Synchronizer oil charge self-adaptive control method and device

A technology of self-adaptive control and synchronizer, applied in transmission control, clutch, components with teeth, etc., can solve problems such as poor oil filling effect, and achieve the effect of improving oil filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

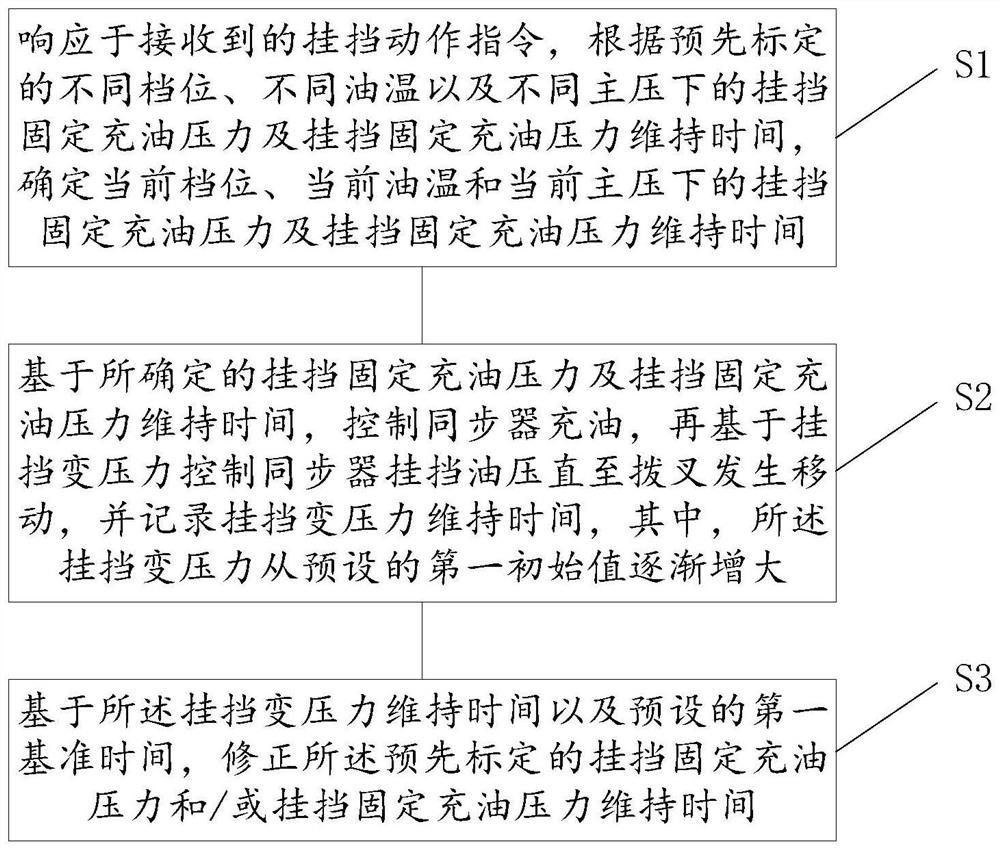

[0062] see figure 1 , a synchronizer oil filling adaptive control method, comprising:

[0063] Step S1: In response to the received gear-engaging action command, determine the current gear position according to the pre-calibrated fixed oil-charging pressure of different gear positions, different oil temperatures, and different main pressures and the maintenance time of the fixed oil-charging pressure of gear-engaging , the current oil temperature and the current main pressure of the fixed oil charge pressure in gear and the maintenance time of the fixed oil charge pressure in gear;

[0064] Step S2: Based on the determined fixed oil filling pressure for in-gear and the maintenance time of the fixed oil-fill pressure for in-gear, control the oil filling of the synchronizer, and then control the oil pressure for in-gear of the synchronizer based on the variable pressure of the in-gear until the shift fork moves, and record The gear change pressure maintenance time, wherein, the...

Embodiment 2

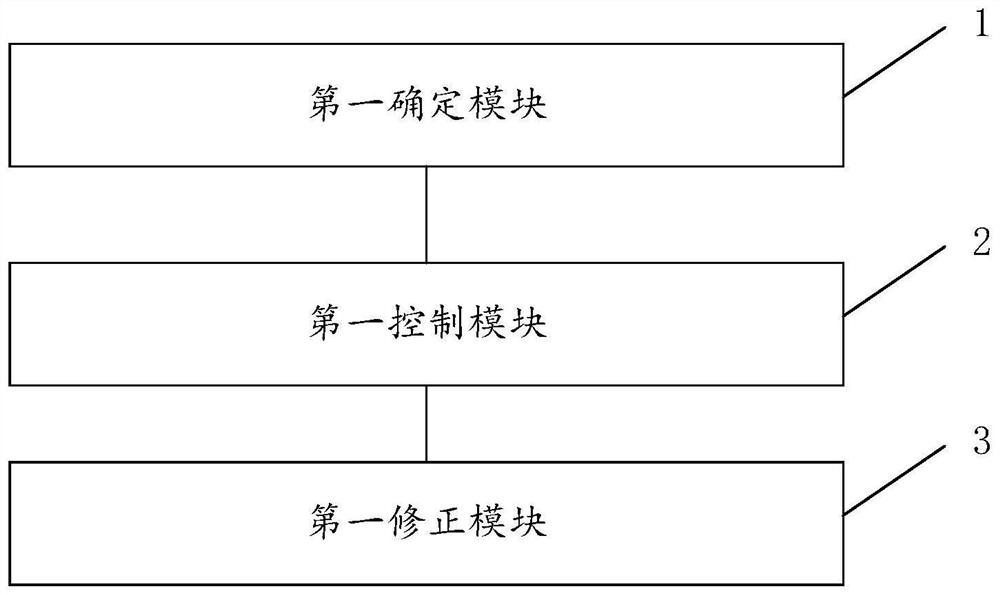

[0105] see image 3 , a synchronizer oil filling adaptive control device, comprising:

[0106] The first determining module 1 is configured to respond to the received gear-engagement action instruction, according to the pre-calibrated gear-shifting fixed oil-charging pressure and gear-shifting fixed oil-charging pressure maintenance time under different gear positions, different oil temperatures and different main pressures , to determine the current gear position, current oil temperature and current main pressure, the fixed oil charge pressure in gear and the maintenance time of the fixed oil charge pressure in gear;

[0107] The first control module 2 is used to control the oil filling of the synchronizer based on the determined fixed oil charging pressure and the maintenance time of the fixed oil charging pressure of the gear, and then control the oil pressure of the synchronizer based on the variable pressure of the gear until the shift fork A movement occurs, and the tim...

Embodiment 3

[0145] First, the parameters in this embodiment are described:

[0146] P 1 : The first stage oil filling pressure, divided into the first stage gear oil filling pressure P 1_apply , Oil filling pressure P in the first stage 1_release ;

[0147] P 1_apply : The oil filling pressure in the first stage, the initial value of the pressure is the calibration value, which distinguishes different gears, oil temperature and main pressure;

[0148] P 1_release : In the first stage, the gear is removed and the oil filling pressure is selected. The initial value of the pressure is the calibration value, which distinguishes different gears, oil temperature and main pressure;

[0149] P' 1 : The first-stage oil-filling pressure corrected based on the shifting time of the shift fork;

[0150] k1: correction coefficient of oil filling pressure in the first stage;

[0151] T 1 : The maintenance time of the oil filling pressure in the first stage, which is divided into the maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com