Height-adjustable shrub pruning device

A pruning device and height adjustment technology, which is applied to electric pruning saws, agricultural machinery and implements, gardening, etc., can solve the problems of reduced pruning efficiency, falling to the ground, increasing the workload of operators, etc., and achieve the goal of improving sliding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

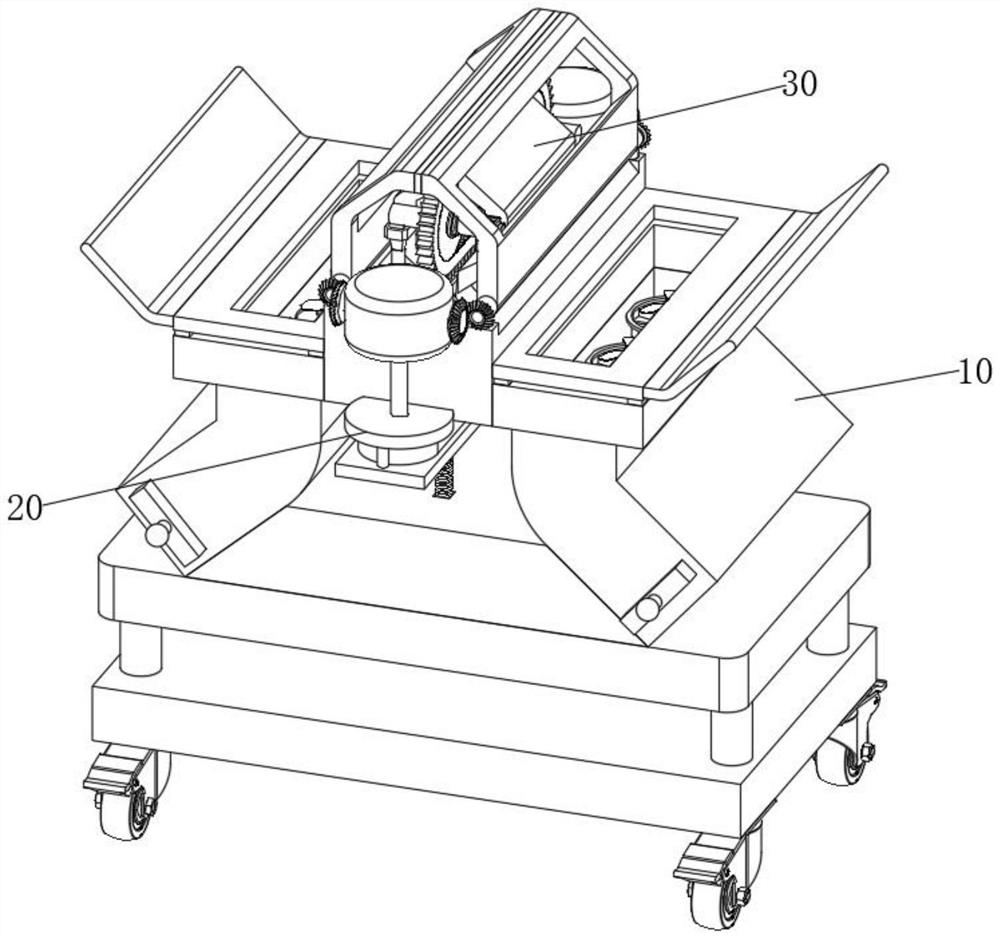

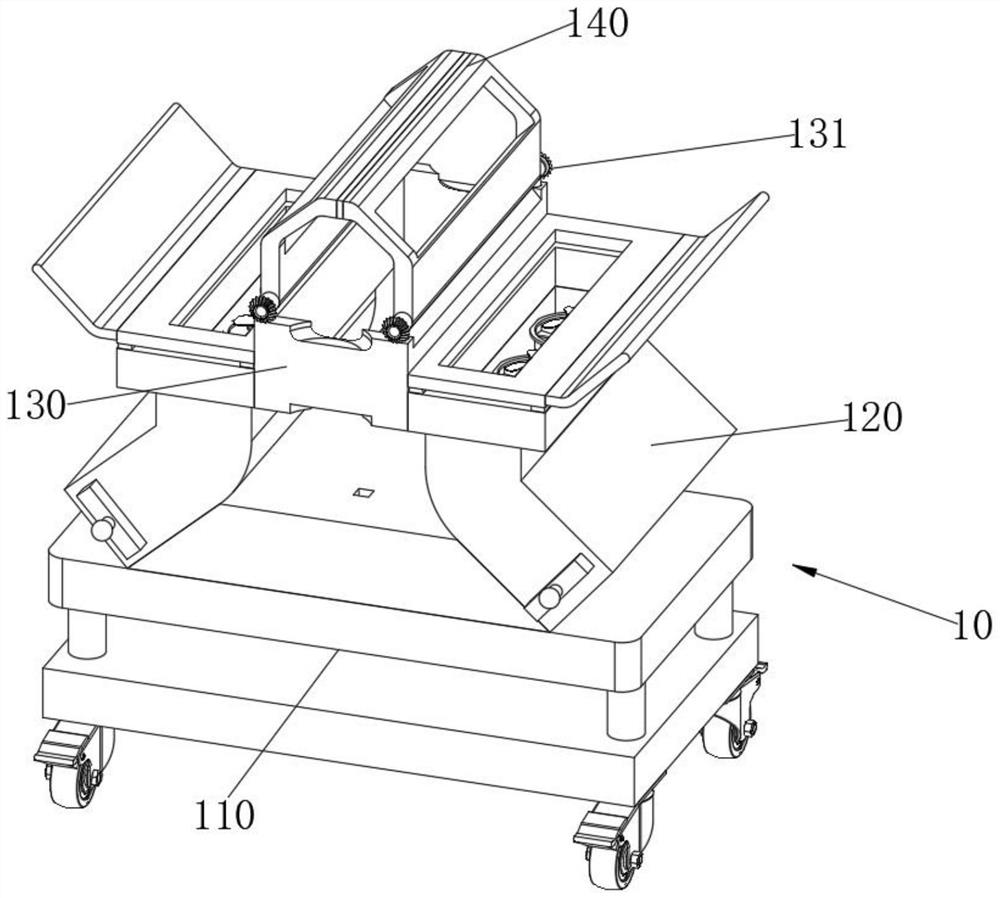

[0043] see Figure 1-Figure 10 As shown, a height-adjustable bush pruning device is provided, including a support device 10, a pair of transmission assemblies 20 installed on both sides of the top of the support device 10, and a cutting assembly 30 installed in the middle of the top of the support device 10. The support device 10 including at least:

