Cleaning device based on rice processing system

A cleaning device and rice processing technology, applied in the direction of using liquid cleaning method, drying gas arrangement, cleaning method and utensils, etc., can solve the problems of inability to dry rice, low efficiency of manual cleaning, and low efficiency, so as to promote cleaning Effect, improve the effect of water washing, improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

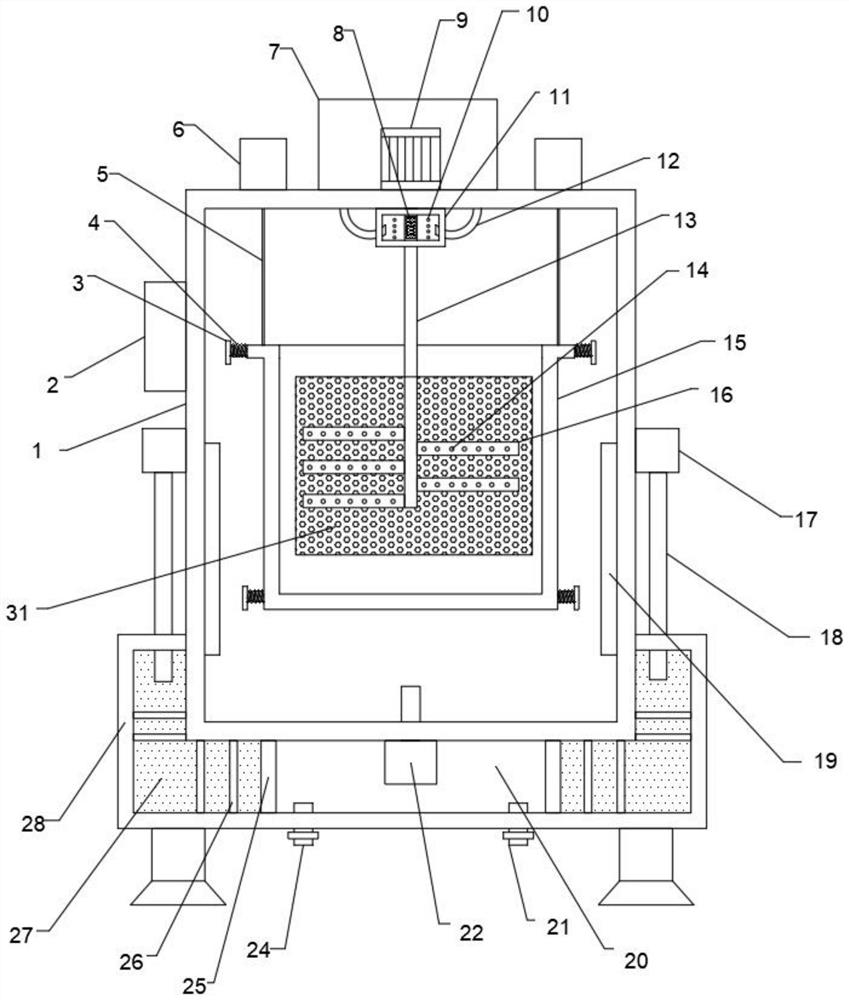

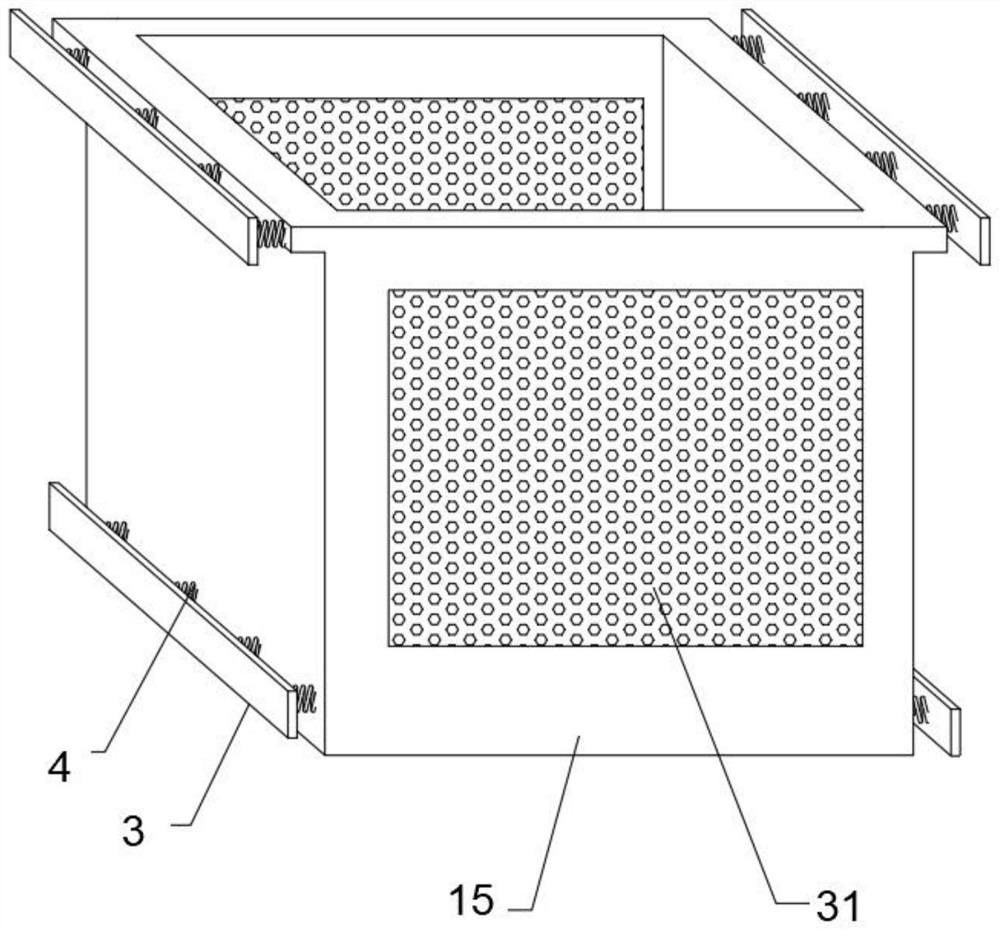

[0023] refer to Figure 1-2 , a cleaning device based on a rice processing system, comprising a box body 1, an electric control box 2 is fixedly connected to the outer wall of one end of the box body 1, a loading box 15 is arranged on the inner wall of the box body 1, and a lifting mechanism is fixedly connected to the top outer wall of the loading box 15, Both outer walls of the loading box 15 are fixedly connected with liquid leakage plates 31, the top of the box body 1 is fixedly connected with a motor 9, the bottom of the motor 9 is fixedly connected with a rotating shaft 13, and the outer wall of the rotating shaft 13 is fixedly connected with a plurality of stirring rods 16, stirring rods 16 is located in the loading box 15, the top of