A high-efficiency loading structure suitable for stacked wafers

A high-efficiency, wafer-thin technology that can be used in sustainable manufacturing/processing, climate sustainability, and final product manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

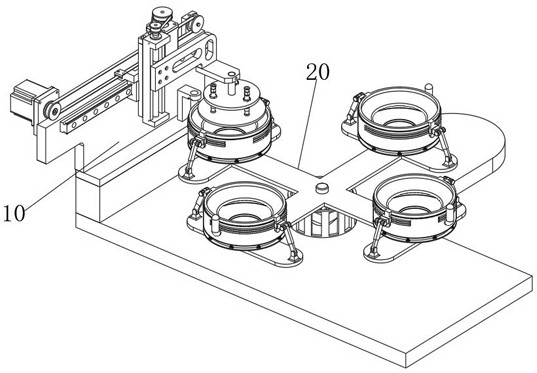

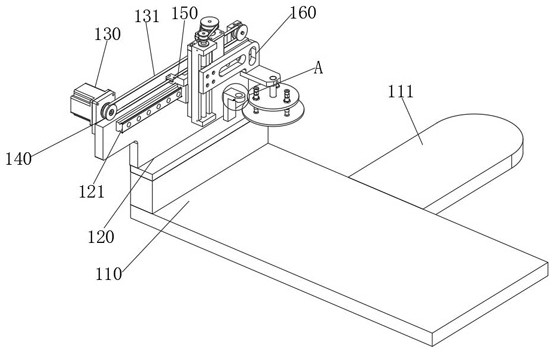

[0044] see Figure 1-Figure 10 As shown, an efficient feeding structure suitable for stacking wafers is provided, including a conveying device 10 and a storage assembly 20 installed on one side of the conveying device 10. The conveying device 10 at least includes:

[0045] The operating table 110, the operating table 110 has an L-shaped structure;

[0046] Side plate 120, the side plate 120 is arranged at the top of the console 110, and a lateral slide 121 is arranged at the top position of the side surface of the side plate 120;

[0047] a first servo motor 130, the first servo motor 130 is arranged at the top position of the other side of the side plate 120, and a first belt 131 is arranged on the side of the first servo motor 130;

[0048] The rotating shaft 140 is provided with a pair, the two rotating shafts 140 are respectively arranged on both sides of the top end of the side plate 120 , and the two rotating shafts 140 are respectively rotatably connected with the two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com