodium alloy electrode layer and a porous platinum electrode layer provided with a double-layer three-dimensional catalytic network.

[0058] exist figure 1 , specifically includes the following layer structure:

[0059] The porous alumina layer 1 is called the fourth diffusion layer. The oxygen content of the tail gas treated by the auxiliary pump oxygen battery in the second test chamber is extremely low, close to zero. This tail gas mainly contains nitrogen, nitric oxide and other inert gases. At a certain diffusion rate, it reaches the test electrode through the porous diffusion layer, which is the surface of the platinum-rhodium composite electrode.

[0060] Porous platinum-rhodium alloy electrode layer 2A: Nitric oxide decomposes under the platinum-rhodium al...

Embodiment 2

[0067] The electrode slurry of the porous platinum-rhodium alloy electrode layer includes the following components by mass: 30-60 parts of nano-platinum powder, 2-6 parts of rhodium-containing compound, 1-2 parts of protective agent, 8-20 parts of nano-porous carbon powder , 0.1-1 part of dispersant, 3-10 parts of organic binder, 0.1-0.8 part of organic zirconium compound, 0.01-0.4 part of yttrium-containing compound, 0.01-0.6 part of cerium-containing compound, 12-40 parts of organic solvent.

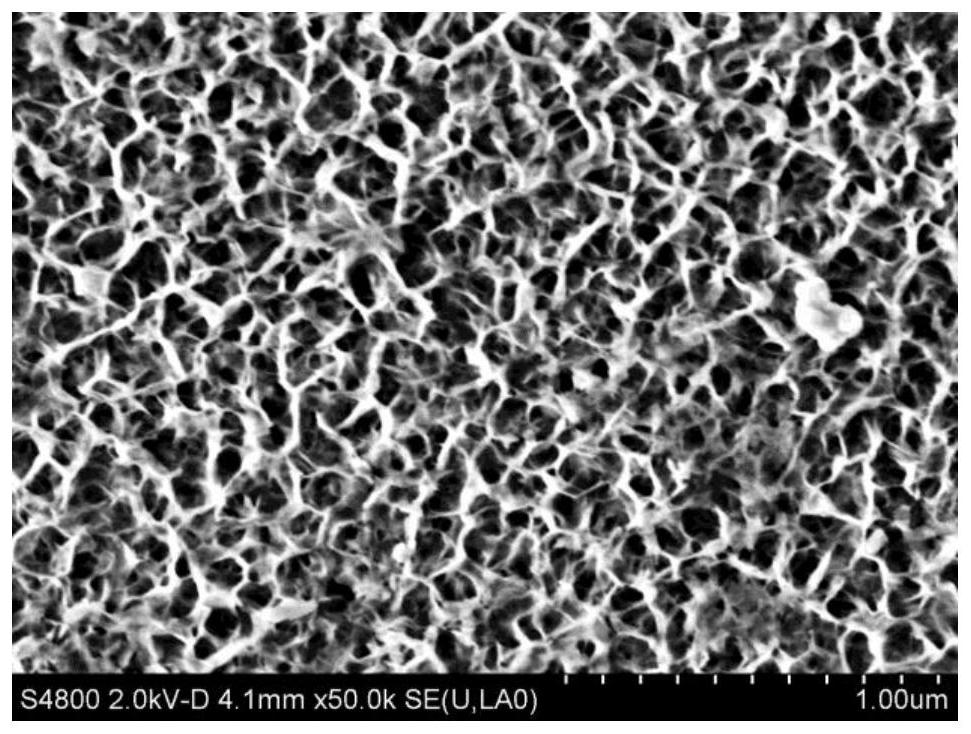

[0068] In the present invention, the appearance of the nano-platinum powder is spherical or approximately spherical or elliptical; the particle diameter is 10-50 nanometers, preferably 30-40 nanometers, and its surface morphology is as follows: Figure 5 shown.

[0069] In the present invention, the rhodium-containing compound is one or a mixture of rhodium carbonyl acetylacetonate, rhodium acetylacetonate, rhodium octanoate dimer or rhodium acetate.

[0070] In the present invention,...

Embodiment 3

[0079] Another aspect of the present invention is to protect the preparation method of the platinum-rhodium composite electrode for the above-mentioned nitrogen and oxygen sensor chip, comprising the following steps: first, nano-platinum powder, rhodium-containing compound, zirconium-containing compound, yttrium compound, cerium compound, protective Dispersing agent, nanomaterial dispersant and organic solvent are dispersed by high-speed dispersing machine; nanoporous carbon powder and organic binder are added for stirring and dispersing; then the slurry dispersed by high-speed dispersing machine is put into a polytetrafluoroethylene cup Put it into the non-contact planetary stirring vacuum degassing machine, and prepare according to the three steps of low-speed dispersion stirring, high-speed dispersion stirring, and vacuum degassing; preparation process parameters: the vacuum degree of the non-contact planetary stirring vacuum degassing machine -0.095 MPa, when stirring at lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap