Special small coal bunker suitable for deep peak regulation of 600MW unit

A small coal bunker, deep technology, used in packaging, loading/unloading, large containers, etc., can solve the problem of difficulty in switching between different coal types, and achieve the effect of rapid switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

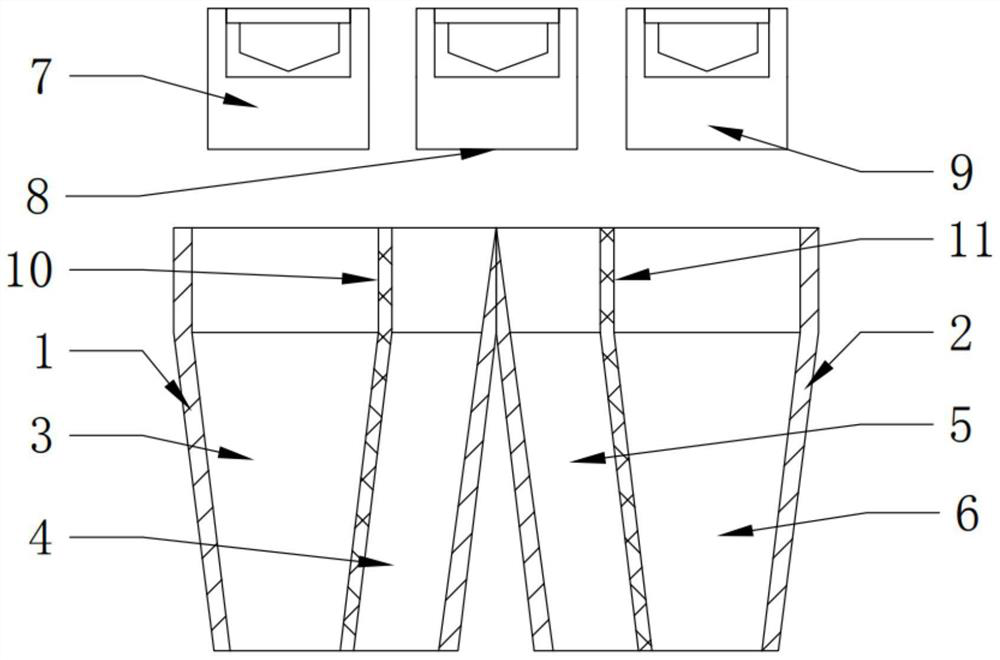

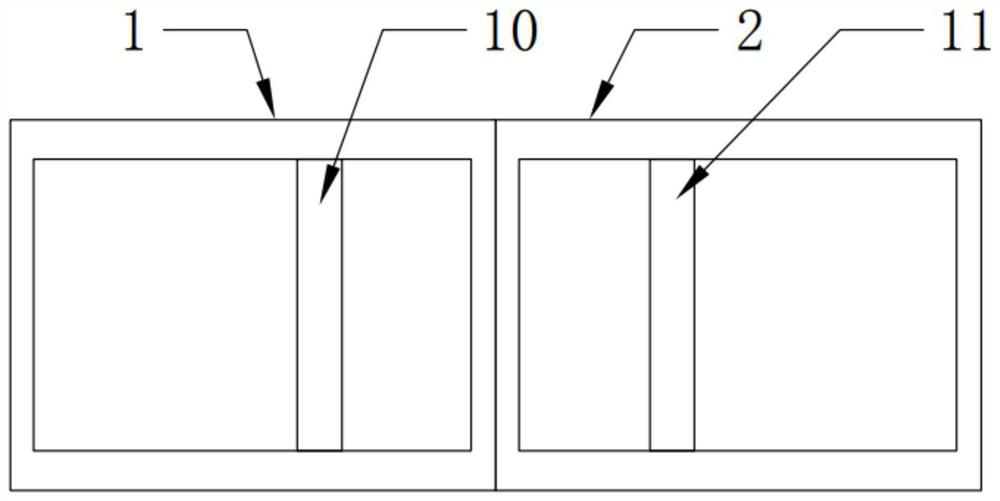

[0036] Such as figure 1 and figure 2 As shown, a special small coal bunker suitable for deep peak regulation of 600MW units includes two first coal bunkers 1 and second coal bunkers 2 arranged side by side. The first coal bunker 1 is provided with a first coal channel 3 and a The second coalway 4, the third coalway 5 and the fourth coalway 6 are arranged in the second coal bunker 2, the first coal plow 7 is arranged above the first coalway 3, the second coalway 4 and the third coalway A second coal plow 8 is arranged above the road 5, a third coal plow 9 is arranged above the fourth coal passage 6, and the first coal plow 7, the second coal plow 8 and the third coal plow 9 are arranged side by side;

[0037] A first dividing plate 10 is vertically arranged between the first coalway 3 and the second coalway 4, a second dividing plate 11 is vertically arranged between the third coalway 5 and the fourth coalway 6, and the first dividing plate 10 is adapted to the inner wall of...

