Pin winding pre-cutting system of network filter and pin winding system thereof

A technology of network filter and pre-cutting, which is applied in coil manufacturing, harmonic reduction device, inductance/transformer/magnet manufacturing, etc. It can solve the problems of uncontrollable breakpoint position and affecting coil stability, etc., to improve efficiency and high The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

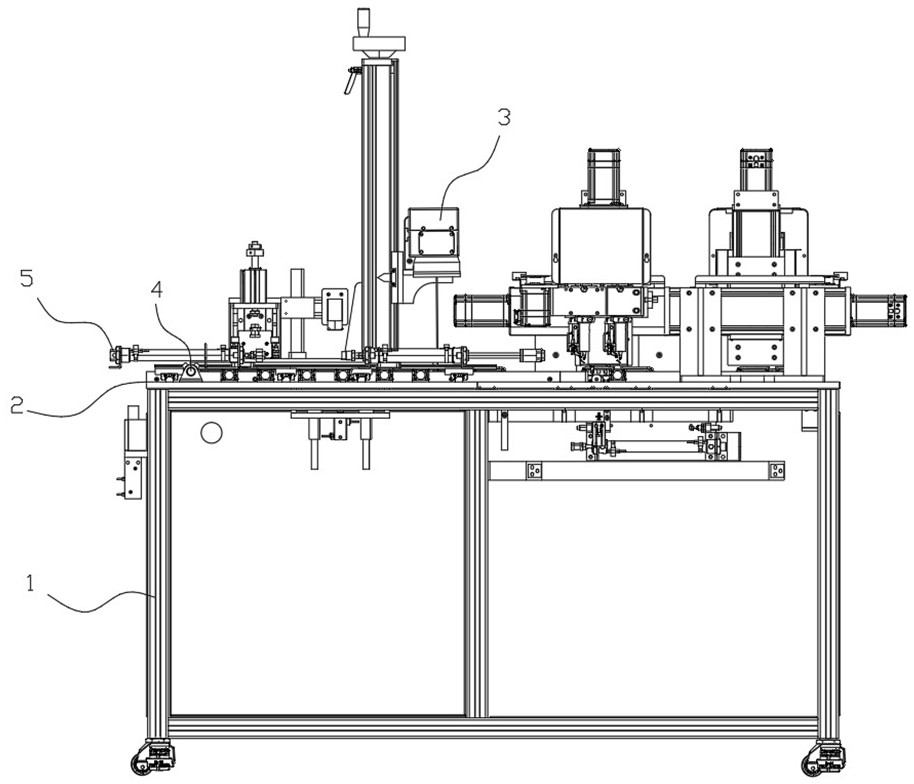

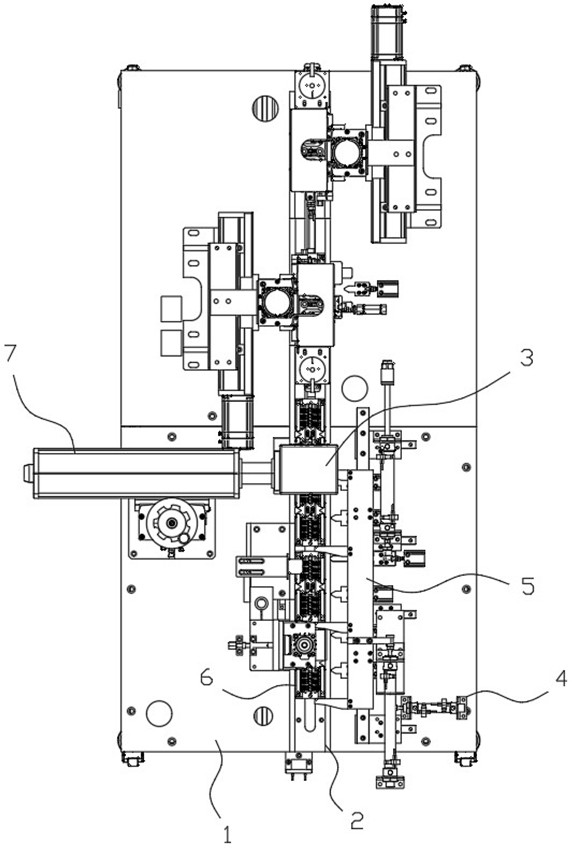

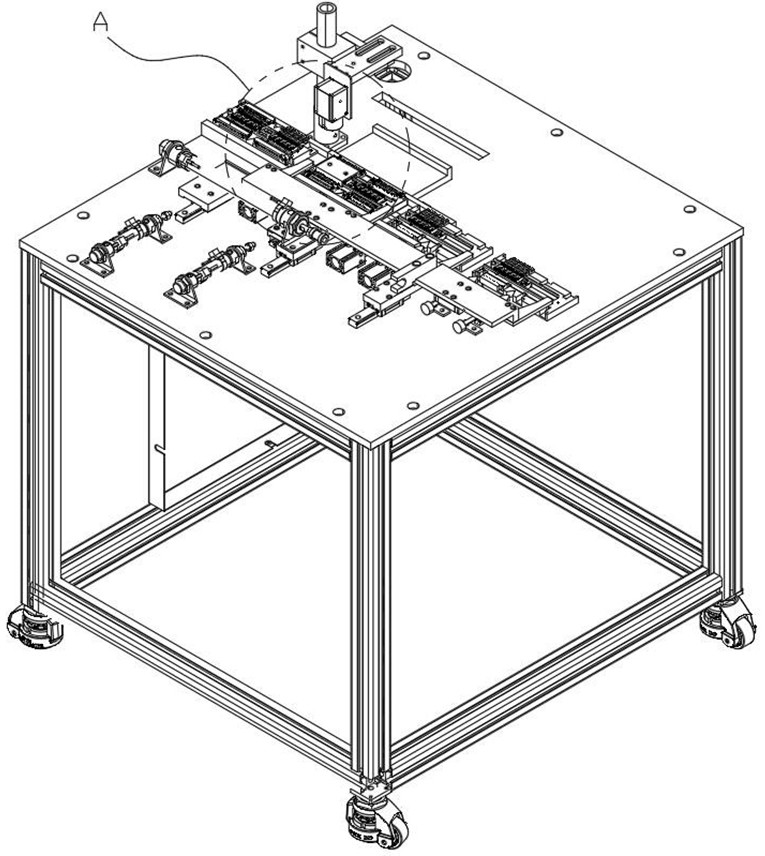

[0043] This embodiment discloses a wire-wound pre-cutting system of a network filter, which is mainly used in the wire-winding process of the network filter, and is used to cut each lead-out enameled wire of the network filter before winding, so that it can be In the subsequent winding process, the excess wire ends can be removed more conveniently.

[0044] Since the system involved in this embodiment is mainly used for making network filters, it is necessary to briefly describe the structure and winding process of network filters involved in this embodiment.

[0045] First, the network filter is Figure 4 It can be seen from the enlarged picture that the network filter in this process is only a semi-finished product, with only one shell, and the back of the shell is open in the process of this embodiment, and a plurality of magnetic rings are arranged in the opening , each magnetic ring will lead to two enameled wires, the process in this embodiment is to straighten and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com