the box 1 is provided with a drying mechanism, the bottom of the box 1 is provided with a bottom box 28, the bottom of the loading box 15 is provided with a second water pump 22, the second water pump 22 is fixedly connected to the box 1, a...

Embodiment 2

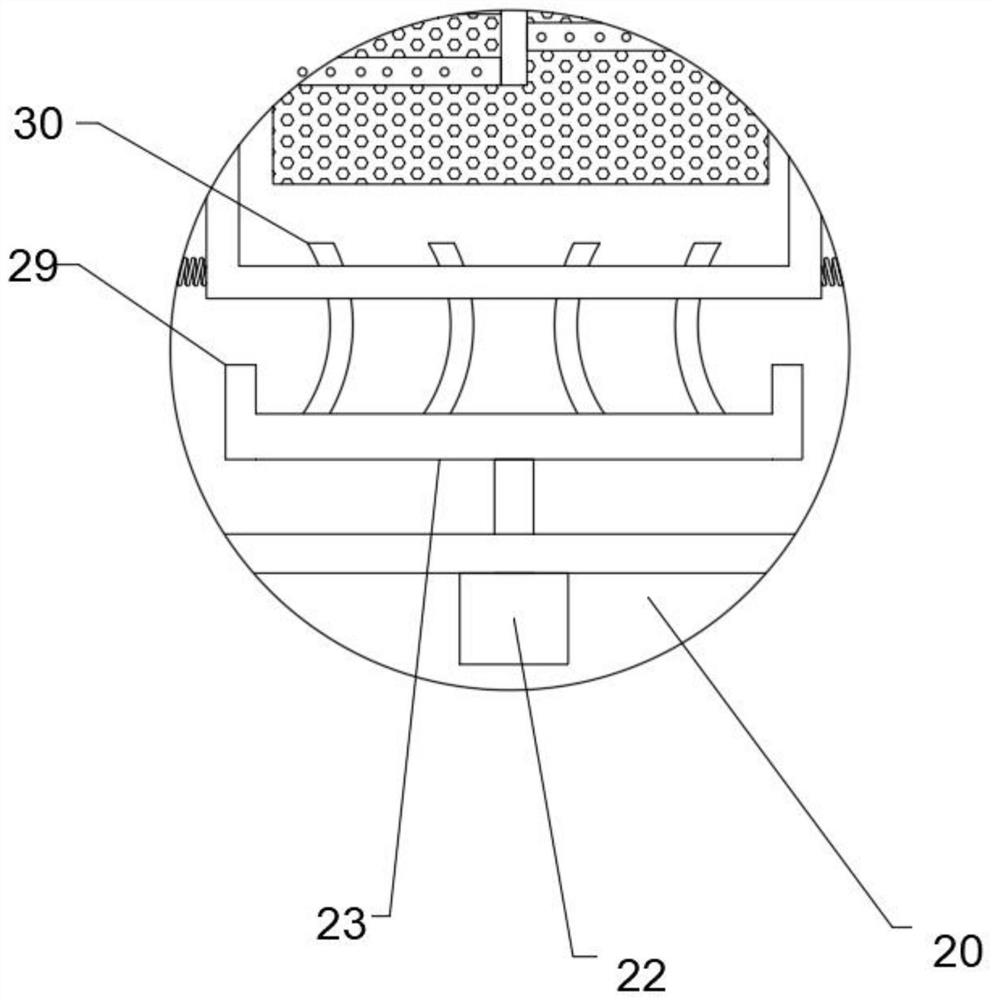

[0030] refer to Figure 2-3 , a cleaning device based on a rice processing system, the top of the second water pump 22 is fixedly connected with a liquid distribution pipe 23, the top of the liquid distribution pipe 23 is fixedly connected with a plurality of liquid guide hoses 30, the top of the liquid guide hose 30 and the loading box 15 For fixed connection, high-pressure nozzles 29 are provided at both ends of the liquid distribution pipe 23 .

[0031] Working principle: by setting the second water pump 22, the water flow is introduced into the liquid distribution pipe 23, and the water flow is directly passed into the loading box 15 by setting a plurality of liquid guide hoses 30, so as to further improve the water flow flushing effect, by setting the high-pressure nozzle 29 The shaking amplitude of the loading box 15 can be further increased, thereby improving the washing efficiency of the rice in the loading box 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com