Embodiment 2

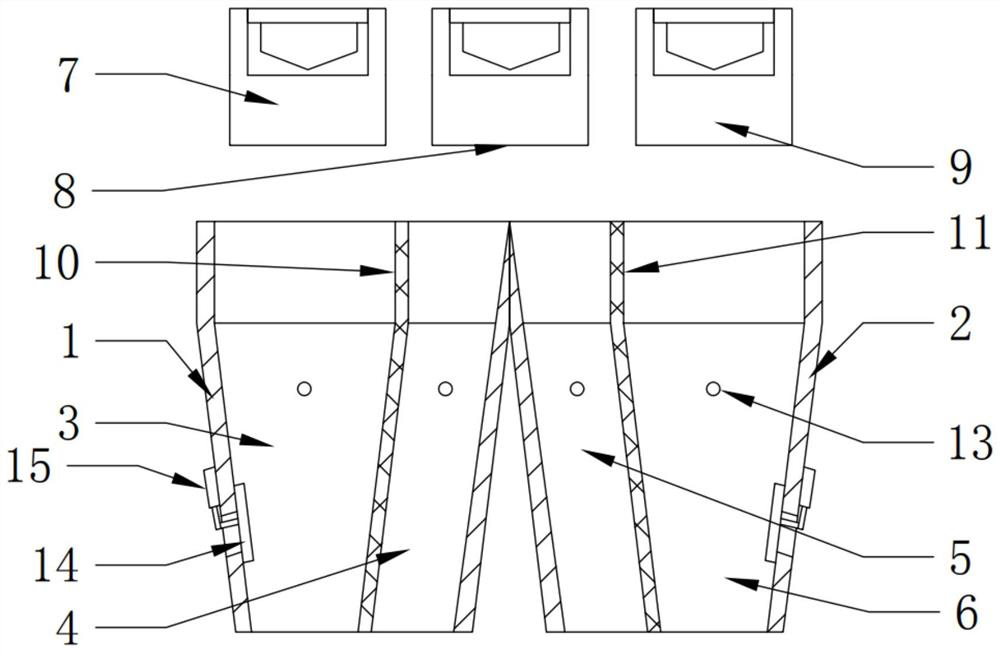

[0043] Such as image 3 and Figure 4 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, and this embodiment is further optimized on the basis of Embodiment 1: the first coalway 3, the second coalway 4, the third coalway 5 and the fourth coalway All are provided with breaking up stick 13 in 6, and breaking up stick 13 horizontal settings, the quantity of breaking up stick 13 is more than one.

[0044] Specifically, due to the humidity of the environment or other reasons, loose coal or coal powder condenses into agglomerates, in order to prevent the agglomerated falling coal from blocking the outlet, the first coal channel 3, the second coal channel 4, and the third coal channel 5 and the fourth coalway 6 are fixedly connected with a breaking stick 13, and the breaking stick 13 is fixed perpendicular to the inner walls of the first coalway 3, the second coalway 4, the third coalway 5 and the fourth coalway 6, The number of loose sticks 13 ...

Embodiment 3

[0048] Such as Figure 5 As shown, the structure of this embodiment is roughly the same as that of Embodiment 2, and this embodiment is further optimized on the basis of Embodiment 2: the upper ends of the opposite side of the second coalway 4 and the third coalway 5 are fixedly connected and provided with a buffer Article 16.

[0049] Specifically, in order to prevent the coal falling from the second coal plow 8 from colliding with the upper ends of the second coal passage 4 and the upper ends of the third coal passage 5 from colliding and splashing, the upper end of the side of the second coal passage 4 and the third coal passage 5 is fixed Connected together and bonded with a buffer strip 16, the buffer strip 16 is a rubber strip, on the one hand, the setting of the buffer strip 16 can abut and buffer the falling coal to prevent the falling coal from splashing around, and on the other hand, the buffer strip 16 can prevent Coal accumulation at the upper end of the side wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com