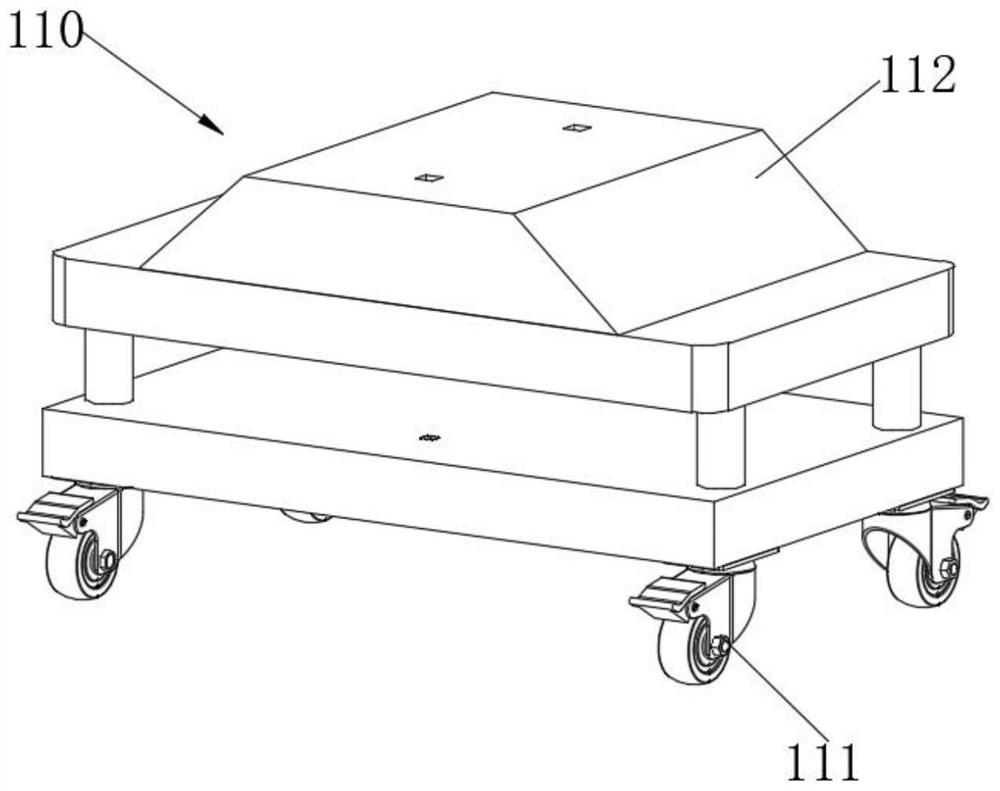

[0044] Backing plate 110, the bottom end of backing plate 110 is provided with several universal wheels 111;

[0045] A collection box 120, the collection box 120 is arranged on both sides of the top of the backing plate 110, and the top of the collection box 120 is provided with a top groove 121;

[0046] Operating table 130, the two sides of the operating table 130 are fixedly connected with the sides of the two collection boxes 120 respectively, the top of the operating table 130 is a hollow structure, both sides of the top of the operating table 130 are provided with a rotating shaft 131, and both ends of the rotating shaft 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com