Flexibly designable converter cell

A converter and control unit technology, applied in the direction of output power conversion device, irreversible AC power input conversion to DC power output, electrical components, etc., can solve the problems of high logistics and storage costs, increased production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

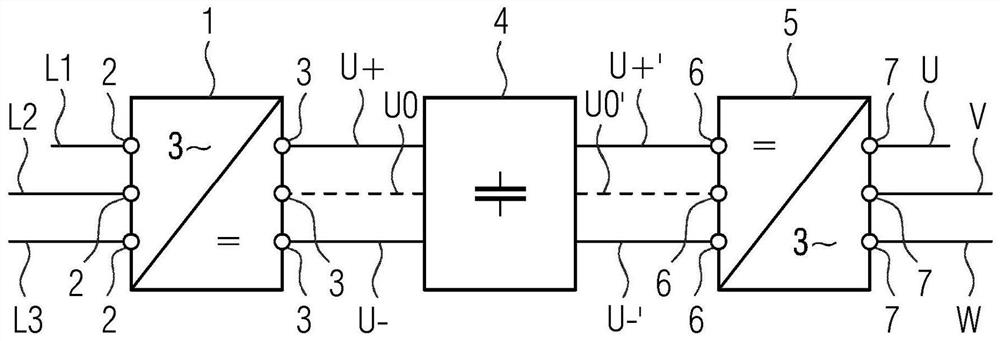

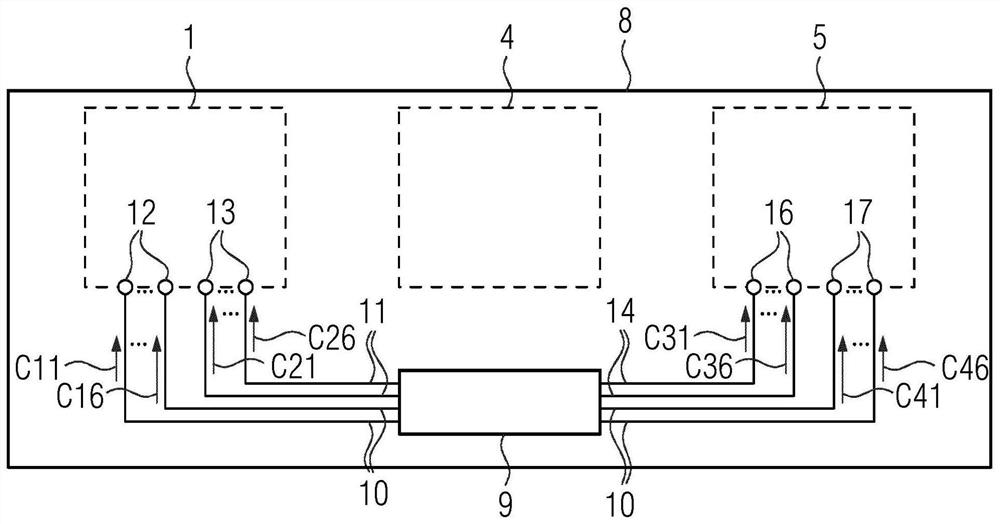

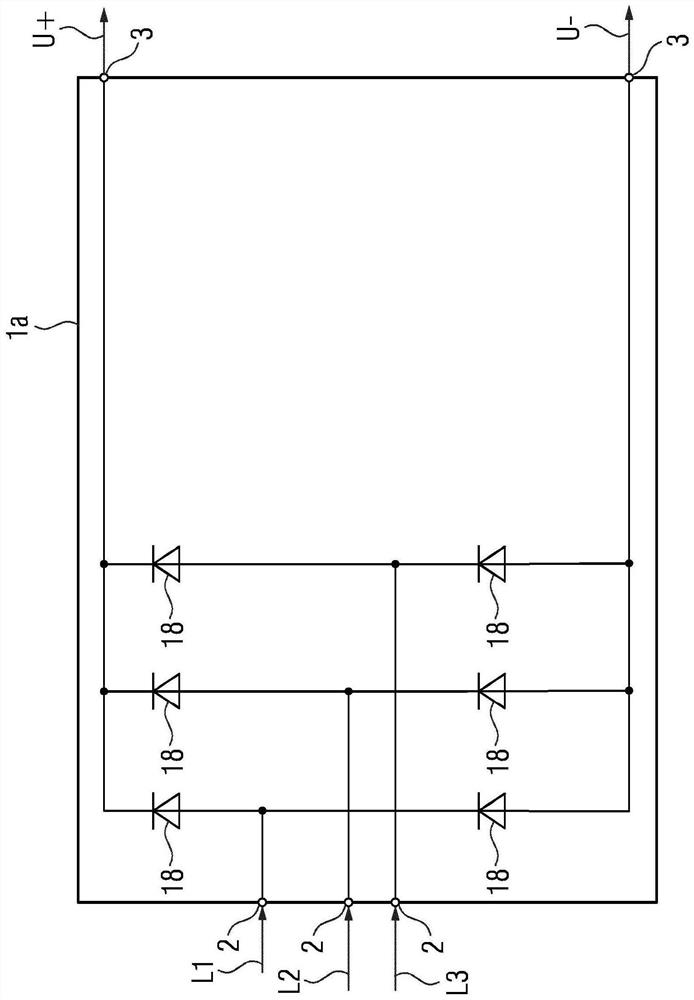

[0040] according to figure 1 , the converter unit firstly has a rectifier unit 1 as the basic functional unit. The AC voltages L1 , L2 , L3 (phases), typically the three AC voltages of a three-phase grid, are fed to the rectifier unit 1 via the first power connection 2 of the rectifier unit 1 . The rectifier unit 1 is able to convert the AC voltage fed to it into at least two DC voltage potentials U+, U−. The rectifier unit 1 outputs DC voltage potentials U+, U− via the second power connection 3 . Possible designs of the rectifier unit 1 will be explained in more detail later.

[0041] The output DC voltage potentials U+, U− are fed to the DC voltage connection 4 . The DC voltage connection 4 is another main functional unit of the converter unit. The DC voltage connection device 4 usually has a capacitor network internally in order to smooth the DC voltage potentials U+, U−.

[0042] The direct voltage potentials U+, U− are fed to the inverter unit 5 . The inverter unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com